Water-soluble polymer dispersion liquid, paper strength agent, papermaking filter aid and papermaking retention agent

A technology of water-soluble polymers and dispersions, applied in the direction of adding retention aids, reinforcing agents, etc., can solve problems such as deterioration, drainage, difficulty in improving retention, and increased concentration, and achieve the effect of improving drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0049] (Manufacturing example 1) Manufacturing method of polymer dispersant

[0050]In a 2-liter five-necked liquid separator (separable flask) with a stirrer, a thermometer, a reflux cooling tube, and a nitrogen gas introduction tube, 250 g of an 80% by weight aqueous solution of acryloyloxyethyltrimethylammonium chloride (pure compound weight of 200g), 529g of ion-exchanged water, heated to 65°C and replaced with nitrogen. 20 g of a 5% by weight aqueous solution of 2,2'-azobis(2-amidinopropane) hydrochloride was added thereto as a polymerization initiator, and polymerization was performed with stirring. The temperature was raised by self-heating, and the polymerization reaction was performed at 80° C. for 1 hour to obtain a polymer dispersant.

[0051] After adjusting the non-volatile content to 20% by weight, the temperature was adjusted to 25° C., and the viscosity of the obtained polymer dispersant was measured using a Vismetron viscometer (manufactured by Shibaura Syste...

manufacture example 2

[0052] (Manufacturing example 2) Manufacturing method of polymer dispersant

[0053] In a five-necked separatory flask of 2 liters with a stirrer, a thermometer, a reflux cooling pipe, and a nitrogen inlet pipe, add 249.99 g of an 80% by weight aqueous solution of acryloyloxyethyltrimethylammonium chloride (the weight of the pure compound is 199.992 g) g; 99.995 mol %), 0.008 g (0.005 mol %) of methylenebisacrylamide, 529.7 g of ion-exchanged water, heated to 50° C. and replaced with nitrogen. 20 g of a 1.5% by weight aqueous solution of 2,2'-azobis(2-amidinopropane) hydrochloride was added thereto as a polymerization initiator, and polymerized with stirring. The temperature was raised by self-heating, and the polymerization reaction was performed at 80° C. for 1 hour to obtain a polymer dispersant.

manufacture example 3

[0054] (Manufacturing example 3) Manufacturing method of polymer dispersant

[0055] In a five-necked separatory flask of 2 liters with a stirrer, a thermometer, a reflux cooling pipe, and a nitrogen inlet pipe, add 215.63 g of an 80% by weight aqueous solution of acryloyloxyethyltrimethylammonium chloride (the weight of the pure compound is 172.5 g) g; 69.85 mole %), 0.1966 g (0.1 mole %) methylenebisacrylamide, 0.1 g (0.05 mole %) sodium methallyl sulfonate, 27.2 g (30 mole %) acrylamide, 536.47 g ion Exchange water, heat to 60°C and replace with nitrogen. 20 g of a 2 wt % aqueous solution of 2,2'-azobis(2-amidinopropane) hydrochloride was added thereto as a polymerization initiator, and the mixture was polymerized with stirring. The temperature was raised by self-heating, and the polymerization reaction was performed at 80° C. for 1 hour to obtain a polymer dispersant.

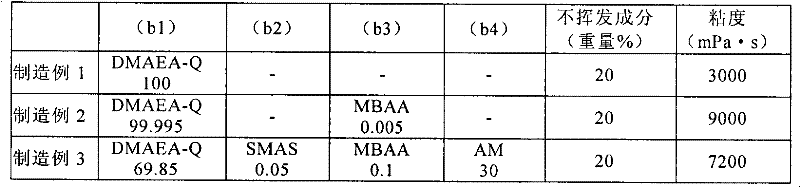

[0056] Table 1

[0057]

[0058] In the table, the numbers of (b1)-(b4) are mole %, the viscosity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com