Coking wastewater treatment method

A technology for coking wastewater and treatment methods, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, and multi-stage water/sewage treatment, etc. Insufficient, low concentration of biodegradable COD, etc., to achieve the effect of improving denitrification efficiency and biodegradability, convenient management, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

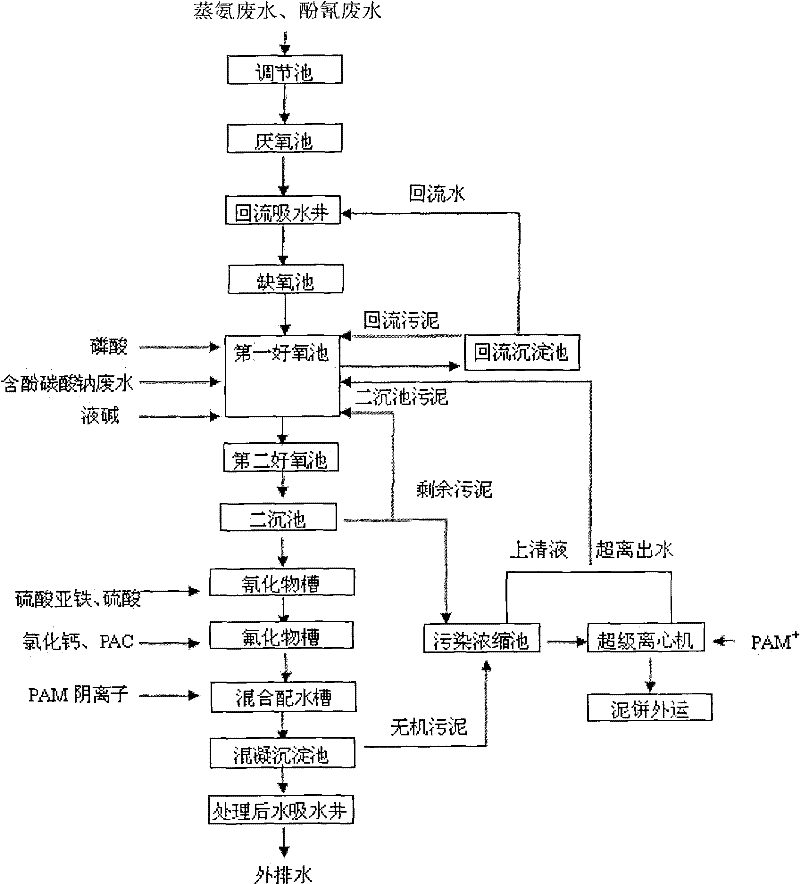

[0051] Ammonia distillation wastewater and phenol cyanide wastewater enter the regulating tank and mix evenly, with a treatment capacity of 90-120m 3 / h, ammonia distillation wastewater is about 48m 3 / h, the initial rainwater is about 60m 3 / h, domestic wastewater about 2m 3 / h, the average value of COD in the effluent of the regulating pool is 1525mg / l, the average value of ammonia nitrogen is 45.14mg / l, the average value of phenol is 62.03mg / l, and the average value of total cyanide is 28.96mg / l.

[0052] After the raw water enters the anaerobic pool for acidification and hydrolysis, it flows to the backflow water suction well, and is pumped into the anoxic pool together with the backflow water for denitrification. , Liquid caustic soda, return sludge, secondary sedimentation tank sludge. Most of the mud-water mixture in the first aerobic tank flows to the reflux sedimentation tank for mud-water separation, and all the sewage flows back to the reflux water suction well, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com