High-frequency thyristor

A thyristor, high-frequency technology, applied in the direction of thyristor, electrical components, circuits, etc., can solve the problems of reducing application frequency and sacrificing efficiency, and achieve the effect of increasing the recombination center, large cathode area, and ensuring withstand voltage and dynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

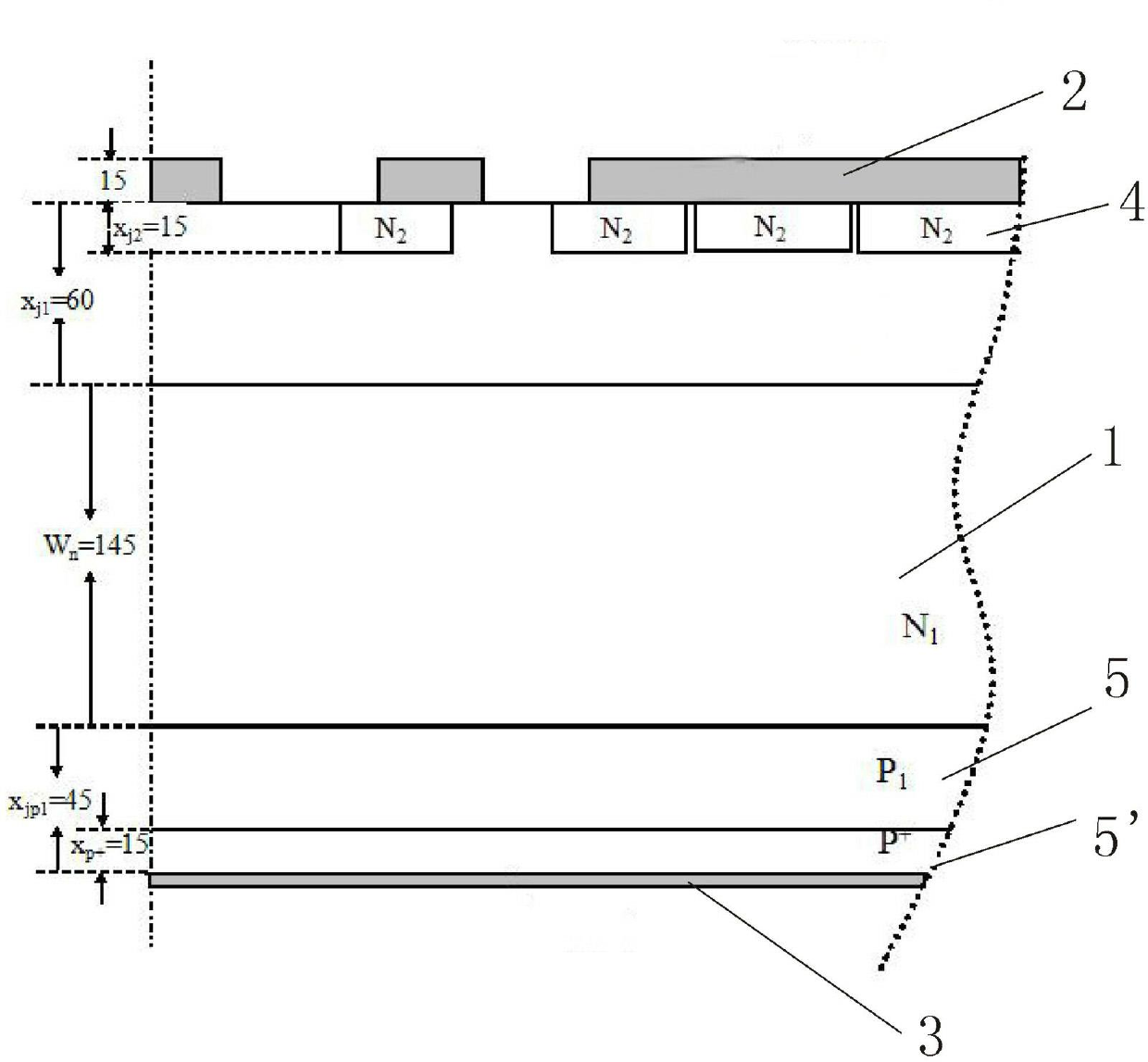

[0059] The high-frequency thyristor of the present invention is double-sided on the N-type (100) crystal orientation, low-resistance (40~50) Ω medium-irradiated single-crystal silicon wafer 1, and the P layer 5, 5' is double-sided and once vacuum closed tube diffused, that is, once P-type pure gallium diffusion, junction depth 55μm, single-side grinding 15μm after expansion P + Layer 5' is used as the anode side, oxidized and photolithographically etched on the other P-type side, and then phosphorous oxychloride N + Diffuse to form N 2 Zone 4, constituting an asymmetric thyristor P with a total thickness of 250 μm + P 1 N 1 P 2 N 2 basic structure, such as figure 1 shown;

