Device and method for drying by integrating vacuum, microwave and ice temperature technologies

A vacuum drying and drying technology, which is applied in the direction of drying solid materials, partial agitation dryers, and static material dryers, etc., can solve the problems of insufficient heat sensitivity and retention of biologically active substances, low quality of dried materials, and long drying time. To achieve the effect of shortening drying time, high drying efficiency and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

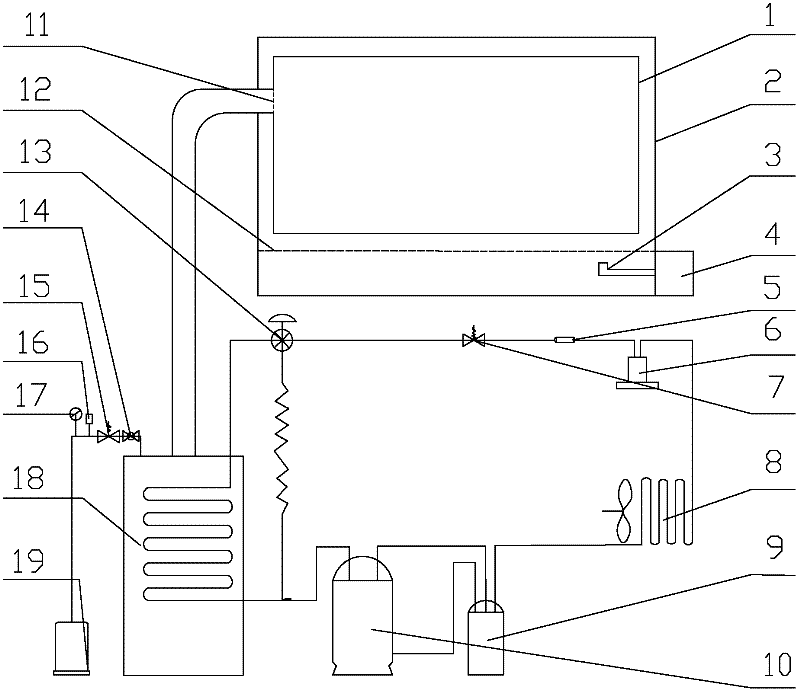

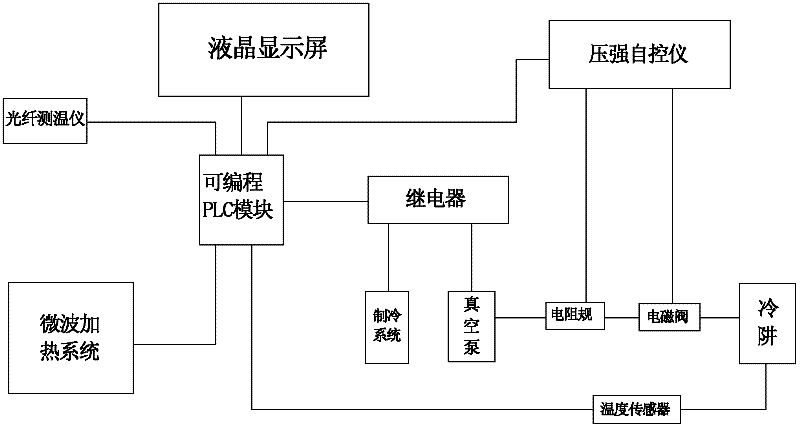

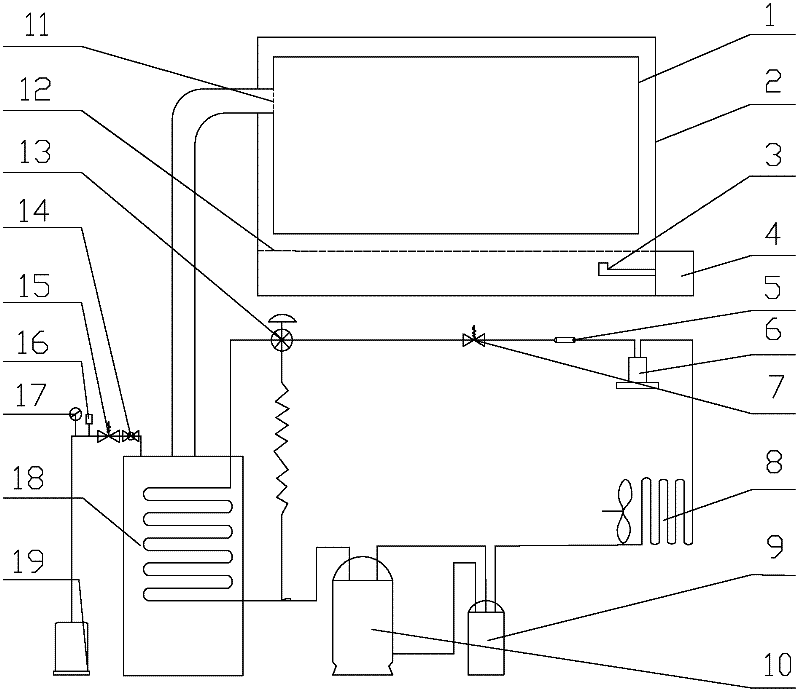

[0043] Slice food materials such as carrots and apples into the inner drying chamber, then close the vacuum drying chamber 1, start the refrigeration system to cool the cold trap 18, and start the vacuum pump 19 to evacuate the vacuum drying chamber 1 at the same time, free water on the surface of carrots and apple slices Evaporation, when the temperature is evenly lowered to the ice temperature zone (0~-5°C), maintain a certain degree of vacuum, start the microwave heating system to provide corresponding heat energy for the material to evaporate moisture, and the detection and control system detects the vacuum pressure, material temperature and microwave power in due course, and Automatically adjust the microwave power, control the microwave heating energy, and keep the material to be dried in the ice temperature zone until the end of the first sublimation drying; obtain high-quality dried carrots and apples with good color and rehydration properties.

Embodiment 2

[0045] Using the same drying process and process as in Example 1, put the bottled bioprotein medicines into the vacuum drying chamber 1, start the refrigeration system to cool down the cold trap 18, and start the vacuum pump 19 to vacuum the vacuum drying chamber 1 at the same time, pay attention to control The speed of vacuuming prevents splashing of liquid biological protein medicines. During the vacuuming process, part of the water evaporates, and the temperature of the biological medicine itself cools down. Sublimation of partially frozen water provides corresponding heat energy. The detection and control system timely detects vacuum pressure, material temperature and microwave power, and automatically adjusts microwave power, controls microwave heating energy, and keeps the material to be dried in the ice temperature zone until the end of the first sublimation drying; Higher quality biopharmaceuticals can be obtained that retain the activity of the biopharmaceuticals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com