Water-soluble polyurethane and preparation method thereof, and water-soluble ink composition containing water-soluble polyurethane and preparation method thereof

A technology of water-based polyurethane and water-based ink, which can be used in inks, household utensils, applications, etc., and can solve the problems of easy cracking of water-based ink layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

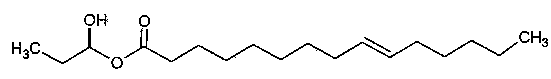

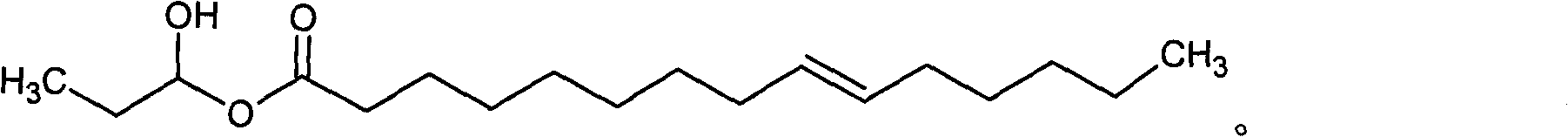

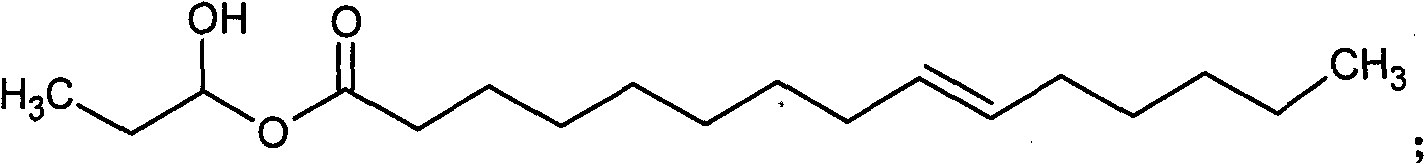

Image

Examples

preparation example Construction

[0018] The present invention also provides a kind of preparation method of above-mentioned waterborne polyurethane, described preparation method is the method for the common synthetic polyurethane of those skilled in the art, comprises the following steps:

[0019] 1) vacuum dehydration of polycarbonate diol and catalyst, adding diisocyanate to react, adding solvent to dilute the reaction system viscosity;

[0020] 2) Adding a hydrophilic chain extender and lignin to the reaction system for chain extension reaction;

[0021] 3) adding a neutralizing agent to the system after the chain extension reaction to carry out the neutralization reaction;

[0022] 4) The solvent is distilled off under reduced pressure to obtain lignin-modified polycarbonate polyurethane.

[0023] The above synthesis method is the acetone method commonly used by those skilled in the art: prepolymer synthesis - viscosity reduction with acetone - chain extension - quaternization - lignin modification - rem...

Embodiment 1

[0059] The present invention provides a synthesis of lignin-modified water-based polyurethane below.

[0060] Add 5500g relative molecular mass in the dry reactor that reflux condenser, stirred tank are housed and be the polycarbonate dibasic alcohol of 2000 and the catalyst (10% solution of dibutyltin dilaurate) of 20g, add 2500g isophorone again Diisocyanate, reacted at 60°C for 2 hours, then added 500g of acetone to reduce viscosity, then added 900g of hydrophilic chain extender dimethylolpropionic acid (DMPA) and 600g of sodium lignosulfonate and stirred, reacted for another 4 hours, and cooled to 40°C, and under stirring, add 500g of tertiary amine neutralizing agent weighed in step 1 to neutralize, and the neutralized material is divided into two parts.

[0061] Part of the acetone was distilled off under reduced pressure to obtain lignin-modified water-based polyurethane powder A11.

[0062] One part was added with 5000 g of distilled water for emulsification and stirr...

Embodiment 2

[0068] The difference from Example 1 is that the water-based ink of the present embodiment does not contain pigment, and the content of sodium lignosulfonate is 1000g to obtain water-based ink A23.

[0069] Adopting a PET sheet with a thickness of 0.125mm, adopting the water-based ink A23 of the present invention to print patterns to form a patterned PET sheet, drying to obtain a PET sheet A24 with a water-based ink pattern layer.

[0070] The in-mold injection molding was carried out according to the conditions of Example 1 to obtain the in-mold decoration A25.

[0071] Prepare 100 pieces of A25 as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com