Method for preparing polypyrrole coated bacterial cellulose nanometer electric-conduction composite material by utilizing bacterial cellulose as template

A bacterial cellulose and nano-conductive technology, which is applied in the field of preparation of polypyrrole-coated bacterial cellulose nano-conductive composite materials, can solve the problems of low electrical conductivity, poor mechanical properties, and limited polypyrrole in composite materials, and achieve excellent mechanical properties. Performance, low cost, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

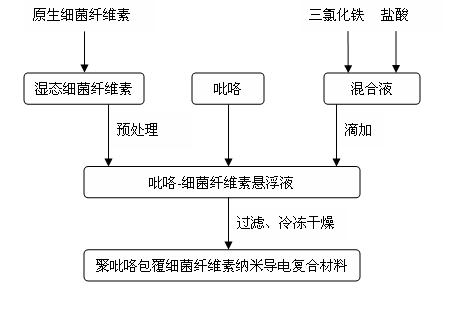

[0024] Implementation example 1: the preparation method of polypyrrole-coated bacterial cellulose nano-conductive composite material of the present invention may further comprise the steps:

[0025] In the first step, soak the native dynamically fermented bacterial cellulose nanofibers in deionized water and boil for 3 h, then add 1 mol / L NaOH solution and boil for 90 min, then wash with deionized water until neutral, centrifuge for 20 min Prepare 80% wet bacterial cellulose (stored in a refrigerator at 4°C);

[0026] In the second step, weigh 0.49 g (or 0.24 g, 2.42 g, 4.85 g) of wet bacterial cellulose, add 3 mL of deionized water, and stir to disperse the bacterial cellulose evenly;

[0027] In the third step, add pyrrole (1 mL) and DMF (1.5 mL) to the suspension in the second step in turn, and stir to make the pyrrole fully diffuse into the bacterial cellulose network;

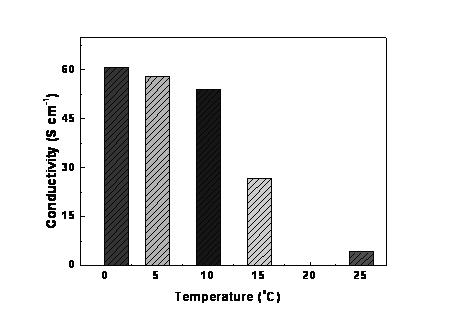

[0028] In the fourth step, the reaction system in the third step was cooled and kept at 0°C, and a mix...

Embodiment 2

[0030] Implementation example 2: the preparation method of polypyrrole-coated bacterial cellulose nano-conductive composite material of the present invention may further comprise the steps:

[0031] In the first step, soak the native dynamically fermented bacterial cellulose nanofibers in deionized water and boil for 3 h, then add 1 mol / L NaOH solution and boil for 90 min, then wash with deionized water until neutral, centrifuge for 20 min Prepare 80% wet bacterial cellulose (stored in a refrigerator at 4°C);

[0032] In the second step, weigh 0.49 g of wet bacterial cellulose, add deionized water (3 mL), and stir to disperse the bacterial cellulose evenly;

[0033] In the third step, add pyrrole (1 mL) and DMF (1.5 mL) to the suspension in the second step in turn, and stir to make the pyrrole fully diffuse into the bacterial cellulose network;

[0034]In the fourth step, the reaction system in the third step was cooled and kept at 0°C, and a mixture of FeCl3 (1.14 g or 0.57 ...

Embodiment 3

[0036] Implementation example 3: the preparation method of polypyrrole-coated bacterial cellulose nano-conductive composite material of the present invention comprises the following steps:

[0037] In the first step, soak the native dynamically fermented bacterial cellulose nanofibers in deionized water and boil for 3 h, then add 1 mol / L NaOH solution and boil for 90 min, then wash with deionized water until neutral, centrifuge for 20 min Prepare 80% wet bacterial cellulose (stored in a refrigerator at 4°C);

[0038] In the second step, weigh 0.49 g of wet bacterial cellulose, add deionized water (3 mL), and stir to disperse the bacterial cellulose evenly;

[0039] In the third step, add pyrrole (1 mL) and DMF (1.5 mL, or 0 mL, 3 mL, 4.5 mL, 6 mL) to the suspension in the second step, and stir to make the pyrrole fully diffuse into the bacterial cellulose network;

[0040] In the fourth step, the reaction system in the third step was cooled and kept at 0°C, and a mixture of F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com