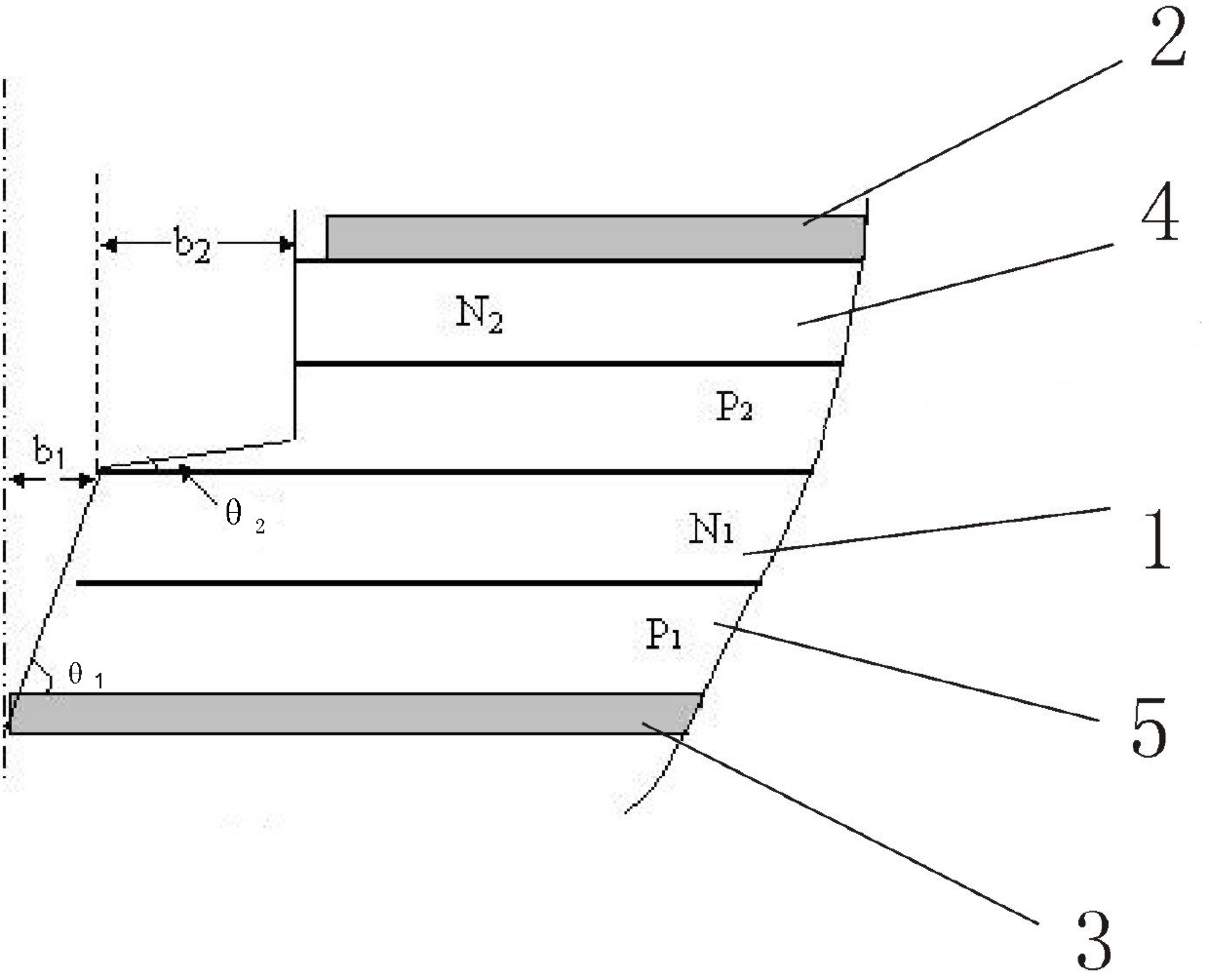

[0060] The shape of the table is changed from grinding angle shape to sandblasting shape, which is positive and negative angle structure. That is, the positive bevel is large-angle sandblasting, and the situation that the grinding angle can only be less than 35 degrees can be changed, and the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com