Apparatus and cultivating method for scaled cultivation of microalgae

A large-scale, microalgae technology, applied in the direction of microorganism-based methods, stress-stimulated microbial growth methods, enzymatic/microbiological devices, etc., can solve the limitations of large-scale applications, limited number of reactors, reactor investment and operating costs Problems such as high cost, to achieve the effect of increasing cell production speed, solving efficiency/cost, and reducing temperature control cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

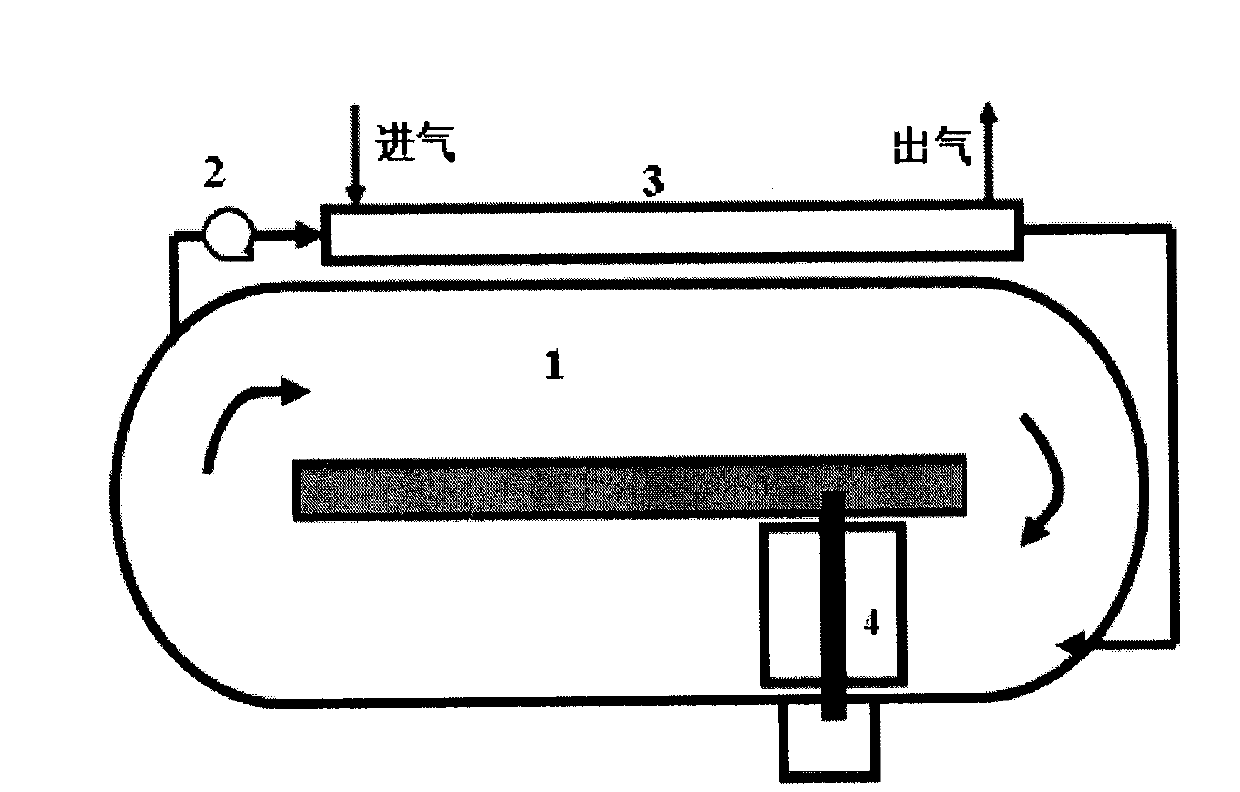

[0039] Two elliptical track pools with a length of 3.8 meters and a width of 1.9 meters are used for outdoor cultivation of Nanochoropsis. Its filling height is 0.25 meters (1500 liters of filling volume), and the stirring water velocity is 0.25 meters per second. Nitrogen-enriched f / 2 medium (NaNO 3 Concentration 0.75 g / L), cell seeding density 0.1 g / L. One of the runway pools is connected with a flat-plate photoreactor prepared by a plexiglass plate with a liquid capacity of 0.05 meters, a height of 1.2 meters, and a width of 2.4 meters by a water pump. The culture solution on one side of the open pool is pumped from the bottom of one side of the flat photoreactor, and then flows back to the other side of the open pool from the upper part of the other side of the flat photoreactor, and the flow rate of the water pump is controlled to 1000 liters / hours to keep the average residence time of the culture medium in the flat photobioreactor at 45 seconds. Flat-plate photoreact...

