Core-shell structured silicate luminescent material and preparation method thereof

A technology of core-shell structure and luminescent materials, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., and can solve the problems of poor luminous intensity of phosphor powder, uneven particle distribution, and inconsistent particle size of powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The preparation method of the core-shell structure silicate luminescent material according to the embodiment of the present invention comprises the following steps:

[0019] use method coated SiO 2 Nanospheres, that is, after mixing ethanol, deionized water and ammonia water, adding tetraethyl orthosilicate to obtain SiO 2 nanospheres; again

[0020] According to the structural formula Ln 2-x SiO 5 :Tb x @SiO 2 Add the salt solution of Ln and Tb in the stoichiometric ratio of the corresponding elements, mix evenly, add dropwise oxalic acid solution to form a white precipitate, and then adjust the pH value of the reaction system to weak alkalinity with ammonia water, and then carry out formation, filtration, and dehydration in sequence. Wash the precipitate with ionic water and absolute ethanol, and finally dry to obtain the precursor;

[0021] The precursor is placed in a muffle furnace for heat treatment and reduction treatment, and then cooled to obtain the fi...

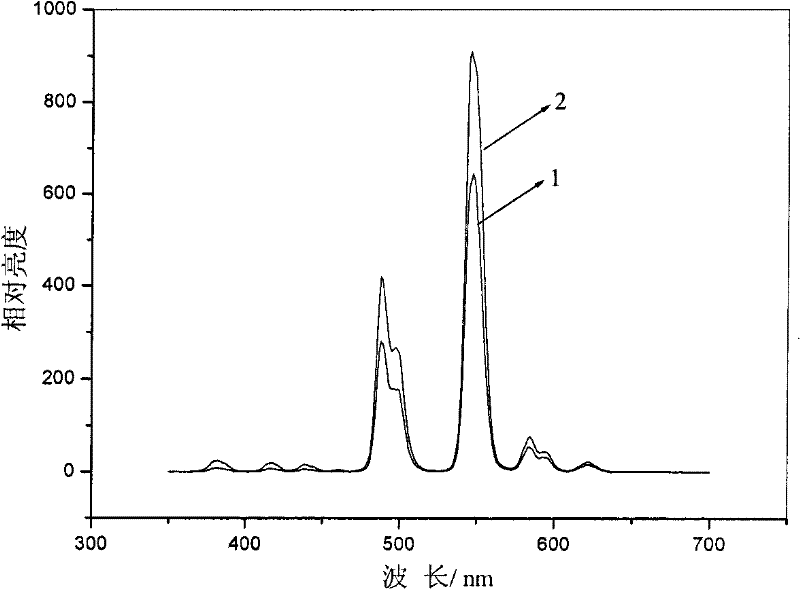

Embodiment 1

[0027] Preparation of Sc by Co-precipitation 1.95 SiO 5 :Tb 0.05 @SiO 2 :

[0028] Take 30mL absolute ethanol in a conical flask, then add 8mL deionized water and 10mL ammonia water, stir evenly, add 1.2mL tetraethyl orthosilicate while stirring, after reacting for 6 hours, add 7.8mL 1mol / LScCl 3 and 4mL 0.05mol / L TbCl 3 After stirring evenly, add 15mL of 1mol / L oxalic acid solution dropwise to form a white precipitate, then adjust the pH value to 8-9 with ammonia water, then stir for 3 hours, age, filter, and finally use deionized water and Washed three times with absolute ethanol, and dried to obtain the precursor. The precursor was heat treated in a muffle furnace at 1600 °C for 1 h, and then in a tube furnace at 95% N 2 +5%H 2 Sintering at 1000°C for 8 hours in reducing atmosphere, cooling to room temperature to obtain Sc 1.95 SiO 5 :Tb 0.05 @SiO 2 Luminescent material.

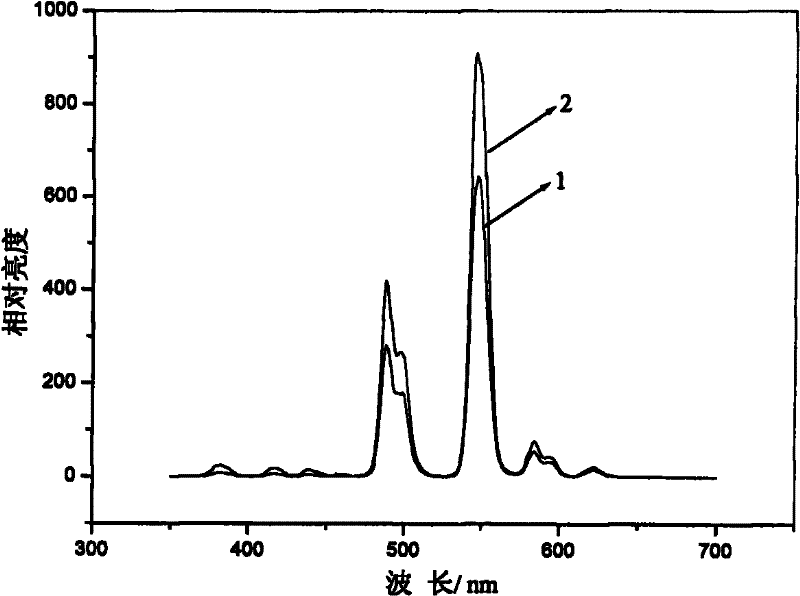

Embodiment 2

[0030] Preparation of Gd by Co-precipitation 1.80 SiO 5 :Tb 0.20 @SiO 2 :

[0031] Take 20mL absolute ethanol in a conical flask, then add 6mL deionized water and 3mL ammonia water, stir evenly, add 1.5mL tetraethyl orthosilicate while stirring, after reacting for 6 hours, add 3.6mL 2mol / LGd(NO 3 ) 3 and 4mL 0.20mol / L Tb(NO 3 ) 3After stirring the solution evenly, add 15mL of 1mol / L oxalic acid solution dropwise to form a white precipitate, then adjust the pH value to 8-9 with ammonia water, then stir for 3 hours, age, filter, and finally use deionized water and Washed three times with absolute ethanol, and dried to obtain the precursor. The precursor is placed in a muffle furnace for heat treatment at 900°C for 12 hours, then sintered in a muffle furnace at 1400°C for 4 hours in a carbon powder reducing atmosphere, and cooled to room temperature to obtain Gd 1.80 SiO 5 :Tb 0.20 @SiO 2 Luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com