Method for preparing dopamine-rare earth laminated film on surface of monocrystalline wafer

A monocrystalline silicon wafer and rare earth composite technology, which is applied in the field of micro-electromechanical systems, can solve the problems of difficult recycling and disposal, extended film forming cycle, and economical decline, and achieves the effects of simple configuration, low cost, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

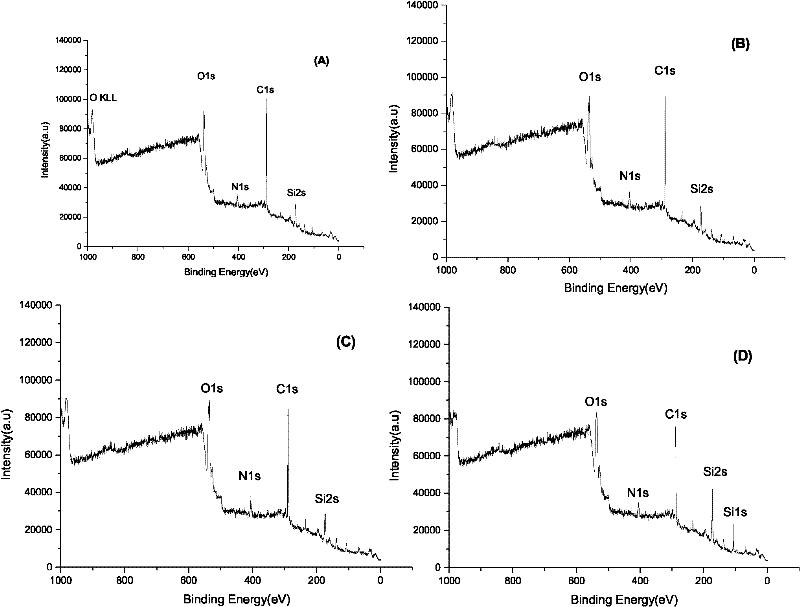

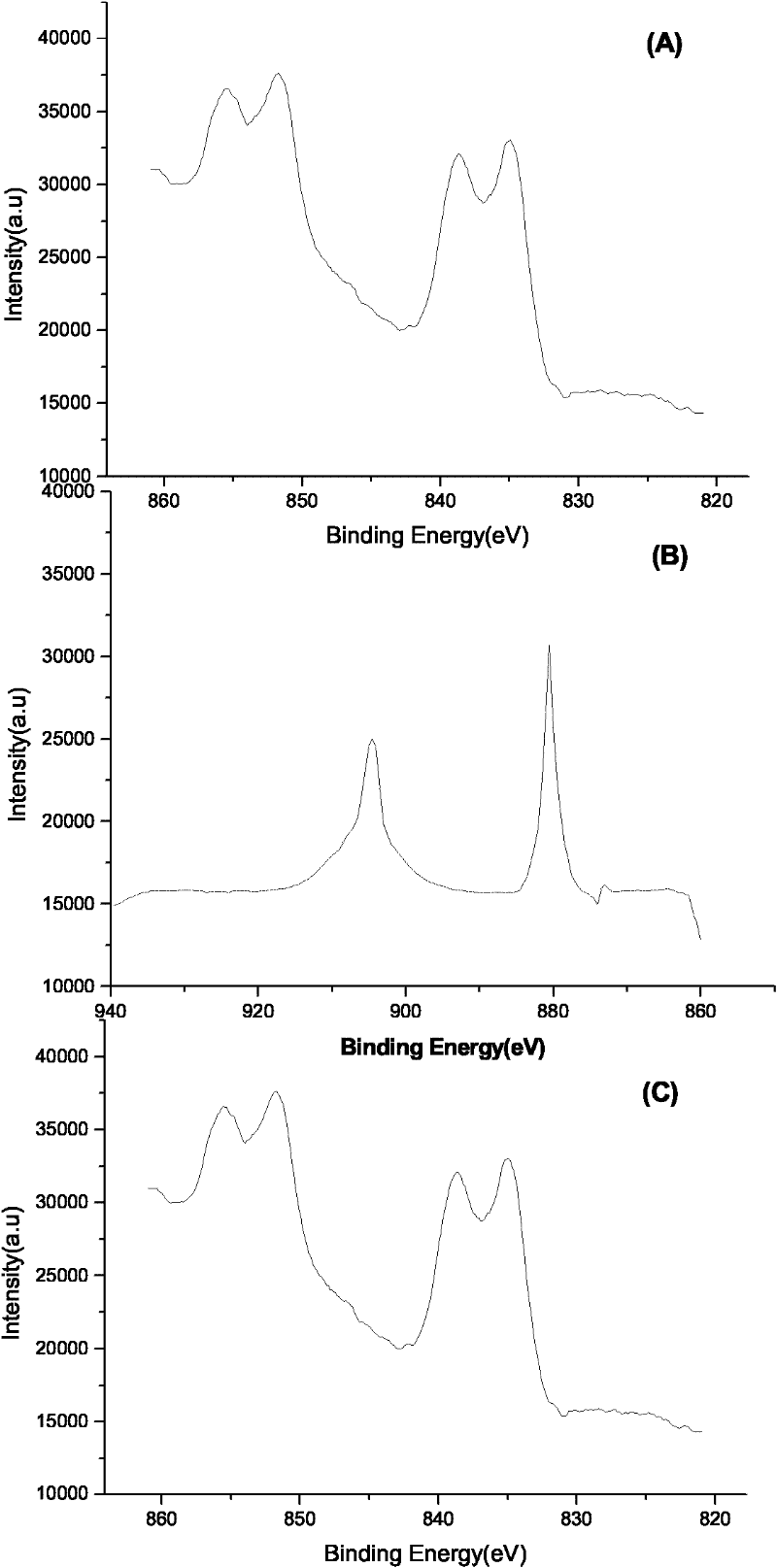

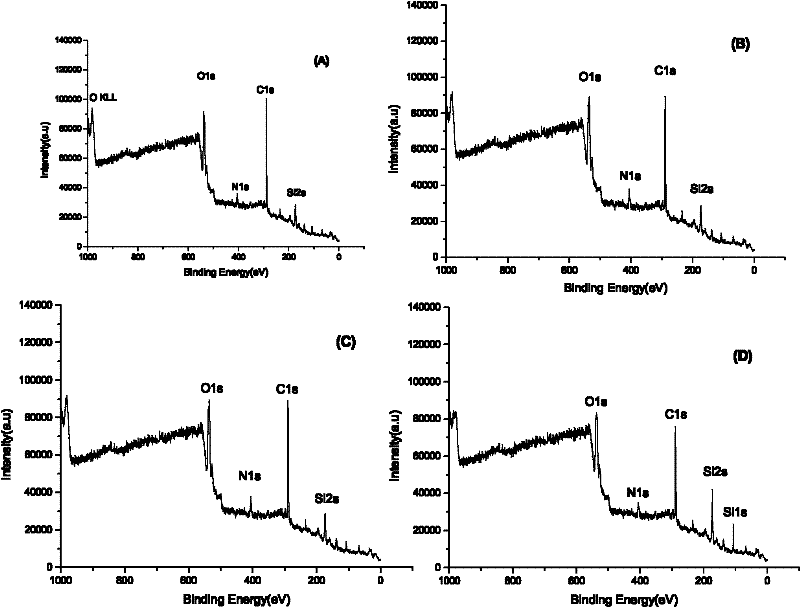

[0021] 1) Place the single crystal silicon wafer whose surface has been polished by nano-cerium oxide in ethanol, clean it with ultrasonic waves and dry it with nitrogen gas. Prepare a 0.2mM / mL dopamine aqueous solution, adjust the pH value to 8.5 with Tris acid and Hcl solution, soak a 2cm×2cm single crystal silicon in the dopamine solution, and stir magnetically at 10r / min for 2h. The monocrystalline silicon film of dopamine was taken out, washed with deionized water, and dried in vacuum;

[0022] 2) the preparation concentration is 0.3wt.% Lacl 3 solution. Lacl 3 The weight percent of solution components is: 0.3% of rare earth compound, 99.1% of ethanol, 0.5% of ammonium chloride, and 0.1% of nitric acid;

[0023] 3) Put the monocrystalline silicon polydopamine film obtained in step 1) into the rare earth solution for assembly for 20 minutes, take it out, rinse it repeatedly with deionized water, and dry it with nitrogen to obtain the dopamine rare earth composite film. ...

Embodiment 2

