A regeneration method and device for a selective catalytic reduction denitrification catalyst

A denitrification catalyst and selective technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve the effects of improved surface conditions, simple devices and processes, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

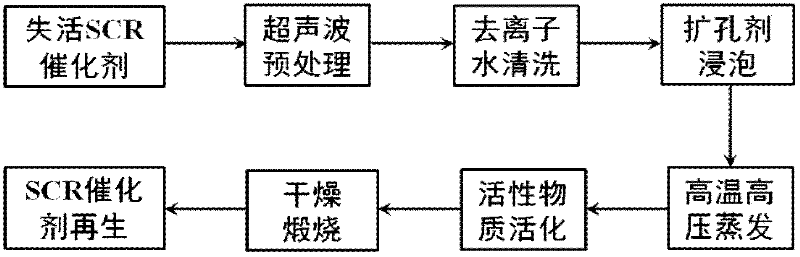

Method used

Image

Examples

Embodiment 1

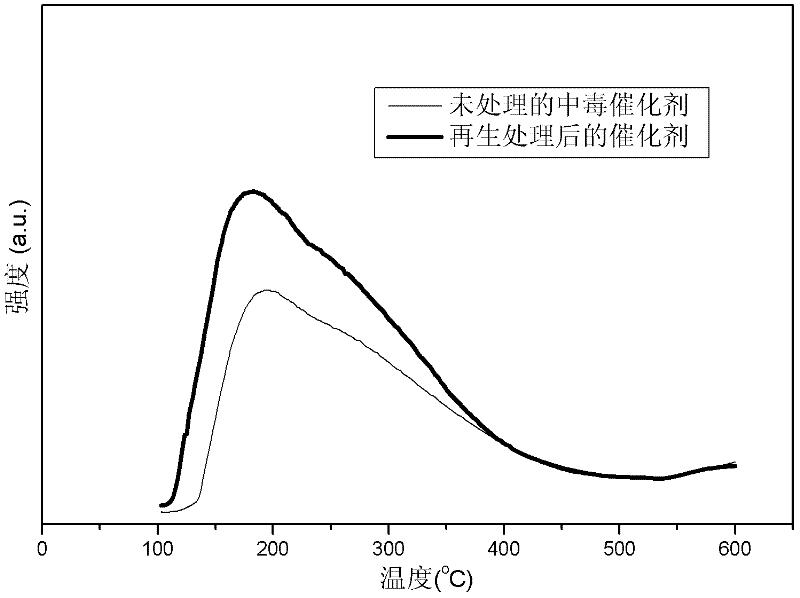

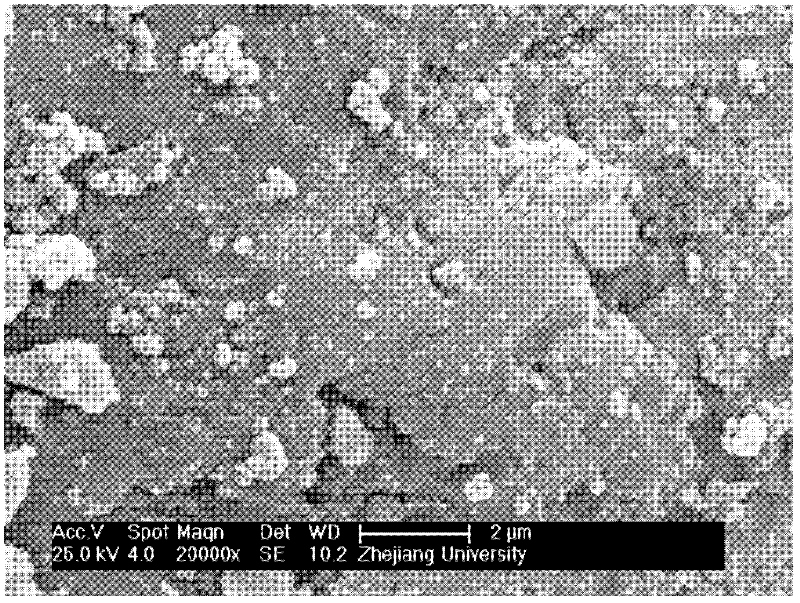

[0030] Put a 25*25*40 cellular poisoned SCR denitrification catalyst in a beaker filled with 100mL of deionized water and submerge it, put it into the purge pool for ultrasonic treatment for 10 minutes, and then place it in the immersion cleaning pool for 100mL of deionization Soak in water for 2 hours, then put it into an autoclave, pour 1L of alcohol, heat it to 275°C and keep it for 3 hours, suddenly open the vent valve to make the alcohol evaporate quickly, and finally put the catalyst in 100mL of a partial concentration of 1% by mass percentage In the mixed solution composed of ammonium vanadate solution and ammonium metatungstate solution with a concentration of 5% by mass, shake and evaporate to dryness in a water bath at 80°C, dry it in a drying oven at 110°C for 4 hours, and then put it in a muffle Calcined in a furnace at 500°C for 5 hours. The obtained samples were sieved into 40-60 mesh granules and powders for later use.

[0031] Performance Testing:

[0032] 0....

Embodiment 2

[0037] Put a 25*25*40 cellular poisoned SCR denitrification catalyst in a beaker filled with 100mL of deionized water and submerge it, put it into the purge pool for ultrasonic treatment for 10 minutes, and then place it in the immersion cleaning pool for 100mL of deionization Soak in water for 2 hours, then put it into an autoclave, pour 1L of JFC-1 solution with a mass percentage concentration of 1%, heat it to 275°C and keep it for 3 hours, suddenly open the vent valve to make the JFC-1 solution evaporate quickly, and finally put The catalyst is placed in 100mL of a mixed solution consisting of 1% ammonium metavanadate solution by mass percentage concentration and 5% ammonium metatungstate solution by mass percentage concentration, shaken and evaporated to dryness in a water bath at 80°C, and placed in a drying oven Dry at 110°C for 6 hours, and then put into a muffle furnace for 500°C for calcination for 5 hours. The obtained samples were sieved into 40-60 mesh granules an...

Embodiment 3

[0042] Put a 25*25*40 cellular poisoned SCR denitrification catalyst in a beaker filled with 100mL of deionized water and submerge it, put it into the purge pool for ultrasonic treatment for 10 minutes, and then place it in the immersion cleaning pool for 100mL of deionization Soak in water for 2 hours, then put it into an autoclave, pour 1L of methanol, heat to 275°C and keep it for 3 hours, suddenly open the vent valve to evaporate the methanol quickly, and finally put the catalyst in 100mL of a partial concentration of 1.5% by mass percentage. In the mixed solution composed of ammonium vanadate solution and ammonium metatungstate solution with a concentration of 3% by mass, shake and evaporate to dryness in a water bath at 80°C, dry it in a drying oven at 110°C for 8 hours, and then put it in a muffle furnace Calcined at 500°C for 5 hours. The obtained samples were sieved into 40-60 mesh granules and powders for later use.

[0043] Performance Testing:

[0044] 0.5 g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com