Solar collector core with silicon nitride medium selective absorption coating and preparation method

A solar collector and selective absorption technology, applied in the field of solar thermal utilization, can solve the problems of poor weather resistance, unsuitable high-efficiency roll-to-roll or sheet-type step-by-step continuous production, etc., and achieve excellent weather resistance and excellent selective absorption characteristics. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

[0026] The invention provides a core film of a flat solar heat collector with a silicon nitride dielectric selective absorption coating. The silicon nitride or silicon oxynitride dielectric film of the present invention is produced by magnetron reactive sputtering with MF intermediate frequency power supply and paired double cathode (plane or rotating target), and the silicon nitride or silicon oxynitride dielectric film has good thermal stability and weather resistance Excellent performance and high production efficiency.

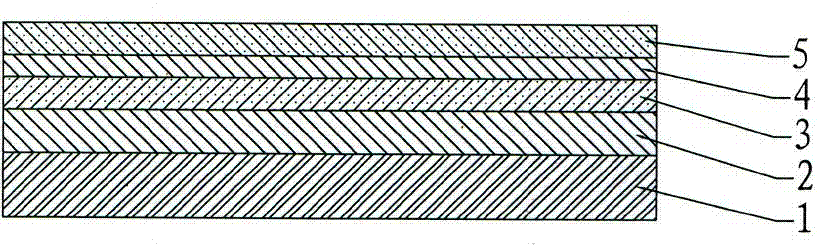

[0027] Such as figure 1 As shown, the film system of the present invention includes a substrate 1, on which a highly infrared reflective conductive film 2 is disposed, and on the highly infrared reflective conductive film 2, a silicon nitride or silicon oxynitride dielectric film 3 is disposed. Among them, the substrate 1 is m...

Embodiment 1

[0034] ① Take the substrate 1, and use cathode magnetron sputtering to prepare a conductive film 2 with high infrared reflection on the substrate 1. The thickness of the conductive film 2 with high infrared reflection is 110nm, the working voltage is 450V, and the working current is 150A , the filling gas is argon or argon mixed with nitrogen, when the filling gas is argon mixed with nitrogen, the mass ratio between argon and nitrogen is 1:2, and the working pressure is 0.4Pa;

[0035]②. On the conductive film 2 with high infrared reflection, the silicon nitride dielectric film 3 is produced by two MF intermediate frequency power supplies and the paired dual-cathode magnetron reactive sputtering. The thickness of the prepared silicon nitride dielectric film 3 is 69 nm, the working voltage is 480V, the working current is 95A, the working pressure is 0.45Pa, the working gas is argon, and the reaction gas is nitrogen or nitrogen mixed with oxygen. The mass parts of the total amou...

Embodiment 2

[0042] ① Take the substrate 1, and use cathode magnetron sputtering to prepare a conductive film 2 with high infrared reflection on the substrate 1. The thickness of the conductive film 2 with high infrared reflection is 100nm, the working voltage is 440V, and the working current is 210A , the filling gas is argon or argon mixed with nitrogen, and the working pressure is 0.42Pa. When the filled gas is argon mixed with nitrogen, the ratio between argon and nitrogen is 1:1;

[0043] ②. On the conductive film 2 with high infrared reflection, a silicon nitride dielectric film 3 is produced by using 1 MF intermediate frequency power supply and paired dual-cathode magnetron reactive sputtering. The thickness of the prepared silicon nitride dielectric film 3 is 65 nm, the working voltage is 480V, the working current is 140A, the working pressure is 0.46Pa, the working gas is argon, and the reaction gas is nitrogen or nitrogen mixed with oxygen. The mass parts of the total amount are:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com