Antistatic compound and antistatic film containing same

An anti-static and composition technology, applied in conductive coatings, coatings, layered products, etc., can solve the problems of poor placement stability, large fluctuations, low efficiency, etc., and achieve stable anti-static performance and uniform anti-static coating. , to ensure the effect of optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Configuration of antistatic composition:

[0037] Nano tin oxide polyester latex (particle size 0.2nm) 80g;

[0038] Polyurethane-acrylate composite emulsion 5g;

[0039] Deionized water 200g;

[0040] Sodium dodecylbenzenesulfinate 0.1g;

[0041] According to the above proportions, the materials are added into a mixing container and stirred evenly to obtain an antistatic composition, which is ready for use.

[0042] Preparation of antistatic film:

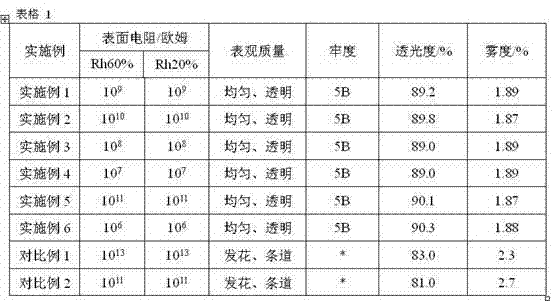

[0043] The above-mentioned antistatic composition was coated on the surface of a 100-micron polyester film by roll coating, and heated and dried at a temperature of 90° C. for 2 minutes to obtain an anti-static polyester film with an anti-static layer thickness of 0.01 micron. Its performance can be seen in Table 1.

Embodiment 2

[0045] Configuration of antistatic composition:

[0046] Nano-doped indium tin oxide polyester latex (particle size 80nm) 100g;

[0047] Polyurethane-acrylate composite emulsion 8g;

[0048] 300g deionized water;

[0049] 20g of isopropanol;

[0050] Aqueous silane compound 0.7g;

[0051] According to the above proportions, the materials are added into a mixing container and stirred evenly to obtain an antistatic composition, which is ready for use.

[0052] Preparation of antistatic film:

[0053] The above composition was coated on the surface of a 100-micron polyester film by a roll coating method, and heated and dried at a temperature of 100° C. for 1 minute to obtain an anti-static polyester film with an anti-static layer thickness of 2 microns. Its performance can be seen in Table 1.

Embodiment 3

[0055] Configuration of antistatic composition:

[0056] Nano zinc oxide polyester latex (120nm) 120g;

[0057] Polyurethane-acrylate composite emulsion 12g;

[0058] 400g deionized water;

[0059] Ethanol 50g;

[0060] Sodium dodecylbenzenesulfinate 1.2g;

[0061] According to the above proportions, the materials are added into a mixing container and stirred evenly to obtain an antistatic composition, which is ready for use.

[0062] Preparation of antistatic film:

[0063] The above composition was coated on the surface of a 100-micron polyester film by a roll coating method, and heated and dried at a temperature of 110° C. for 1 minute to obtain an anti-static polyester film with an anti-static layer thickness of 5 microns. Its performance can be seen in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com