Method for preparing calcium magnesium carboxylate snow-melting agent by utilizing municipal sludge

A technology of municipal sludge and calcium carboxylate, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of no competitive advantage in product cost, limited source of wood vinegar, high market price, and achieve good industrial application prospects, Significantly economical, lower handling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

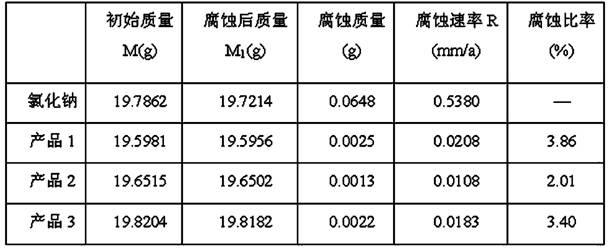

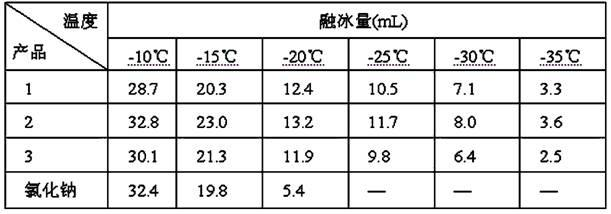

Embodiment 1

[0027] Put the sludge from the urban sewage treatment plant in the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.05-0.06g / L, and the pressure is 1.0-1.1 Under MPa, heat to 135-145°C, keep the temperature for hydrothermal reaction for 4 hours; after the reaction, let the mixture after hydrothermal oxidation reaction stand for 30 minutes, wait for solid-liquid separation, take the upper brown liquid, put it into a sealed container, and pass nitrogen 30min, add NaOH to the solution, adjust the pH value of the solution to 8-9, control the temperature at 35-38°C, and anaerobically ferment for 4 days under anaerobic conditions to obtain a brown organic acid solution after fermentation; Add tributyl phosphate organic extractant, the consumption of tributyl phosphate is 3%~4% (volume percentage) of the total amount of fermented liquid, stir evenly, leave standstill 40min, filter, obtain the light gr...

Embodiment 2

[0029] Put the sludge from the urban sewage treatment plant in the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.06-0.07g / L, and the pressure is 0.9-1.0 Under MPa, heat to 145-150°C, keep the temperature for hydrothermal reaction for 3.5h; Nitrogen for 30min, add Ca(OH) to the solution 2, adjust the pH value of the solution to 9-10, control the temperature at 30-35°C, and perform anaerobic fermentation under anaerobic conditions for 4 days to obtain a brown organic acid solution after fermentation; add trioctylphosphine into the brown fermentation liquid Organic extractant, the dosage of trioctylphosphine is 4%~5% (volume percentage) of the total amount of fermentation broth, stir evenly, let stand for 40min, filter, obtain the light gray solution after extraction; Good lime milk (the molar ratio of calcium and magnesium is controlled to be 3.5:6.5, and the molar ratio of calcium and magne...

Embodiment 3

[0031] Put the sludge from the urban sewage treatment plant in the hydrothermal reactor, add hydrogen peroxide with a concentration of 30% (mass percentage), the amount of hydrogen peroxide added is 0.04-0.05g / L, and the pressure is 1.1-1.2 Under MPa, heat to 130-135°C, keep the temperature for hydrothermal reaction for 3 hours; after the reaction, let the mixture after hydrothermal oxidation reaction stand for 60 minutes, wait for solid-liquid separation, take the upper brown liquid, put it into a sealed container, and pass nitrogen 40min, add NaOH to the solution, adjust the pH value of the solution to 10-11, control the temperature at 30-35°C, and anaerobically ferment for 3 days under anaerobic conditions to obtain a brown organic acid solution after fermentation; Add tributyl phosphate organic extracting agent in, the consumption of tributyl phosphate is 3%~4% (volume percentage) of the total amount of fermented liquid, stir evenly, leave standstill 30min, filter, obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com