Preparation method of urethane modified tung oil vinylite

A technology of vinyl resin and tung oil, which is used in inks, non-polymer organic compound adhesives, household appliances, etc., can solve the problems of reducing VOC in formulations, solvent hazards, and banning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~24

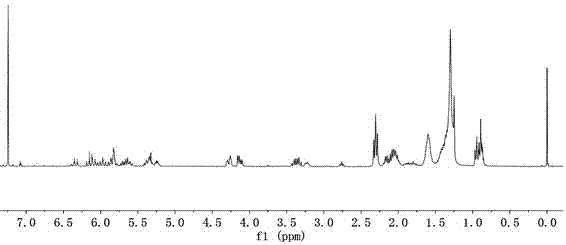

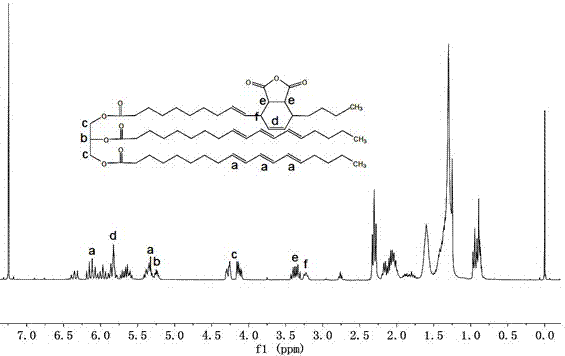

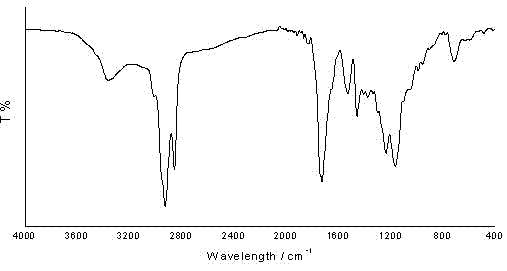

[0077] Add 100 g tung oil and the calculated amount of maleic anhydride (MAn) into a dry round bottom flask, add 0.1% p-methoxyphenol (percentage relative to the total weight of the material) under mechanical stirring, and use oil bath heating to control the temperature at 60~65°C, after the maleic anhydride in the system is completely dissolved, add a certain proportion of catalyst, and put the reaction bottle into a microwave synthesizer (WBFY201 microwave synthesizer manufactured by Gongyi Yuhua Instrument Co., Ltd., rated output power 750 W), connected to the reflux condenser, inner coil cooling water device and mechanical stirrer, set the microwave output power through the microwave instrument output power adjustment on-off switch, temporarily set the reaction time to 60 min, and the temperature is controlled at 60~140°C Selected and controlled, 5 minutes after the start of the reaction, samples were taken every 3 minutes, and reserved for NMR determination to monitor the ...

Embodiment 25

[0084] Synthesis of Isophorone Diamine-N,N'-bis(hydroxyethyl formate)

[0085] Add the measured isophorone diamine (0.1mol) and ethylene carbonate (0.2mol) into a 100mL three-necked flask equipped with a mechanical stirrer, thermometer and nitrogen protection device, stir mechanically, and control the temperature at 60°C. After the solids in the system were completely melted, 0.5% of the total mass of the system was added as yttrium acetate as a catalyst, the temperature of the system was raised to 100°C, and the reaction was carried out at a constant temperature for 4 hrs. The conversion of ethylene carbonate was completely detected by infrared spectroscopy without post-treatment, and isoflurane was obtained. Keltone-N,N'-bis(hydroxyethyl formate), the H NMR spectrum detection is consistent with the target structure. The chemical structure is shown in formula [5].

[0086]

[0087] Formula [5].

Embodiment 26

[0089] Synthesis of 1,6-hexanediamine-N,N'-bis(hydroxyethyl formate)

[0090] Add measured 1,6-hexanediamine (0.1mol) and ethylene carbonate (0.2mol) into a 100mL three-neck flask equipped with a mechanical stirrer, thermometer and nitrogen protection device, stir mechanically, and control the temperature at 60°C. After the solids in the system were completely melted, yttrium acetylacetonate accounting for 0.5% of the total mass of the system was added as a catalyst, the temperature of the system was raised to 100°C, and the reaction was carried out at a constant temperature for 3 hrs. The complete conversion of ethylene carbonate was monitored by infrared spectroscopy without post-treatment, and the obtained 1,6-Hexamethylenediamine-N,N'-bis(hydroxyethyl formate), the H NMR spectrum detection is consistent with the target structure. The chemical structure is shown in formula [6].

[0091]

[0092] Formula [6].

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com