Preparation method of 4-vinylphenol

A technology of vinyl phenol and biomass materials, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., to achieve the effects of short reaction cycle, low price and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of 4-vinylphenol, comprises the following steps:

[0023] Under anaerobic or hypoxic conditions, the biomass material is subjected to a pyrolysis reaction at 200°C to 500°C, and the pyrolysis gas is collected, and the biomass material is a biomass material containing lignin and cellulose;

[0024] After the pyrolysis gas is condensed, 4-vinylphenol is obtained.

[0025] The invention prepares 4-vinylphenol by using low-cost, wide-sourced and renewable biomass materials as raw materials, has simple process, short reaction cycle, and low requirements on reaction equipment and reaction conditions.

[0026] In the present invention, the biomass material is a biomass material containing lignin and cellulose, including various agricultural and forestry residues, such as crop straws, wood waste, etc., preferably gramineous biomass materials, more preferably sugar Bamboo, corncobs, sorghum stalks, bagasse, rice straw, wheat s...

Embodiment 1

[0040] Using bagasse as raw material, crush 1 kg of bagasse to a particle size of less than 1 mm, and then pyrolyze the crushed bagasse at 300°C for 15 minutes under the condition of nitrogen gas, collect the pyrolyzed gas, and condense it with liquid nitrogen Finally, a liquid containing 4-vinylphenol is obtained;

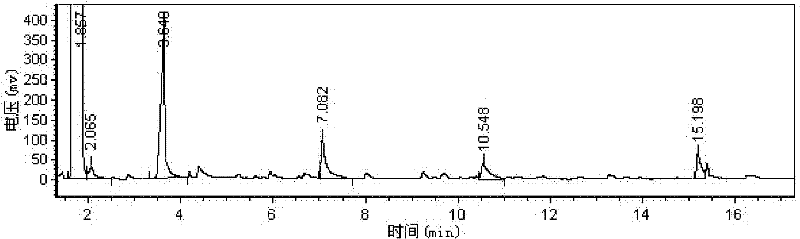

[0041] Described liquid is carried out gas chromatographic analysis, the result sees figure 1 , figure 1 The gas chromatogram of the liquid that is the embodiment of the present invention 1 obtains, figure 1 Among them, the peak that appears between 15min~16min is the characteristic peak of 4-vinylphenol, shows that described liquid contains 4-vinylphenol, and its weight content is 5.2%.

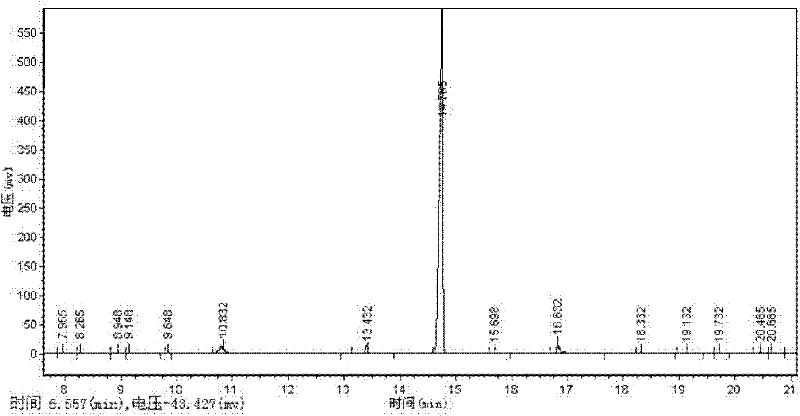

[0042] The liquid was washed 5 times with distilled water, and the organic phase was collected; the organic phase was treated with a rotary evaporator and subjected to vacuum distillation, and fractions at 50°C to 120°C were collected; the fractions were sequentially separated...

Embodiment 2

[0044] Using bagasse as raw material, crush 1 kg of bagasse to a particle size of less than 1 mm, and pyrolyze the crushed bagasse at 500°C for 15 minutes under the condition of nitrogen gas, collect the pyrolyzed gas, and condense it with liquid nitrogen Finally, a liquid containing 4-vinylphenol is obtained;

[0045] The liquid was analyzed by gas chromatography, and the result showed that the weight content of 4-vinylphenol was 13.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com