Embodiment 2

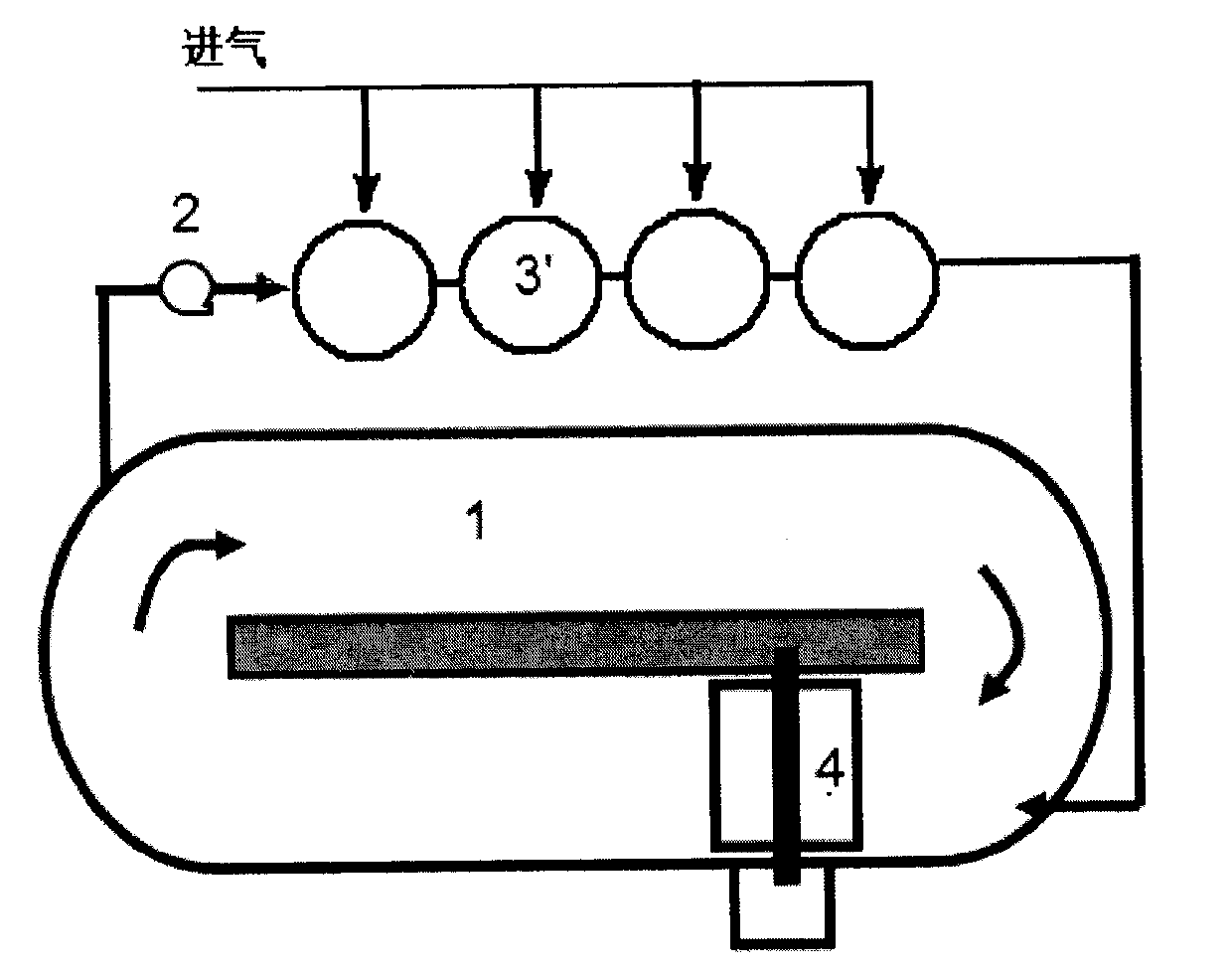

[0041]Two elliptical track pools with a length of 3.8 meters and a width of 1.9 meters are used for outdoor Nanchoropsis cultivation. Its filling height is 0.25 meters (1500 liters of filling volume), and the stirring water velocity is 0.25 meters per second. Nitrogen-enriched f / 2 medium (NaNO 3 Concentration 0.75 g / L), cell seeding density 0.1 g / L. One of the runway pools is connected with two flat photoreactors with a thickness of 0.05 meters, a height of 1.2 meters, a width of 2.4 meters, and a plexiglass plate with a liquid capacity of 125 liters. The culture solution on one side of the open pool is pumped from the bottom of one side of the flat photoreactor, and then flows back to the other side of the open pool from the upper part of the other side of the flat photoreactor, and the flow rate of the water pump is controlled to 1500 liters / hours to keep the average residence time of the culture medium in the flat photobioreactor at 30 seconds. Flat-plate photoreactor i...

Embodiment 3

[0043] Two elliptical track pools with a length of 3.8 meters and a width of 1.9 meters are used for outdoor chlorella cultivation. Its filling height is 0.25 meters (1500 liters of filling volume), and the stirring water velocity is 0.25 meters per second. Nitrogen-enriched f / 2 medium (NaNO 3 Concentration 0.75 g / L), cell seeding density 0.15 g / L. One of the runway pools passes through a water pump with a flow rate of 1000 liters / hour, and then branches into 6 bubble column photoreactors with a diameter of 160 mm and a height of 1.8 meters (the liquid volume of each bubble column reactor is 30 liters) , the culture solution returns to the runway pool, and the average residence time of the culture solution in each bubble column photoreactor is 11 seconds. Bubble column photoreactor fed with air / CO 2 Mixed gas (5% CO 2 , v / v), the ventilation volume is 0.3VVM. During the cultivation period, the average temperature and light intensity are: 15°C at 8:00, 950umol / m 2 / s, 35°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com