Fermented feed

A technology for fermenting feed and raw materials, applied in animal feed, animal feed, microorganisms, etc., can solve the problems of lack of cellulase, incomplete enzyme system, insufficient enzyme amount, etc., to inhibit reproduction, improve digestion and absorption rate, and improve digestion capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

[0018] 1. Materials

[0019] 1.1 Strains

[0020] Lactobacillus acidophilus ACCC10637, Candida utilis ACCC20060, and Bacillus subtilis ACCC10619 were purchased from China Agricultural Microorganism Culture Collection Center.

[0021] 1.2 Strain Activation and Shake Flask Medium

[0022] Lactobacillus acidophilus ACCC10637: Activated with MRS agar medium and rejuvenated, made shake flask seeds with MRS liquid medium.

[0023] Candida utilis ACCC20060: Activated with YPD agar medium and rejuvenated, made shake flask seeds with wort medium.

[0024] Bacillus subtilis ACCC10619: Activated with LB agar medium and rejuvenated, made shake flask seeds with LB liquid medium.

[0025] 1.3 Strain production medium:

[0026] Soybean whey was used as the raw material of the liquid medium to expand the culture of Lactobacillus acidophilus ACCC10637 and Bacillus subtilis ACCC10619 respectively, and the inoculum size was 10%. The culture conditions were: temperature 37°C, mixer speed 100r...

