Method for preparing lead carbonate combustion catalyst used for solid propellant

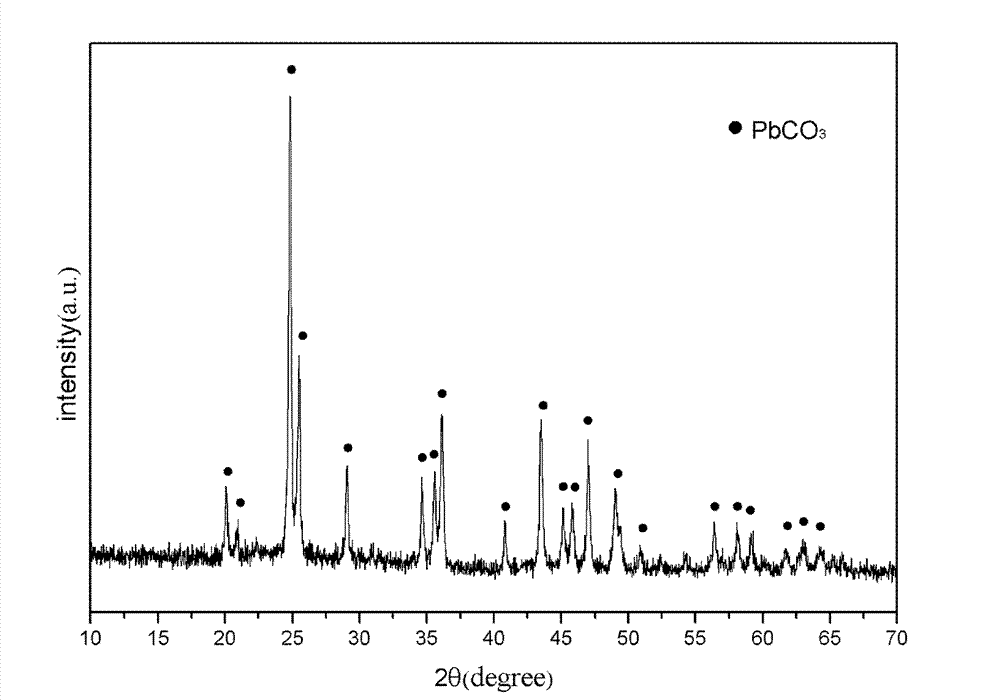

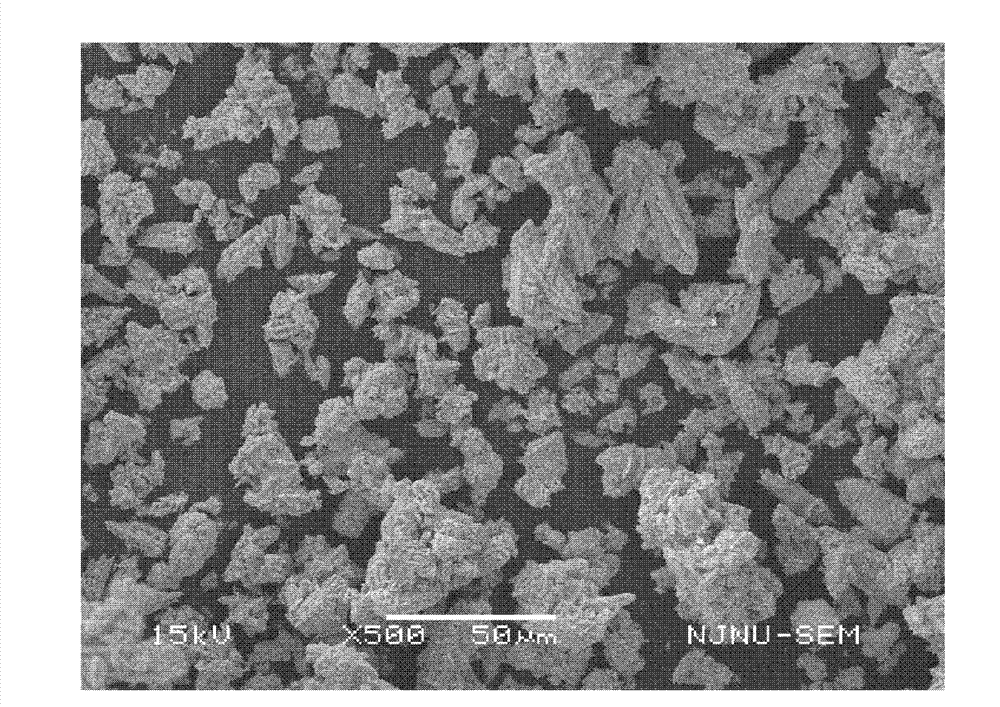

A technology of burning catalysts and solid propellants, which can be used in the production of lead carbonate, compressed gas, and offensive equipment. It can solve the problems of wide particle size distribution of finished powder, troubles in industrialization, and high supersaturation, and achieve narrow particle size distribution. , easy large-scale production, high sintering activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This embodiment includes the following steps:

[0021] Step 1: Take a certain amount of Pb(NO 3 ) 2 The powder is added to the ethylene glycol solution to obtain a solution;

[0022] Step 2: adjusting the concentration of lead ions in the solution obtained in Step 1 to 0.1mol / L, and then stirring the solution for 1 hour;

[0023] Step 3: adding a certain volume of the solution in step 2 to the inner lining of the autoclave, and the volume of the solution reaches 70% of the volume of the inner lining of the autoclave;

[0024] Step 4: Place the lining of the reaction kettle equipped with the reaction materials in step 3 in a high-pressure reaction kettle, seal the reaction kettle, heat it at 200°C for 8 hours for solvent heat treatment, and then lower it to room temperature;

[0025] Step 5: taking out the reactant from the autoclave, filtering and washing with deionized water and absolute ethanol in sequence, and drying at 80°C for 12 hours to obtain lead carbonate ...

Embodiment 2

[0027] This embodiment includes the following steps:

[0028] Step 1: Take a certain amount of Pb(NO 3 ) 2 Powder, added to ethylene glycol methyl ether solution to obtain Pb(NO 3 ) 2 organic solution;

