Colored photosensitive resin composition, color filter and image display device

A technology of photosensitive resin and composition, applied in the directions of instruments, optics, filters, etc., can solve the problems of insufficient curing degree, decreased transmittance, pattern peeling, etc., and achieve excellent transmittance and excellent storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

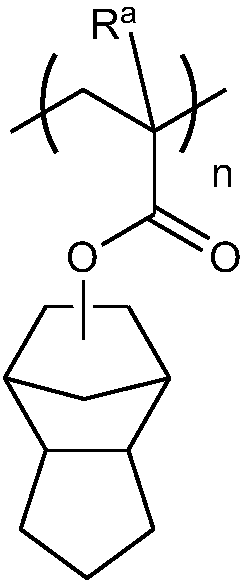

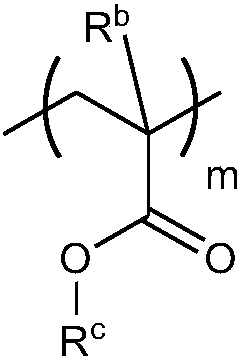

Method used

Image

Examples

Synthetic example 1

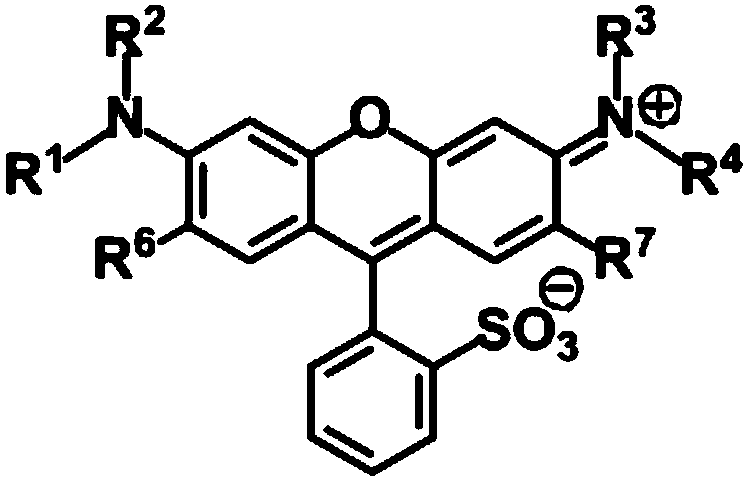

[0194] Synthesis Example 1: Synthesis of Xanthene Compounds

[0195] Step 1: Synthesis of the compound represented by the chemical formula (Aa-33-IM)

[0196]

[0197] In a flask equipped with a condenser tube and a stirring device, add 1 part by weight of the compound represented by the above chemical formula (X) (manufactured by Zhongwai Huacheng), 7 parts by weight of N-methylpyrrolidone, 1.0 parts by weight of potassium carbonate and 4-bromobutyric acid 2.0 parts by weight of ethyl ester was stirred at 100° C. for 7.5 hours. After standing to cool, 20 parts by weight of 2N hydrochloric acid was added to the obtained reaction liquid, extracted twice with 45 parts by weight of chloroform, the chloroform layers were stacked together, washed with saturated brine, and dried over anhydrous magnesium sulfate. The solvent was distilled off under reduced pressure and dried under reduced pressure at 60° C. to obtain 4.1 parts by weight of a crude compound represented by the che...

Synthetic example 2

[0208] Synthesis Example 2: Synthesis of Xanthene Compounds

[0209] Step 1: Synthesis of the compound represented by the chemical formula (Aa-41-IM)

[0210]

[0211] In a flask equipped with a condenser tube and a stirring device, add 5 parts by weight of 3,6-dichlorosulfone fluorescein (manufactured by Zhongwaihuacheng) represented by the above chemical formula (XX), 35 parts by weight of N-methylpyrrolidone and 3-amino - 12.2 parts by weight of methyl 4-methylbenzoate, stirred at 130°C for 7 hours. After standing to cool, the obtained reaction liquid was added to an aqueous solution of 7.5 parts by weight of concentrated hydrochloric acid and 70 parts by weight of ion-exchanged water, and stirred at room temperature for 30 minutes to obtain crystals. The crystals were classified by filtration, sufficiently washed with ion-exchanged water, and dried under reduced pressure at 60° C. to obtain 6.6 parts by weight of a compound represented by the following chemical formu...

manufacture example 1

[0228] Production Example 1: Production of Pigment Dispersion Liquid M1

[0229] 10.0 parts by weight of C.I. Pigment Blue 15:6 as a pigment, 5.0 parts by weight of LPN-6919 (manufactured by BYK) as a pigment dispersant, and 20 parts by weight of 4-hydroxyl-4- Methyl-2-pentanone and 65.0 parts by weight of propylene glycol monomethyl ether acetate were mixed and dispersed with a bead mill for 12 hours to prepare pigment dispersion liquid M1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Solid content acid value | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com