Method for growing ZnO-TCO thin film with suede structure and application

A technology of suede and film, which is applied in the field of growing ZnO-TCO film with a suede structure, can solve the problems of poor performance of ZnO film, small suede structure, poor optical transmittance, etc. The effect of improving and good electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

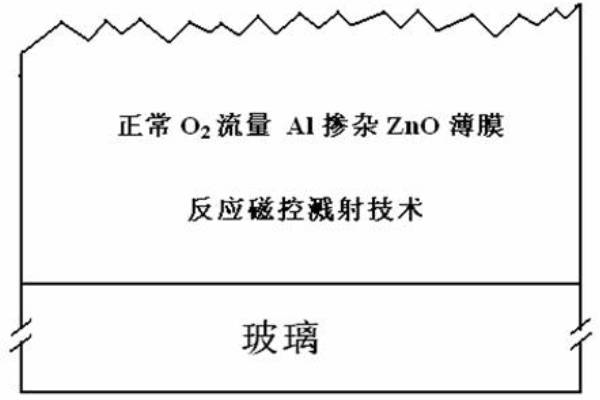

[0027] 1. Using magnetron sputtering technology, with the help of high-purity Zn-Al alloy target (component purity: 99.99%, wherein the weight percentage content of the dopant Al component is 2.0%) and O 2 As the raw material, the sputtering gas is Ar gas, and the textured ZnO thin film is directly grown on the glass substrate at low temperature. The substrate temperature is 250°C, and the background vacuum is 8×10 -5 Pa, the sputtering pressure is 4.5mTorr, and the sputtering power density is 1.0W / cm 2 , the thickness of the film is 1500nm, and the film structure obtained by growth is: glass / gradient oxygen flow rate is "moderate flow rate + normal flow rate" and the texture structure Al-doped ZnO film is grown under the condition of "moderate flow rate + normal flow rate". The total number of coating times is 25 cycles, of which the moderate An oxygen flow rate of 12 sccm is 10 cycles, and a normal oxygen flow rate of 9.0 sccm is 15 cycles. Its roughness RMS~70nm. figure...

Embodiment 2

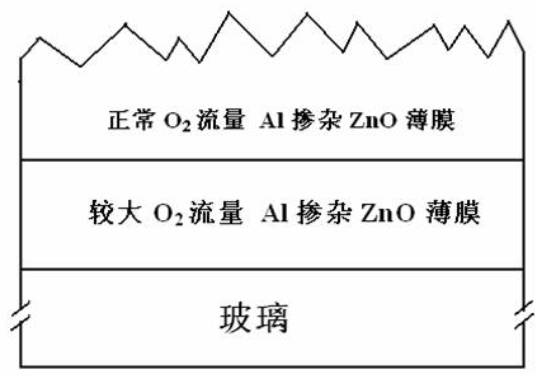

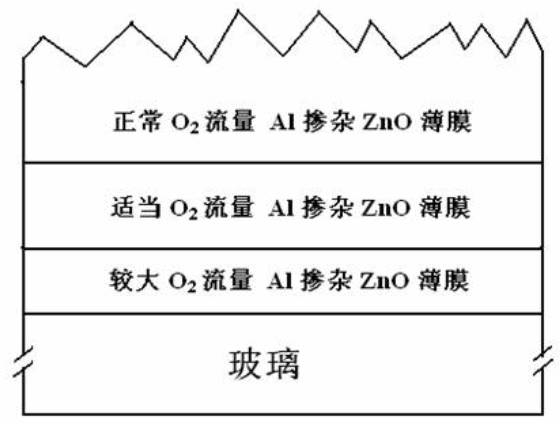

[0030] 1. Using magnetron sputtering technology, with the help of high-purity Zn-Al alloy target (component purity: 99.99%, in which the weight percentage content of the dopant Al component is 1.0%) and O 2 As the raw material, the sputtering gas is Ar gas, and the textured ZnO thin film is directly grown on the glass substrate at low temperature. The substrate temperature is 300°C, and the background vacuum is 8×10 -5 Pa, the sputtering pressure is 4.3mTorr, and the sputtering power density is 0.92W / cm 2 , the thickness of the film is 1500nm, and the film structure obtained by growth is: glass / gradient oxygen flow rate is "large flow rate + moderate flow rate + normal flow rate" and the texture structure Al-doped ZnO film is grown under the condition of 25 coating times in total. Cycle, where the maximum oxygen flow rate of 20 sccm is 5 cycles, the moderate oxygen flow rate of 12 sccm is 10 cycles, and the normal oxygen flow rate of 9.0 sccm is 10 cycles. Its roughness RMS~...

Embodiment 3

[0033] 1. Using magnetron sputtering technology, with the help of high-purity Zn-Al alloy target (component purity: 99.99%, in which the weight percentage content of the dopant Al component is 0.5%) and O 2 As the raw material, the sputtering gas is Ar gas, and the textured ZnO thin film is directly grown on the glass substrate at low temperature. The substrate temperature is 300°C, and the background vacuum is 8×10 -5 Pa, the sputtering pressure is 4.0mTorr, and the sputtering power density is 1.0W / cm 2 , the thickness of the film is 1500nm, and the film structure obtained by growth is: glass / gradient oxygen flow rate is "large flow rate + moderate flow rate + normal flow rate" and the texture structure Al-doped ZnO film is grown under the condition of 25 coating times in total. Cycles, where the maximum oxygen flow rate of 20 sccm is 5 cycles, the moderate oxygen flow rate of 12 sccm is 8 cycles, and the normal oxygen flow rate of 9.0 sccm is 12 cycles. Its roughness RMS~7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com