Treatment method of sewage containing coal tar

A treatment method, coal tar technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve the problems of unreported, waste of energy level, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

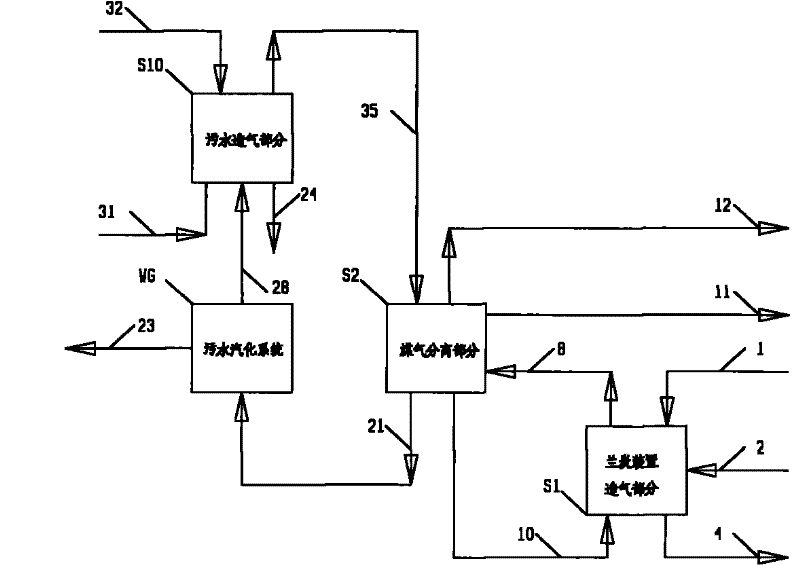

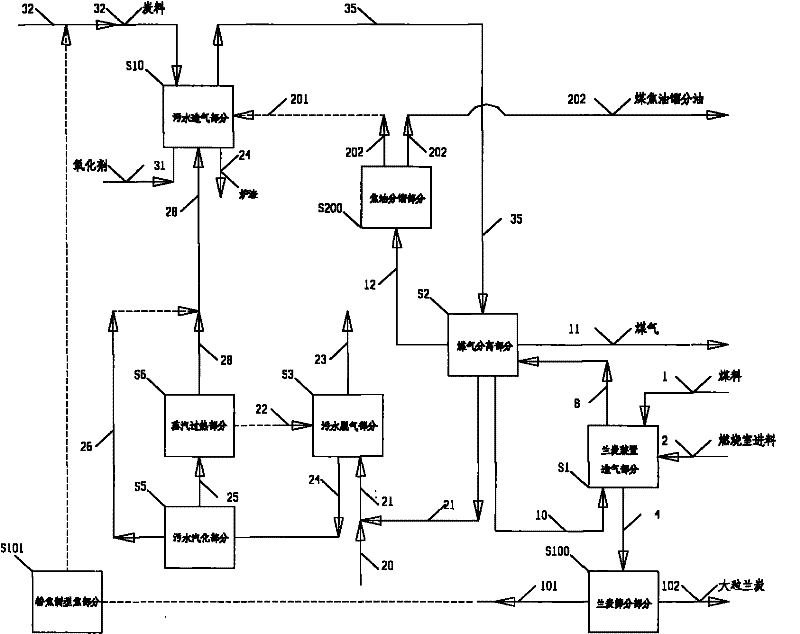

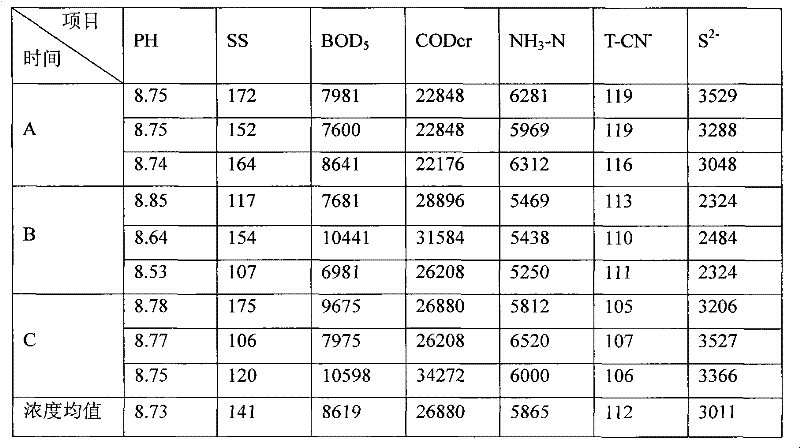

[0219] According to the present invention, the tar-containing sewage is sequentially filtered to remove solid particles, extracted and deoiled, extracted and dephenolized to obtain raw material water F, and then enters the sewage degassing part S3, sewage gasification part S5, steam superheating, etc. Part S6, Sewage gas making part S10, Sewage gas making part S10 produces coal gas 2G. After the boiler generates steam to cool down, after two-stage cooling, pressurization, electric tar capture and other steps, it is finally sent to the semi-coke carbonization furnace. After the tar is captured by electricity, the raw gas is mixed into the joint utilization step, and the purpose of transforming the water component into gas is realized. The process of this embodiment is attached figure 2 shown, but excluding the coal tar pitch coking conversion part, the operating conditions of each step are shown in Table 15.

[0220] The cooling and separation process of flue gas 2G is a wate...

Embodiment 2

[0228] Based on the second embodiment, the waste water recovery gas-making furnace in this example uses hot charcoal from the blue charcoal carbonization furnace.

Embodiment 3

[0230] Based on Example 3, the wastewater recovery gas-making furnace in this example uses hot charcoal from the carbonization furnace for semi-coke production. There is a feeding channel and a feeding carbon lock device between the wastewater gas-making furnace and the carbonization chamber of the semi-coke furnace, and the feeding channel is connected to the semi-coke furnace. The carbon cooling section of the carbonization chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com