Method for preparing 4,4'-dihydroxydiphenylmethane

A technology of dihydroxydiphenylmethane and organic solvents, which is applied in the field of preparation of 4,4'-dihydroxydiphenylmethane, can solve the problems of cumbersome separation and purification, and achieve low production cost, cost reduction and simple purification process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

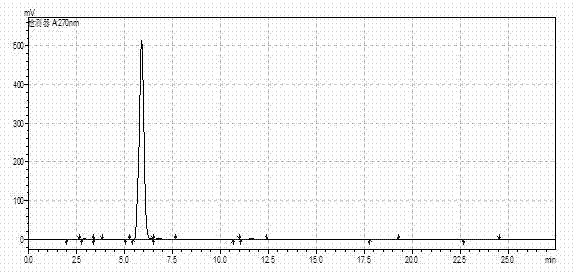

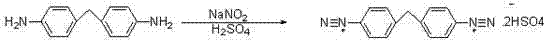

[0028] ①Add 140g of water and 180g of concentrated sulfuric acid (mass concentration 98%) into a 500mL reaction bottle to make a sulfuric acid solution with a mass concentration of 56%, then add 39.6g of MDA, and raise the temperature to 50°C to dissolve all MDA solids. Then cool to 5°C and continue to stir for 0.5h, then slowly add 29.0 g of sodium nitrite, and keep it warm at 5°C until the starch-potassium iodide test paper just turns blue as the end point of the reaction, and a light yellow hydrogen sulfate diazonium salt solution is obtained.

[0029] ②Add 120g of toluene and 20g of copper nitrate into a 1000mL reaction flask, stir and heat to about 70°C, then add dropwise the hydrogen sulfate diazonium salt solution obtained in step ① into the 1000mL reaction flask, and keep the temperature of the solution in the reaction flask during the dropping process At 70~80°C, continue to react for 2 hours after the dropwise addition is completed. The water phase was separated, and...

Embodiment 2

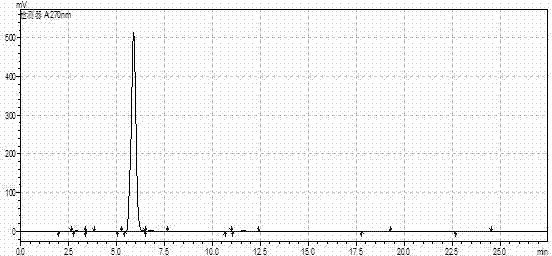

[0039]① Add 100g of water and 180g of concentrated sulfuric acid (mass concentration 98%) to a 500mL reaction bottle to prepare a sulfuric acid solution, then add 39.6g of MDA, heat up to 55°C to dissolve all the solids; then cool to -10°C, and continue to stir for 0.5 h, then slowly add 29.0 g of sodium nitrite, and keep warm at -10°C until the starch-potassium iodide test paper just turns blue as the end point of the reaction to obtain a light yellow hydrogen sulfate diazonium salt solution.

[0040] ② Add 100g of water and 20g of zinc sulfate to a 1000mL reaction bottle, stir and heat to about 90°C, then add the above-mentioned hydrogen sulfate diazonium salt solution dropwise, keep the temperature of the aqueous solution in the reaction bottle at 85~95°C during the dropwise addition, add dropwise After completion, continue to react for 2 hours; then extract twice with 150g chloroform, separate the water phase, wash the organic phase with water to weak acidity (pH=5~7), then...

Embodiment 3

[0044] ① Add 150g of water and 100g of concentrated sulfuric acid (mass concentration 98%) to a 500mL reaction bottle to make a sulfuric acid solution, then add 39.6g of MDA, heat up to 60°C to dissolve all the solids; then cool to 10°C, continue stirring for 0.5h, Then slowly add 29.0 grams of sodium nitrite, keep warm and react until the starch-potassium iodide test paper just turns blue as the reaction end point to obtain light yellow hydrogen sulfate diazonium salt solution.

[0045] ②Add 120g of 2-pentanone and 30g of alumina into a 1000mL reaction flask, stir and heat to about 50°C, add dropwise the hydrogen sulfate diazonium salt solution obtained in step ①, and keep the temperature of the solution in the reaction flask at 40~ 50°C, after the dropwise addition was completed, the reaction was continued for 2h. Separate the water phase, wash the oil phase with water to weak acidity (pH=6~7), and recover 2-pentanone by distillation under reduced pressure. The residue is cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com