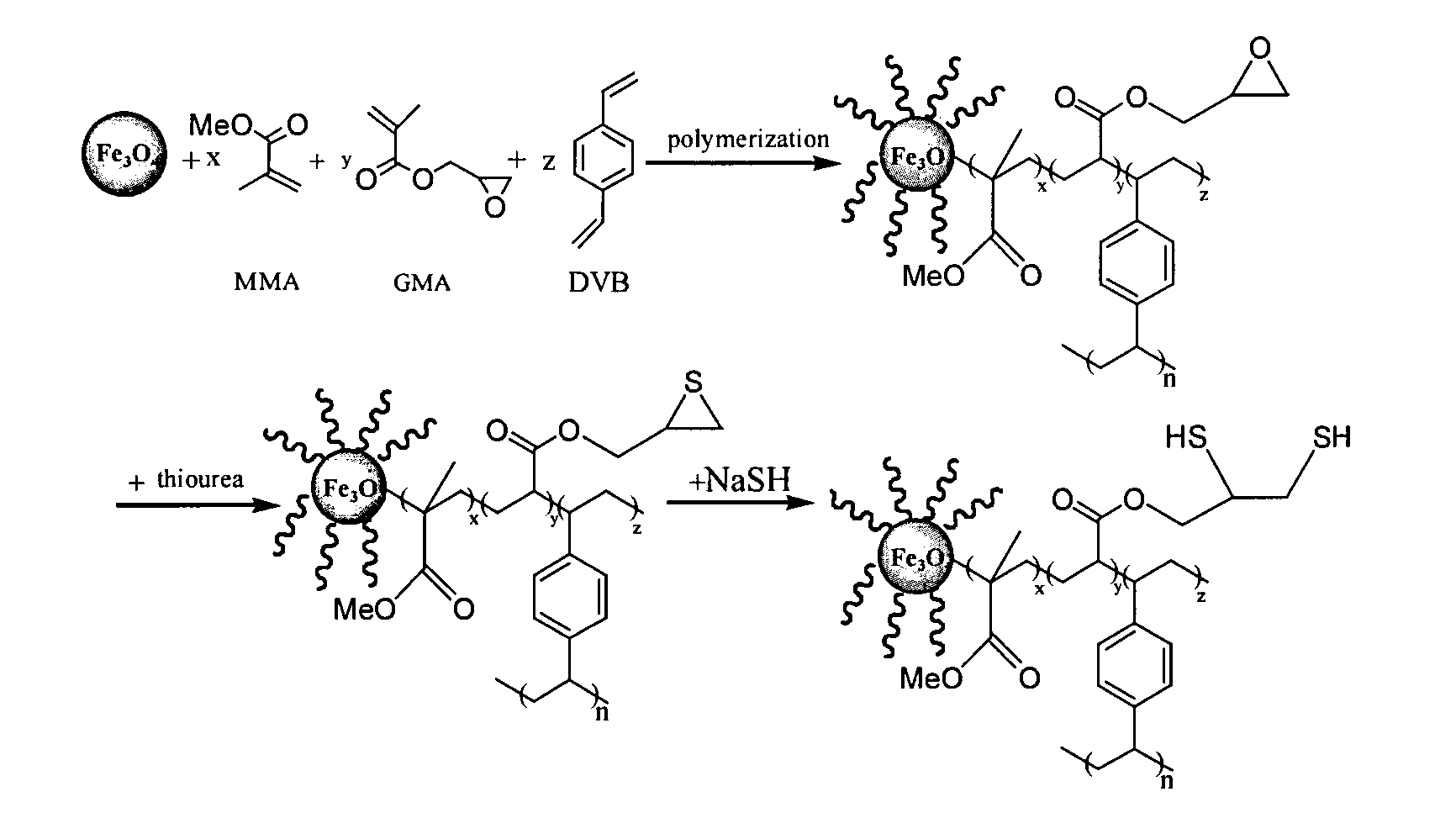

Method for preparing thiolated nano ferroferric oxide magnetic polymer composite material

