Method for preparing n-fatty acyl amino acid surfactant from oil

A technology of fatty acyl amino acid sodium and surfactant, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve problems such as complex operation process, application restrictions, environmental pollution, etc., and achieve simple synthesis route and product surface The effect of excellent activity and no pollution to the environment by the synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

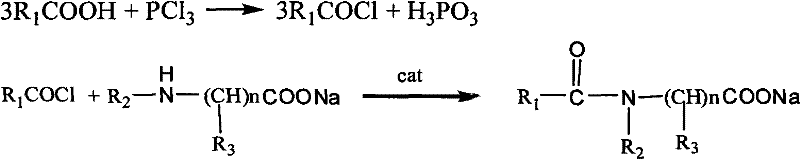

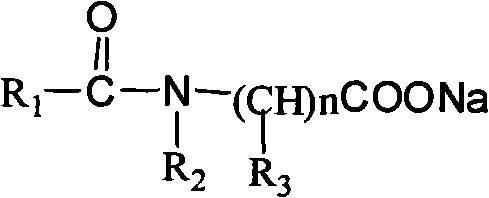

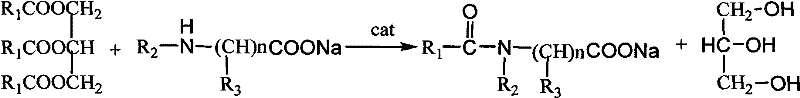

Method used

Image

Examples

Embodiment 1

[0023] Add 0.1mol coconut oil and 0.37mol sodium glycinate in a four-necked round bottom flask equipped with stirring, thermometer, water separator, and reflux condenser, add 0.4wt% potassium oxide and 4A zeolite of the reactant, after fully stirring After gradually raising the temperature to 140°C, the product was obtained after reacting for 5 hours.

Embodiment 2

[0025] Add 0.1mol peanut oil and 0.4mol sodium sarcosinate in a four-necked round bottom flask equipped with stirring, thermometer, water separator, and reflux condenser, add 0.3wt% sodium oxide and 4A zeolite of the reactant, after fully stirring After gradually raising the temperature to 155°C, the product was obtained after reacting for 5 hours. .

Embodiment 3

[0027] Add 0.1mol palm oil and 0.43mol sodium alanine in a four-neck round bottom flask equipped with stirring, thermometer, water separator, and reflux condenser, add 0.3wt% potassium oxide and 4A zeolite of the reactant, and fully stir After gradually raising the temperature to 160° C., the product was obtained after reacting for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com