Embodiment ( 2

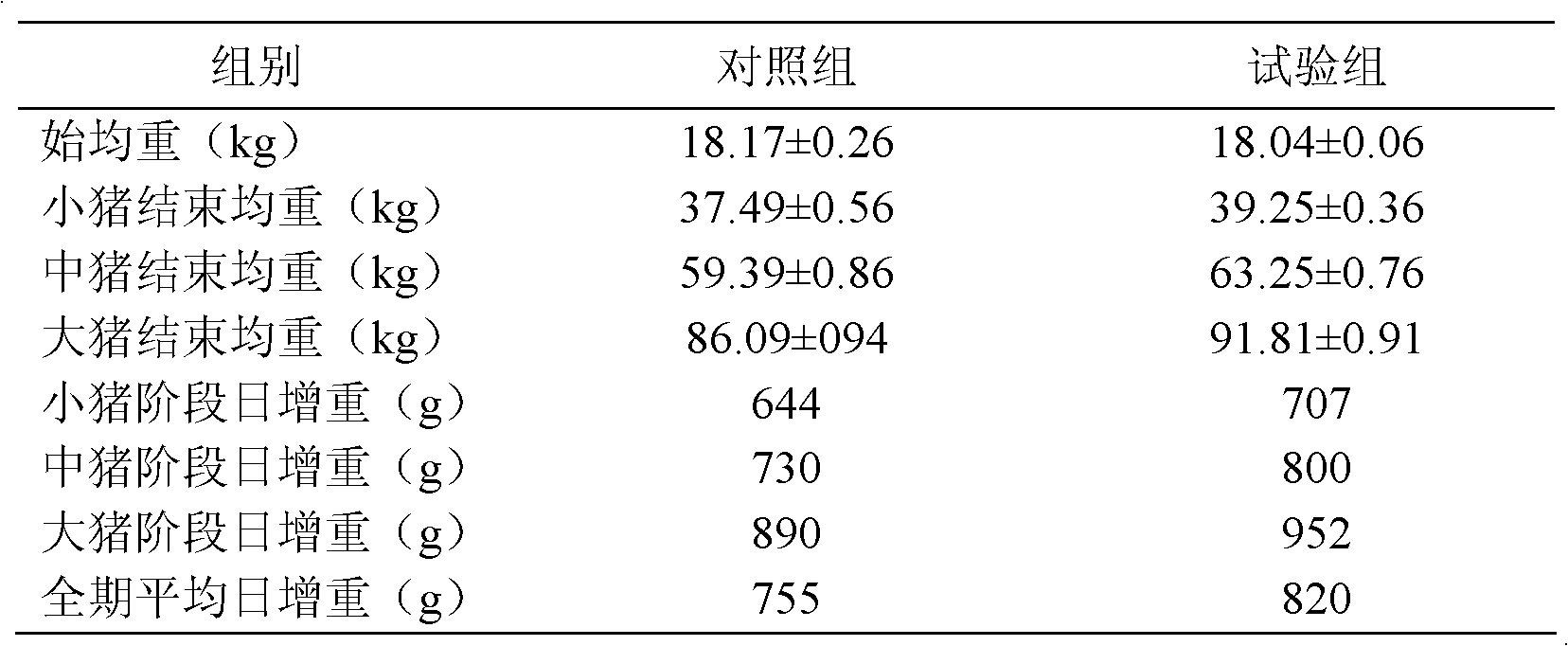

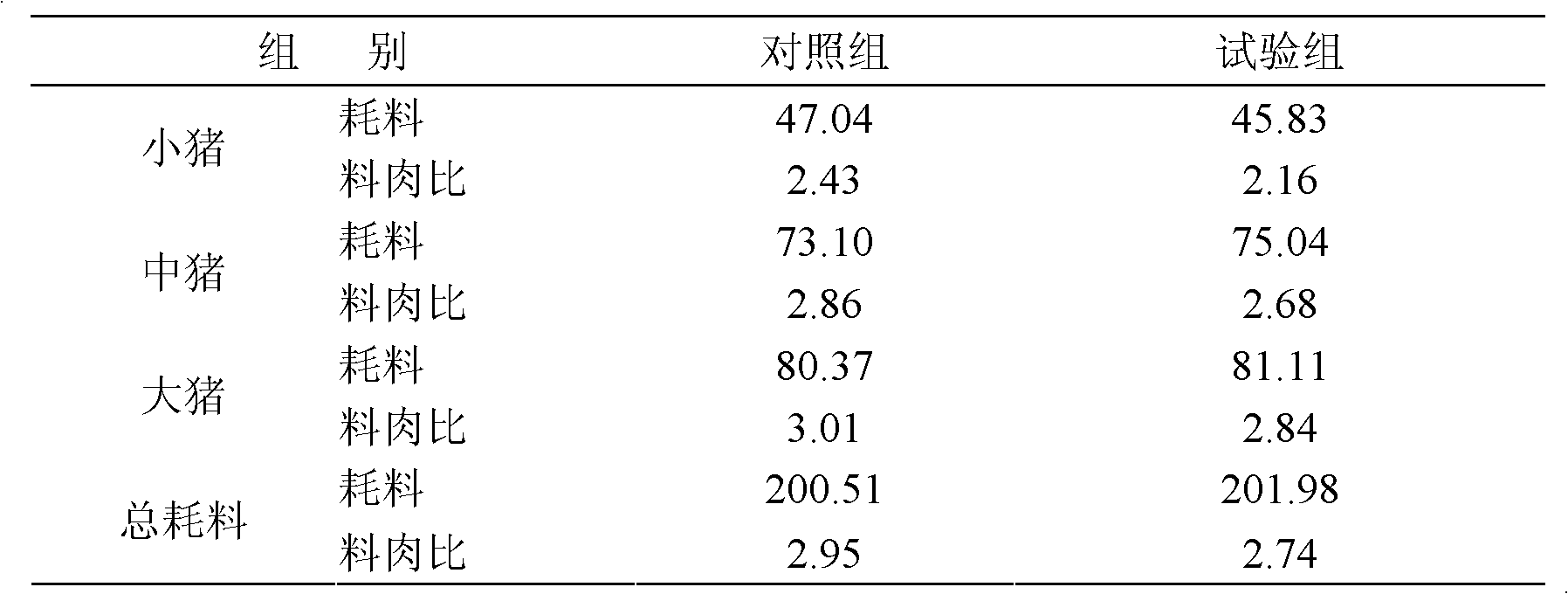

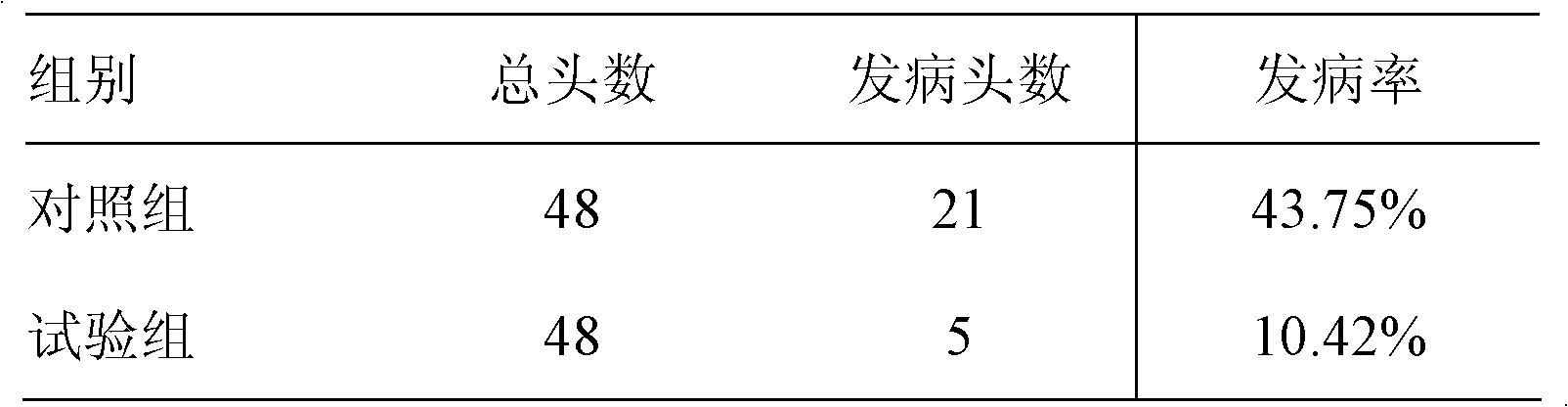

[0035] Select 96 healthy piglets with similar age and body weight (18 ± 1) kg, and randomly divide them into two groups, namely, the experimental group and the control group, with 48 piglets in each group, 4 replicates in each group, and 4 replicates in each replicate. 12 heads, half male and half female in each group. The test group was fed with ordinary full-price feed, and the test group added fermented feed to the ordinary full-price feed at a rate of 10% (that is, 1 kg of fermented feed was added to every 9 kg of ordinary full-price feed). The test time of each stage is 34 days for small pigs, 35 days for medium pigs and 28 days for large pigs.

[0036] During the 7 days of the pre-test period, the pigs were observed, immunized, driven out and ear-numbered, and the test materials were gradually transferred. Entering the test period, the two test groups were fed with the corresponding test rations, fed twice a day, and the pigs had free access to food and water. Clean the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com