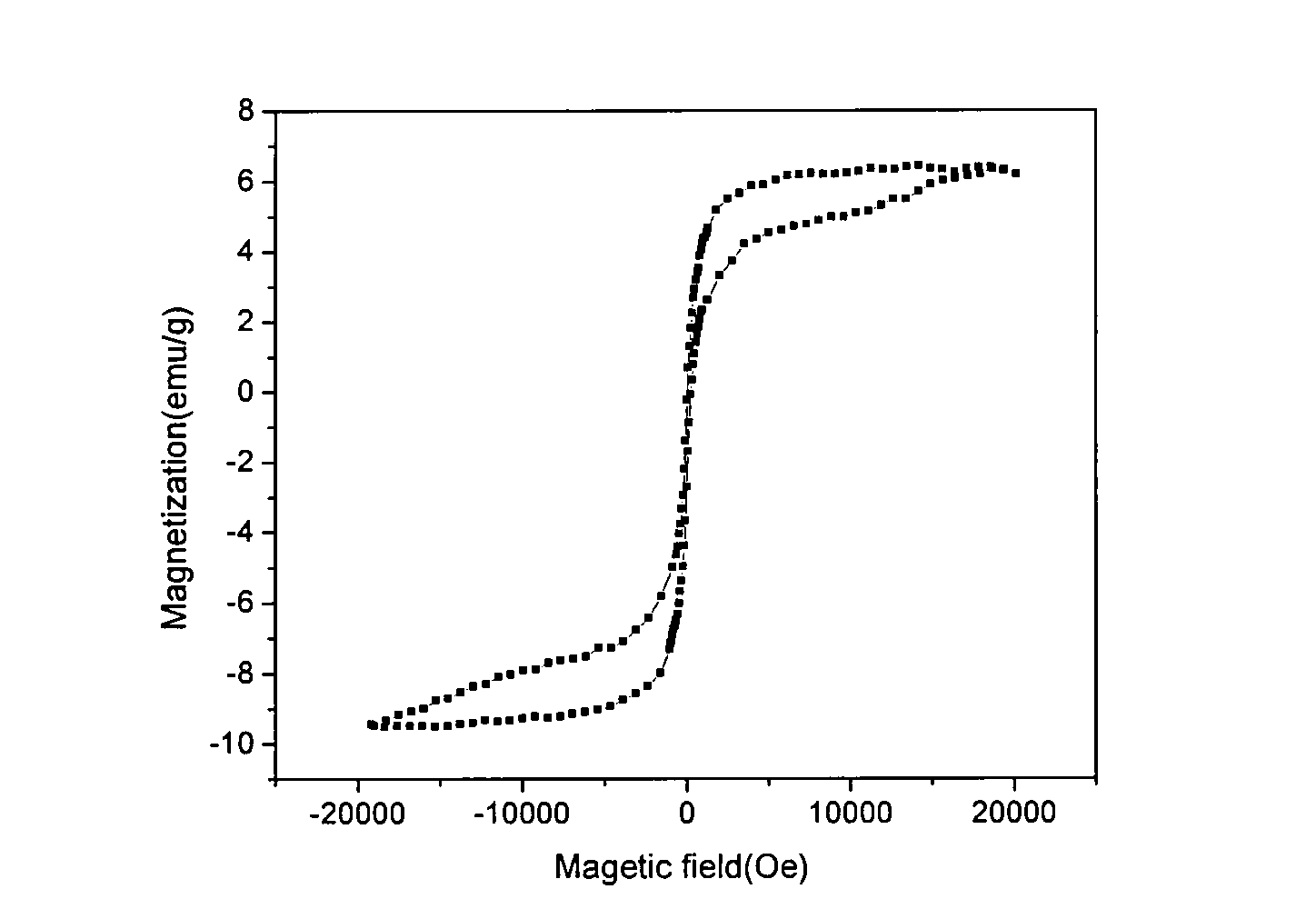

A technology of ferroferric oxide and polymer materials, which is applied in chemical instruments and methods, iron oxide/iron hydroxide, oxides of ferrous iron, etc. It can solve the problems of difficult control of the proportion of functional groups, long reaction cycle, cumbersome operation, etc. problems, to achieve the effects of controllable magnetic content, shortened reaction cycle, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

