Compound feed capable of improving dressing percentage of Tilapia mossambica and preparation method thereof

A technology for compound feed and meat yield, applied in the field of compound feed for tilapia, can solve the problems of not being able to better improve the protein content of tilapia, affecting the nutritional value of tilapia, damaging the health of animals, and achieving good absorption. , scientific proportioning, the effect of improving the meat yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

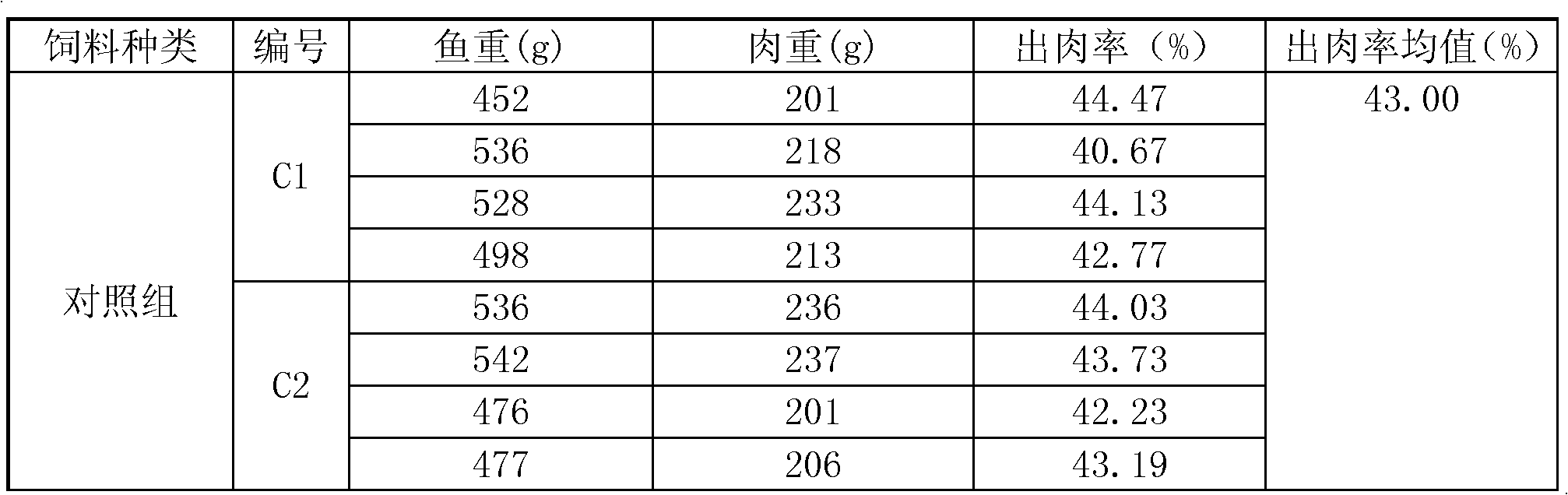

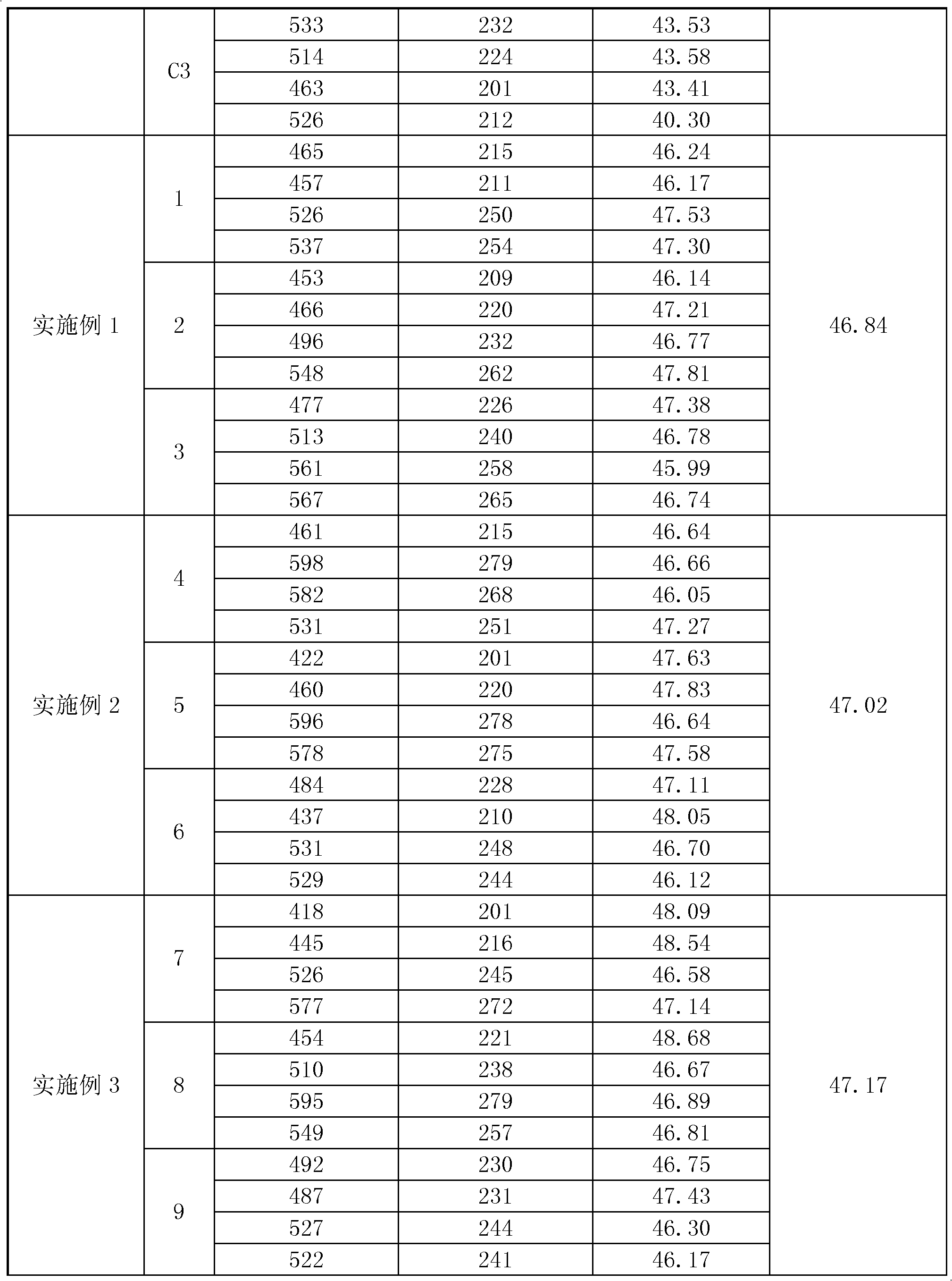

Examples

Embodiment 1

[0024] The weight percentage composition of each raw material component of the compound feed:

[0025] Fermented rapeseed meal 15%, fermented soybean meal 25%, fish meal 7%, wheat 20%, chicken meal 8%, distiller's grains 15%, calcium dihydrogen phosphate 2%, fish oil 4%, vitamin premix 2%, mineral premix Blend 2%.

[0026] Wherein, the mineral premix contains 12g of ferric citrate, 25g of zinc sulfate heptahydrate, 10g of potassium iodate, 20g of manganese sulfate monohydrate, 3g of potassium chloride, 40g of copper sulfate pentahydrate, 40g of copper sulfate pentahydrate, and Sodium 15g, manganese sulfate heptahydrate 0.5g, zeolite powder balance.

[0027] Preparation steps of compound feed:

[0028] 1) Weigh each raw material component and mix evenly.

[0029] 2) pulverize the mixed raw material components described in step 1) using an ultrafine pulverizer until all components can pass through a 350 μm sieve;

[0030] 3) Move the pulverized components described in step 2...

Embodiment 2

[0034] The weight percentage composition of each raw material component of the compound feed:

