Manufacturing process of subminiature inductor

A manufacturing process, ultra-small technology, applied in the field of manufacturing ultra-small inductors, can solve the problems that cannot completely replace the wire-wound chip inductors, poor inductance performance, large inductance thickness, etc., to facilitate the rapid production of machine automation, The effect of improving the qualified rate of products and reducing the amount of wire rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

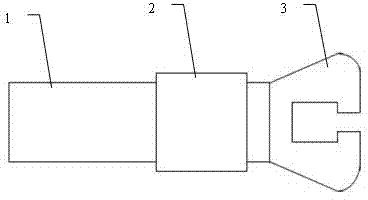

[0017] as attached figure 1 , attached figure 2 As shown, a manufacturing process of ultra-small inductors includes the I-shaped magnetic core electroplating process, winding process, DC welding process, and magnetic glue coating process. First, a metal layer is electroplated on the two bottom surfaces of the I-shaped magnetic core as Electrodes, and then put the I-shaped magnetic core on the fixture of the spot welding machine for winding, and then use the spot welding machine DC welding process that is convenient for automatic operation to carry out spot welding connection, and finally cover the inductance coil with magnetic epoxy resin glue surface layer.

[0018] The electroplating process of the I-shaped magnetic core is to electroplate a metal layer on the two bottom surfaces of the I-shaped magnetic core (4) as electrodes, so as to compress the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com