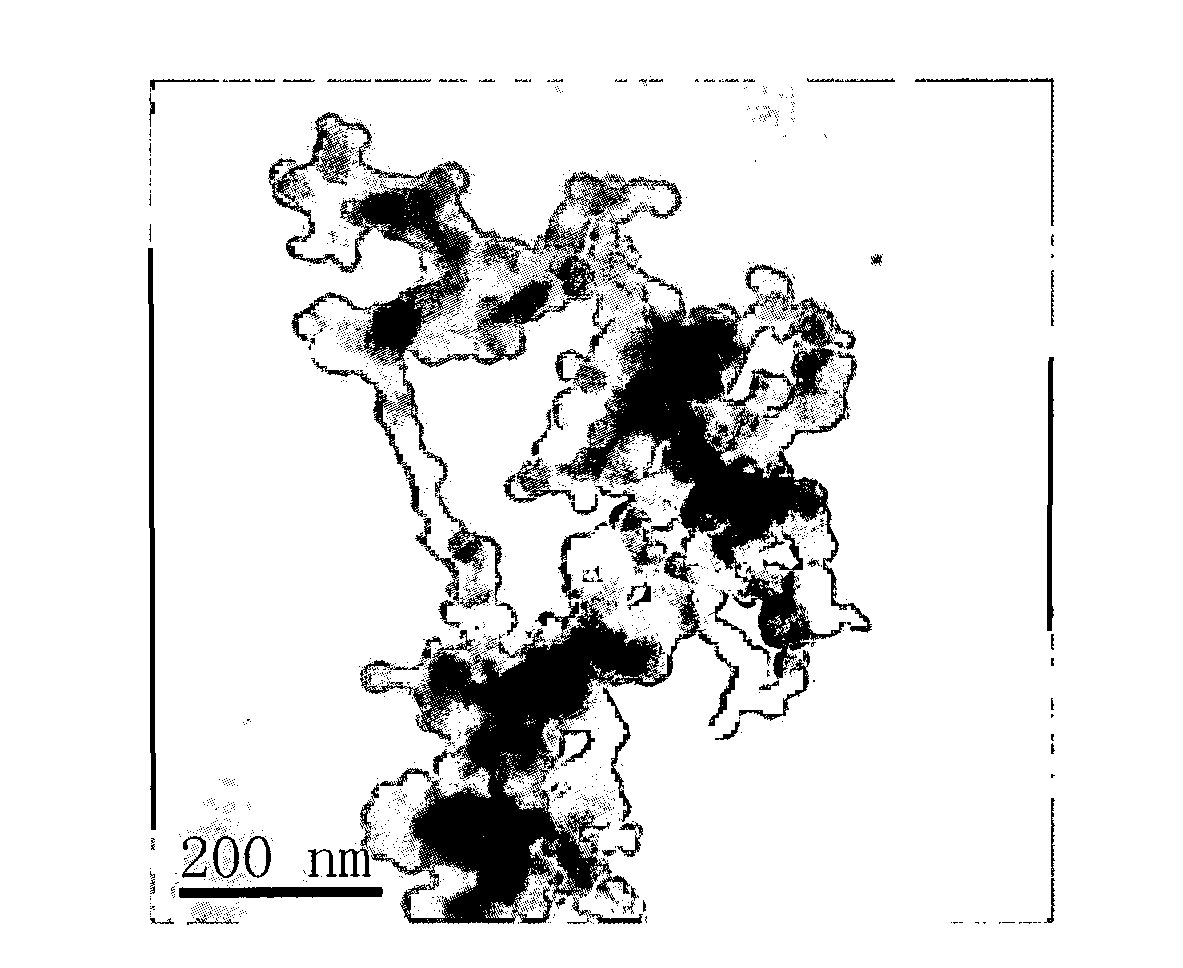

[0035] (1) Weigh 11.12g (0.04mol) FeSO respectively 4 ·7H 2 O and 21.16g (0.08mol) FeCl 3 .6H 2 O, dissolve in 250mL deionized water, add excess ammonia water to make the reaction system alkaline to pH 11, stir the reaction at 60℃, the stirring speed is 250 rpm, react for 1 hour to obtain nano ferroferric oxide particles , Washed with ethanol and distilled water to pH 7, and then vacuum dried at 60°C for 12 hours.

[0036] (2) Weigh 3g of nano ferroferric oxide prepared in step (1), disperse it in 250mL of ethanol solution, stir at a constant temperature of 50°C, rotate at 500 rpm, add 20mL of oleic acid, and react for 5 hours to obtain Oleic acid modified nano-ferric oxide.

[0037] (3) Dissolve 2 g of polyvinyl alcohol in 500 mL of deionized water as a dispersant; add 1 g of the oleic acid-modified nano ferroferric oxide prepared in step (2) to the dispersant configured above, at 25°C Disperse ultrasonically for 1 minute, and dissolve polymerized monomer methyl methacrylate (4mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com