[0028] 1) Place the single crystal silicon wafer whose surface has been polished by nano-cerium oxide in ethanol, clean it with ultrasonic waves and dry it with nitrogen gas. Prepare a 0.4mM / mL dopamine aqueous solution, and adjust the pH value to 6 with Tris acid and Hcl solution, soak a 2cmX2cm single crystal silicon in the dopamine solution, and stir magnetically at a speed of 50r / min for 6h. After the stirring is completed, there will be deposited The monocrystalline silicon film of polydopamine was taken out, washed with deionized water, and dried in vacuum;

[0029] 2) the preparation concentration is the Secl of 0.5wt.% 3 solution. Cecl 3 The weight percent of solution components is: 0.5% of rare earth compound, 98.9% of ethanol, 0.3% of ammonium chloride, and 0.3% of nitric acid;

[0030] 3) Put the polydopamine monocrystalline silicon film obtained in step 1) into the rare earth solution for assembly for 60 minutes, take it out, rinse it repeatedly with deionized w...

Embodiment 3

[0035] 1) Place the single crystal silicon wafer whose surface has been polished by nano-cerium oxide in ethanol, clean it with ultrasonic waves and dry it with nitrogen gas. Prepare a 0.5mM / mL dopamine aqueous solution, and adjust the pH value to 8.2 with Tris acid and Hcl solution, soak a 2cmX2cm-sized monocrystalline silicon in the dopamine solution, and stir magnetically at a speed of 70r / min for 4h. After the stirring is completed, there will be deposited The monocrystalline silicon film of polydopamine was taken out, washed with deionized water, and dried in vacuum;

[0036] 2) the preparation concentration is 0.7wt.% La 2 o 3 solution. La 2 o 3The weight percent of solution components is: 0.7% of rare earth compound, 98.1% of ethanol, 0.9% of ammonium chloride, and 0.3% of nitric acid;

[0037] 3) Put the polydopamine monocrystalline silicon film obtained in step 1) into the rare earth solution for assembly for 120 minutes, take it out, rinse it repeatedly with dei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com