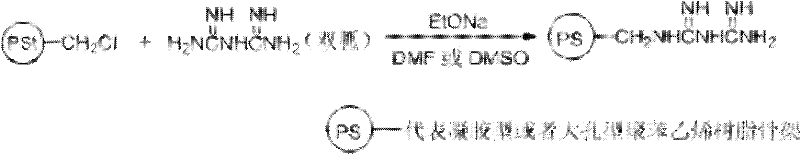

High-temperature-resistant guanidine-based strong-basic anion exchange resin for strong base and synthesis method thereof

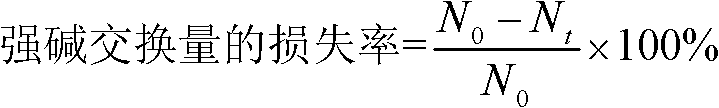

A technology of exchange resin and synthesis method, which is applied in the direction of anion exchange, ion exchange, chemical instruments and methods, etc. It can solve the problems of cumbersome synthesis process, no fundamental improvement of resin thermal stability, expensive synthetic raw materials, etc., and achieve simple synthesis process , The effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]In a 250ml three-necked bottle equipped with mechanical stirring, a spherical condenser, and a thermometer, add 20 g of gel-type chloromethylated polystyrene resin with a crosslinking degree of 1% (w%) (chlorine content is 5.26 mmol / g) and 160mL N,N-dimethylformamide (DMF). After the resin was fully swelled in DMF for 4 hours, 12.5g (ie 211.8 mmol) of guanidine was added to the three-neck flask, stirring was started, and at the same time, the concentration of 3mol / L ethanol After the DMF solution of sodium regulates the alkalescence of reaction solution to pH=10, start to heat up, when to 60 DEG C, after being incubated for 8 hours, sampling, the residual chlorine content in the measuring resin is 0.24mmol / g, stops heating and stirring, Let it stand at room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH value of the washing solution is 7.0, drain the free water of the above resin, and obtain the light yellow spherical...

Embodiment 2

[0037] In a 500ml three-necked flask equipped with mechanical stirring, a spherical condenser, and a thermometer, add 30g of gel-type chloromethylated polystyrene resin with a crosslinking degree of 4% (w%) (chlorine content is 4.98mmol / g) and 240mL N,N-dimethylformamide (DMF). After the resin is fully swelled in DMF for 8 hours, add 22.0g (ie 372.9 mmol) guanidine into the three-necked flask, start stirring, and use a concentration of 3mol / L The DMF solution of sodium ethylate adjusted the alkalinity of the reaction solution to pH=12, then began to heat up, and when it reached 65 ° C, after 12 hours of insulation, sampling was carried out, and the residual chlorine content in the measured resin was 0.28mmol / g, and the heating and stirring were stopped. , let it stand to room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH value of the washing solution is 7.2, drain the free water of the above resin, and obtain the light yel...

Embodiment 3

[0039] In a 1L three-neck flask equipped with mechanical stirring, a spherical condenser, and a thermometer, add 50 g of gel-type chloromethylated polystyrene resin with a crosslinking degree of 2% (w%) (chlorine content is 5.15mmol / g) and 450 mL of dimethyl sulfoxide (DMSO). After the resin was fully swollen in DMSO for 5 hours, 57.2 g (566.3 mmol) of biguanide was added to the three-necked flask, and stirring was started. After the DMSO solution adjusted the alkalinity of the reaction solution to pH=11, it began to heat up, and when it reached 65 ° C, after 10 hours of heat preservation, sampling was carried out, and the residual chlorine content in the resin was determined to be 0.25 mmol / g, and the heating and stirring were stopped, and left to stand To room temperature, filter out the resin, wash the resin with a large amount of deionized water until the pH value of the washing solution is 6.8, drain the free water of the above resin, and obtain the light yellow spherical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com