Coagulation-oxidation combined type method for processing sewage

A sewage treatment method and combined technology, which are applied in the directions of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the complicated operation process, limited flocculation effect, investment and operation cost Increase and other problems, to achieve the effect of good effluent quality, small footprint, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

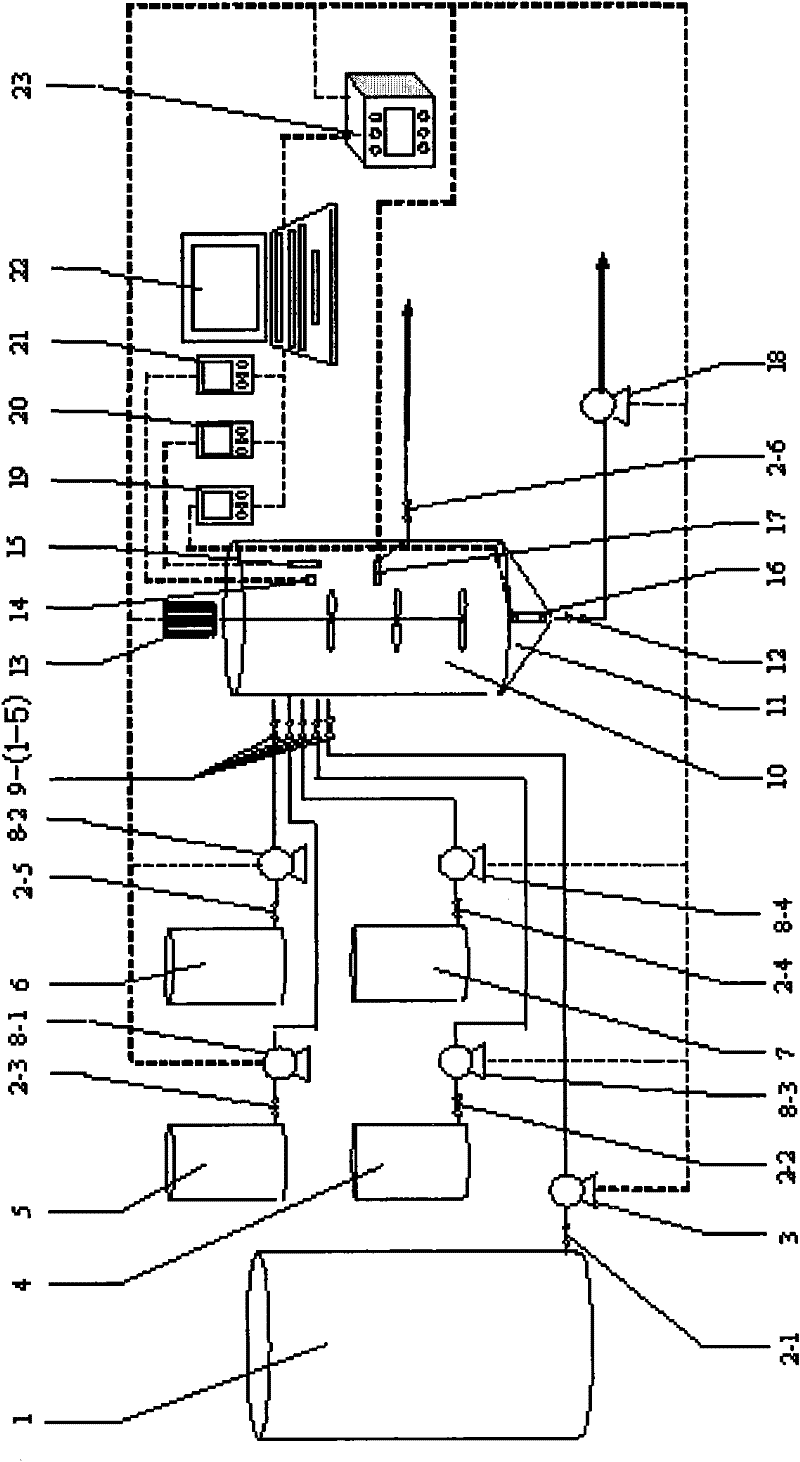

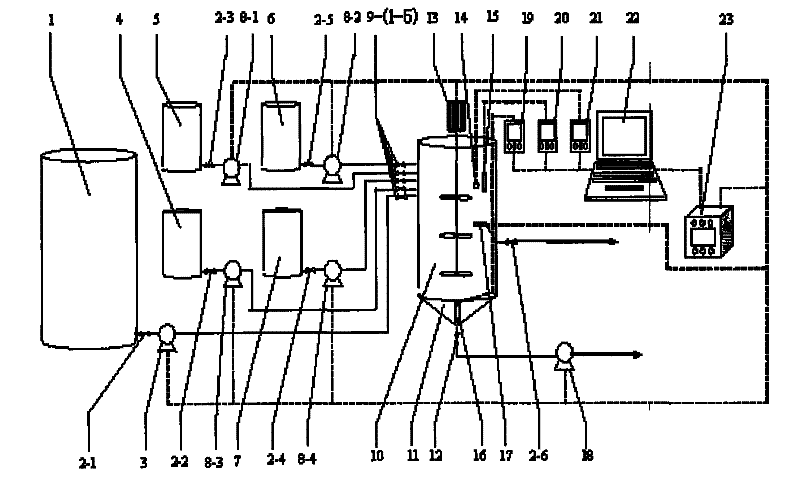

Image

Examples

Embodiment 1

[0031] The coagulation-Fenton combined treatment is carried out on the secondary treatment effluent of an oil refinery sewage treatment plant by using the technology of the present invention. The COD concentration of the raw water is 92.7mg / L, the ammonia nitrogen concentration is 5.3mg / L, and the petroleum is 3.6mg / L. Set each operation cycle as 360min, which is divided into the following nine processes:

[0032] (1) Water intake: open the reaction tank feed valve 9-5, the adjustment tank discharge valve 2-5, the water inlet pump 3 and the variable speed mixer 13, and the water to be treated in the adjustment tank 1 enters the reaction tank 10, which is the same as the last operation The solid precipitation remaining in the period (or the coagulant manually added during the first operation) is uniformly mixed, and the water level is set by the process controller 23 to be 2 / 3 of the height of the reaction tank 10, the pH value is 4.0, and the feeding pump 8- 1. Feed valve 9-1,...

Embodiment 2

[0043] After biochemical treatment of wastewater discharged from a chemical plant, the concentration of COD is 306.9mg / L, BOD 5 It is 18.6mg / L, B / C=0.06, which belongs to typical refractory sewage. Adopt the technology of the present invention to carry out coagulation-Fenton combined treatment to it, set each operating cycle as 360min, be divided into the following eight operations (no secondary mud discharge, that is, the dosage of coagulant is Fenton oxidation 100% of the solid precipitated from the process):

[0044] (1) Water intake: open the reaction tank feed valve 9-5, the adjustment tank discharge valve 2-5, the water inlet pump 3 and the variable speed mixer 13, and the water to be treated in the adjustment tank 1 enters the reaction tank 10, which is the same as the last operation The solid precipitation remaining in the period (or the coagulant manually added during the first operation) is evenly mixed, and the water level is set by the process controller 23 to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com