Method for extracting camellia oil and tea saporin from tea seeds

A technology for camellia oil and camellia seeds, which is applied in chemical instruments and methods, fat oil/fat production, sugar derivative preparation, etc., can solve the problems of increasing process complexity, environmental pollution, and many equipment, and achieves easy recovery and reuse. , The effect of reducing production cost and excellent oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Example 1 :Using the method of the present invention to extract tea seed oil and tea saponin

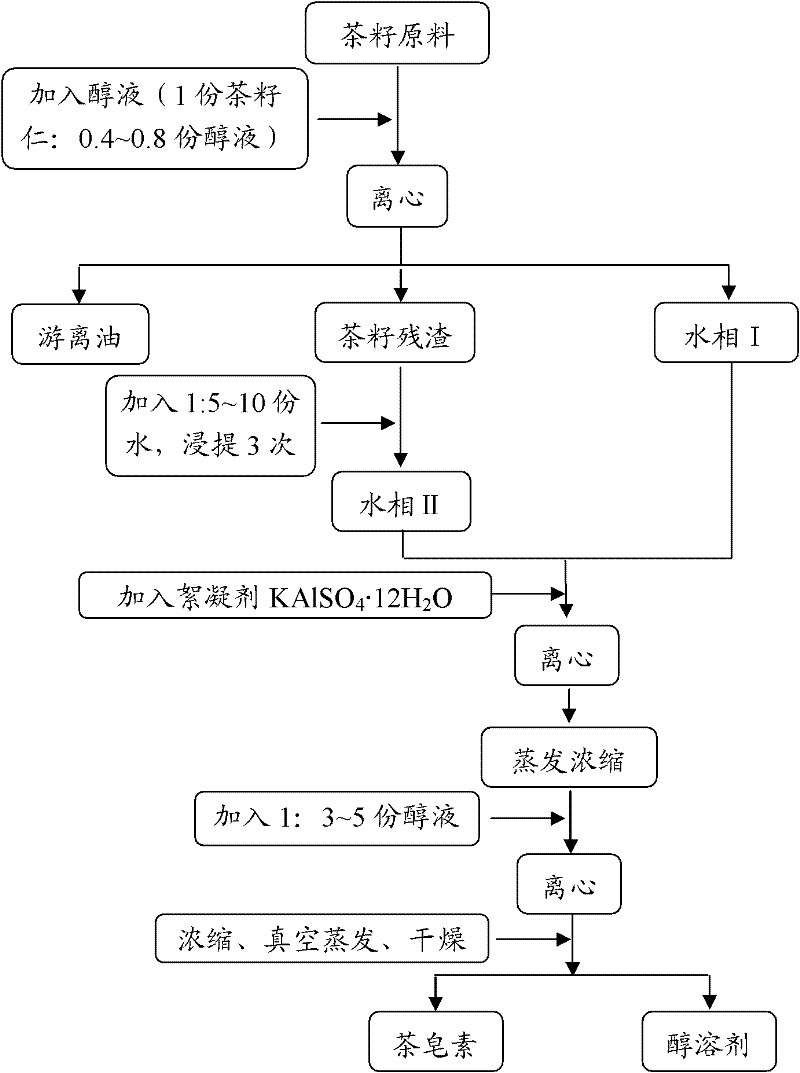

[0078] The method implementation process is as figure 1 As shown, the specific implementation steps are as follows:

[0079] Step A: After pulverizing the camellia seed kernel obtained after shelling the camellia seed from Anhui Huishan Camellia Oil Co., Ltd., a material with a particle size of 150 mesh is obtained. Mix 1 part by weight of the pulverized camellia seed kernel with 4 parts by weight of water, and then add 0.5 parts by weight of 95% alcohol solution, mixed uniformly at a temperature of 50°C and a stirring speed of 70 rpm to obtain a pretreatment mixture of camellia seed kernels;

[0080] Step B: Adjust the pH of the camellia seed kernel pretreatment mixture obtained in step A) to 8 with 1N sodium hydroxide solution, then extract with water for 1 hour at a temperature of 40°C, and then centrifuge at 2500rpm to obtain tea seeds An oil phase, an aqueous phase and a camel...

Embodiment 2

[0085] Example 2 :Using the method of the present invention to extract tea seed oil and tea saponin

[0086] The method implementation steps are as follows:

[0087] Step A: Camellia seed kernels obtained after dehulling the camellia seed oil purchased from Anhui Huishan Camellia Oil Co., Ltd. are crushed to obtain a material with a particle size of 200 meshes. Mix 1 part by weight of crushed camellia seed kernels with 4 parts by weight of water, and then add 0.8 parts by weight of a 95% alcohol solution, mixed uniformly under the conditions of a temperature of 60°C and a stirring speed of 80 rpm, to obtain a camellia seed kernel pretreatment mixture;

[0088] Step B: Adjust the pH of the camellia seed kernel pretreatment mixture obtained in step A) to 9 with 1N sodium carbonate aqueous solution, then extract with water for 2 hours at a temperature of 50°C, and then centrifuge at 4000 rpm to obtain tea seed oil Phase, water phase and camellia seed residue phase; said tea seed oil p...

Embodiment 3

[0093] Example 3 :Using the method of the present invention to extract tea seed oil and tea saponin

[0094] The method implementation steps are as follows:

[0095] Step A: After pulverizing the camellia seed kernels obtained after shelling of the camellia seed oil purchased from Anhui Huishan Camellia Oil Co., Ltd., a material with a particle size of 100 mesh is obtained, and 1 part by weight of the pulverized camellia seed kernel and 3 parts by weight of water are mixed uniformly, and then added 0.4 parts by weight of a 95% alcohol solution, mixed uniformly under the conditions of a temperature of 50°C and a stirring speed of 70 rpm to obtain a camellia seed kernel pretreatment mixture;

[0096] Step B: The pretreatment mixture of camellia seed kernels obtained in step A) was adjusted to pH 7 with 1N sodium hydroxide aqueous solution, and then extracted with water for 0.5h at a temperature of 60°C, and then centrifuged at 1500rpm to obtain tea Seed oil phase, water phase and cam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com