Preparation method of printable black polyimide film

A technology of polyimide and polyamic acid is applied in the field of preparation of printable polyimide black film, which can solve the problems of difficult adhesion and printing, and achieve easy printing, increase surface tension and good surface adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

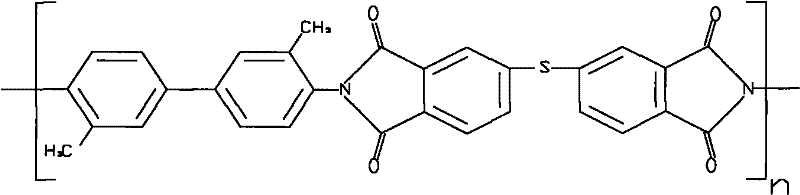

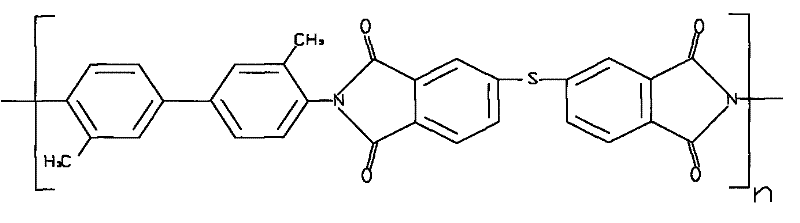

[0013] Specific implementation mode one: as attached figure 1 The preparation method of the printable polyimide black film of shown molecular formula comprises the following steps:

[0014] 1. Use aromatic diamine and aromatic dianhydride to react with DMF in a polar solvent. The solid content in the solvent is 5%-40%. Under the protection of nitrogen, the reaction temperature is 20-100°C, and the reaction time is 2-2. After 10 hours, the molar ratio of the reaction substances is n+2:n, wherein n is an integer of 1-100, and the reaction is continued for 1-5 hours to obtain a polyamic acid solution with a concentration of 5%-50%. 2. Preparation of black polyimide solution: In polyamic acid solution with a concentration of 5% to 50% (5% to 30% by weight), add titanate coupling agent modified carbon black with particle size ≤ 100nm (0.5%~10% by weight) and particle size≤60nm titanate coupling agent modified nano-calcium carbonate particles (0.5%~5% by weight), adjust the weight ...

specific Embodiment approach 2

[0015] Specific implementation mode two: as attached figure 1 The preparation method of the printable polyimide black film of shown molecular formula comprises the following steps:

[0016] The difference between this embodiment and embodiment one is that the reaction temperature in step one is 30-80°C

[0017] Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: as attached figure 1 The preparation method of the printable polyimide black film of shown molecular formula comprises the following steps:

[0019] The difference between this embodiment and embodiment one is that the reaction time in step one is 4 hours

[0020] Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com