Gene engineering antibacterial peptide and preparation method and application thereof

A technology of genetic engineering and antimicrobial peptide, applied in the field of genetic engineering antimicrobial peptide and its preparation, can solve problems such as insufficient antibacterial ability, insufficient antibacterial spectrum, complex structure, etc., achieve strong antibacterial ability, wide antibacterial spectrum, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

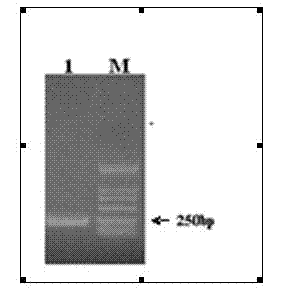

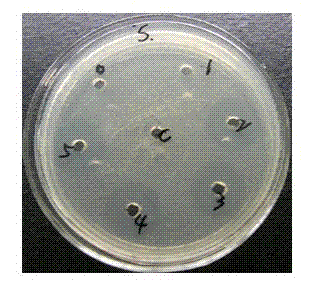

Image

Examples

Embodiment 1

[0034] Preparation method of novel antimicrobial peptide

[0035] 1) Design and synthesis of novel antimicrobial peptide genes

[0036] According to the amino acid sequences of Cecropin A and Magainin II in GenBank, the N-terminus of the cecropin A part, that is, the hybrid peptide, has not been changed in any way, and the natural a-helix structure of the original cecropin A has been maintained. Cecropin A was selected in the hinge region. The hinge region AGP serves as the amino acid composition of the variable region. And replace the non-polar amino acid alanine A near the C terminal of Magainin N terminal with positively charged polar amino acid lysine K, so as not to affect its a-helical structure, enhance the number of positive charges at the C terminal, and make the antibacterial Peptides are more easily and more firmly adsorbed on the surface of bacterial cell membranes. At the same time, in order to ensure the amidation of the C-terminus of the antimicrobial peptide,...

Embodiment 2

[0049] 10L-scale fermenter production and formulation preparation of new antimicrobial peptides

[0050] 1) Antimicrobial peptides After activation, the positive recombinants obtained by screening were inoculated in the Erlenmeyer flask at 1%-10% inoculum, cultured at 28-30°C, 200r / min shaker for 16-24h, and then inoculated with 5%-20% inoculum Put into a 10L fermenter (6L loaded medium), temperature 28-30°C, rotation speed 500-1500r / min, medium pH 5.0-6.0, aeration 0.1-1.0VVM (the amount of oxygen introduced into 1L fermentation broth for 1min) Fermentation was carried out under the condition of dissolved oxygen>20%. After 18-24 hours of cultivation, 50% glycerol was added for 4 hours. When the dissolved oxygen suddenly rose to 100%, methanol was added until the end of fermentation. The whole fermentation lasted for 48-72 hours.

[0051] 2) After the fermentation, the original tank was steam sterilized at 100°C for 10-20 minutes, discharged, centrifuged at 5000r / min for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com