[0035] Fermented rapeseed meal 20%, fermented soybean meal 25%, fish meal 6%, wheat 25%, chicken meal 5%, distiller's grains 10%, calcium dihydrogen phosphate 3%, fish oil 3%, vitamin premix 1%, mineral premix Blend 2%.

[0036] Wherein, the mineral premix contains 12g of ferric citrate, 25g of zinc sulfate heptahydrate, 10g of potassium iodate, 20g of manganese sulfate monohydrate, 3g of potassium chloride, 40g of copper sulfate pentahydrate, 40g of copper sulfate pentahydrate, and Sodium 15g, manganese sulfate heptahydrate 0.5g, zeolite powder balance.

[0037] Preparation steps of compound feed:

[0038] 1) Weigh each raw material component and mix evenly.

[0039] 2) pulverize the mixed raw material components described in step 1) using an ultrafine pulverizer until all components can pass through a 420 μm sieve;

[0040] 3) Move the pulverized components described in step 2...

Embodiment 3

[0044] The weight percentage composition of each raw material component of the compound feed:

[0045] Fermented rapeseed meal 20%, fermented soybean meal 20%, fish meal 5%, wheat 25%, chicken meal 5%, distiller's grains 15%, calcium dihydrogen phosphate 3%, fish oil 4%, vitamin premix 2%, mineral premix Blend 1%.

[0046] Wherein, the mineral premix contains 12g of ferric citrate, 25g of zinc sulfate heptahydrate, 10g of potassium iodate, 20g of manganese sulfate monohydrate, 3g of potassium chloride, 40g of copper sulfate pentahydrate, 40g of copper sulfate pentahydrate, and Sodium 15g, manganese sulfate heptahydrate 0.5g, zeolite powder balance.

[0047] Preparation steps of compound feed:

[0048] 1) Weigh each raw material component and mix evenly.

[0049] 2) pulverize the mixed raw material components described in step 1) using an ultrafine pulverizer until all components can pass through a 400 μm sieve;

[0050] 3) Move the pulverized components described in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com