Preparation method for MFI/MOR composite zeolite molecular sieve catalyst without binder

A composite zeolite, binder-free technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low activity and poor strength, achieve high mechanical strength, avoid mechanical mixing, structure regular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 20 grams of MOR zeolite (SiO 2 / Al 2 o 3 The molar ratio is 30) and 6.2 grams of alumina, adding 60 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100° C. for 3 hours.

[0024] Add 20 grams of ethylenediamine and 10 grams of distilled water to a 200 ml autoclave in advance, place the cylindrical shaped sample prepared above in the reaction kettle, the catalyst sample is not in contact with the solution in the kettle, seal the autoclave and put it into an oven at 150°C Take it out after crystallization for 80 hours, wash it with water until it is colorless, bake it in an oven at 120°C for 2 hours, then put it in a muffle furnace and heat it up to 400°C for 10 hours to prepare a binder-free MFI / MOR composite zeolite molecular sieve.

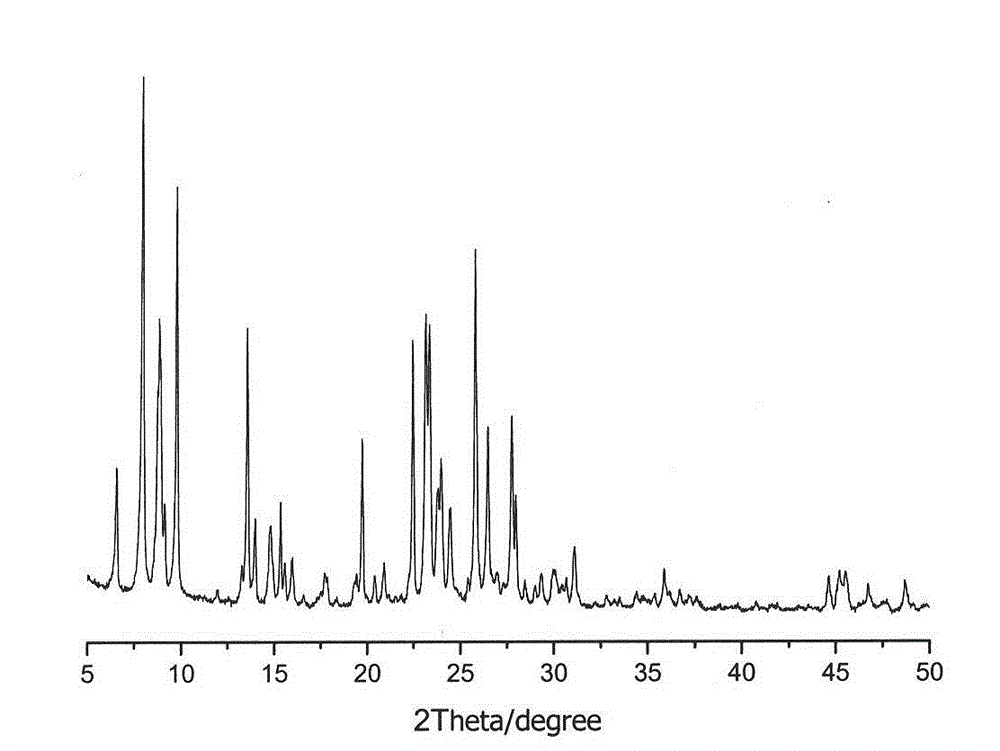

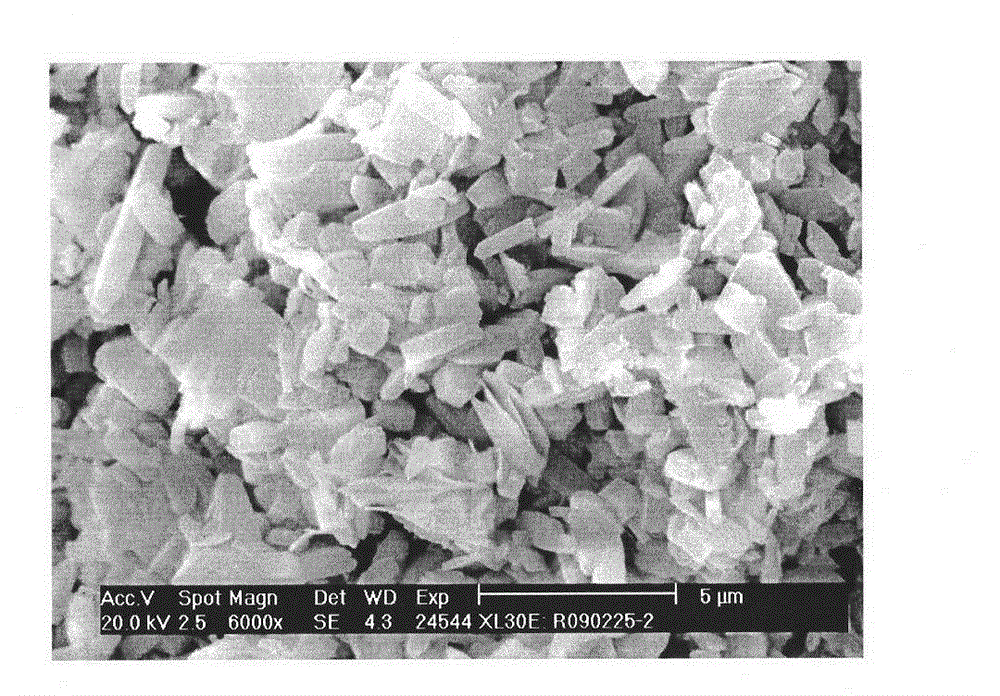

[0025] The XRD pattern shows that the product contains the characteristic diffraction peaks of MFI zeolite molecular sieve and MOR zeolite molecular sieve, and th...

Embodiment 2

[0027] Weigh 5 grams of MOR zeolite (SiO 2 / Al 2 o 3 Molar ratio is 20) and 2.8 grams of sodium metaaluminate, add 90 grams of silica sol (SiO 2 The mass percentage is 40%) for kneading and molding, and the shaped catalyst is baked at 100° C. for 3 hours.

[0028]Add 5 grams of ethylenediamine, 5 grams of triethylamine and 10 grams of distilled water in advance in a 200 ml autoclave, place the cylindrical shaped sample prepared above in the reaction kettle, the catalyst sample is not in contact with the solution in the kettle, and after the autoclave is sealed Put it in an oven, crystallize at 130°C for 200 hours, take it out, wash it until colorless, put it in an oven at 120°C for 2 hours, then put it in a muffle furnace and heat it up to 450°C for 8 hours to prepare a binder-free MFI / MOR composite zeolite molecular sieve.

[0029] The XRD pattern shows that the product contains the characteristic diffraction peaks of MFI zeolite molecular sieve and MOR zeolite molecular...

Embodiment 3~6

[0031] According to the method of embodiment 1, select SiO respectively 2 / Al 2 o 3 For MOR zeolites with molar ratios of 40, 60, 80 and 100, the preparation process remains unchanged, the raw material composition and preparation conditions are shown in Table 1, and the results of the binder-free MFI / MOR composite zeolite molecular sieves prepared are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com