[0029] Step 2: adjusting the concentration of lead ions in the solution obtained in Step 1 to 0.3mol / L, and then stirring the solution for 3 hours;

[0030] Step 3: adding a certain volume of the solution in step 2 into the inner lining of the autoclave, and the volume of the solution reaches 60% of the volume of the inner lining of the autoclave;

[0031] Step 4: Place the lining of the reactor with the reaction materials in Step 3 in a high-pressure reactor, seal the reactor, heat it at 150°C for 10 hours for solvent heat treatment, and then lower it to room temperature;

[0032] Step 5: taking out the reactants from the autoclave, filtering and washing with deionized water and absolute ethanol in sequence, and drying at 600°C for 10 hours to obtain lead carbonate powd...

example 3

[0034] This embodiment includes the following steps:

[0035] Step 1: Weigh a certain amount of PbO powder and add it to the ethylene glycol methyl ether solution to obtain an organic solution of PbO;

[0036] Step 2: Adjust the concentration of lead ions in the solution obtained in Step 1 to 1 mol / L, and stir the solution for 2 hours.

[0037] Step 3: adding a certain volume of the solution in step 2 into the inner lining of the autoclave, and the volume of the solution reaches 80% of the volume of the inner lining of the autoclave;

[0038] Step 4: Place the lining of the reaction kettle equipped with the reaction materials in step 3 in a high-pressure reaction kettle, seal the reaction kettle, heat it at 180oC for 16 hours for solvent heat treatment, and then lower it to room temperature;

[0039] Step 5: Take out the reactants from the autoclave, filter and wash with deionized water and absolute ethanol in sequence, and dry at 180°C for 16 hours to obtain lead carbonate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com