Preparing method of inorganic cesium selective absorbent

A selective and adsorbent technology, which is applied in the field of separation and treatment of radioactive waste liquid, can solve the problems of fine particles that cannot be used for column operation, harsh process conditions, poor hydrolysis stability, etc., and achieve good radiation resistance and thermal stability, Good hydrolytic stability and the effect of increasing the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

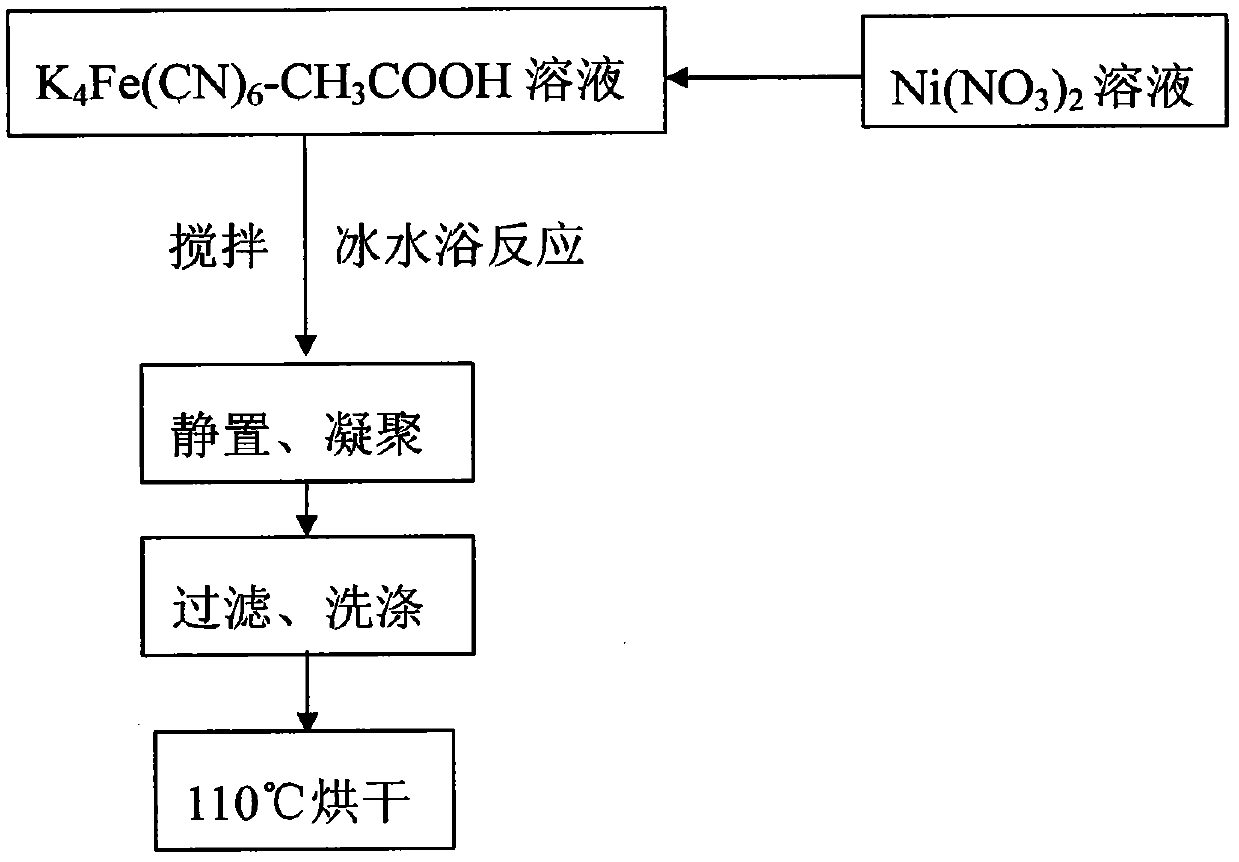

[0029] The preparation method of this inorganic cesium selective adsorbent is specifically as follows: use analytically pure K 4 Fe(CN) 6 ·6H 2 O to prepare 0.3mol / L K 4 Fe(CN) 6 -1.8×10 -3 mol / L CH 3 COOH solution. Take 100mL 0.3mol / L K 4 Fe(CN) 6 -1.8×10 -3 mol / L CH 3Put the COOH solution in a 400mL beaker, place the beaker in an ice-water bath, and add 0.5mol / L Ni(NO 3 ) 2 Solution 240mL, while adding the solution dropwise, use a stirrer to stir at 800±50rpm. After the reaction, continue to stir for 10-15min, then take out the beaker, place it at 110°C for about 2h to coagulate and settle the colloid, and pour off the supernatant . Then, transfer to a suction filter crucible for suction filtration, then wash with deionized water, then suction filter, repeat suction filtration-washing 3 to 4 times, and finally dry the precipitate at 110°C to obtain KNiFC adsorbent .

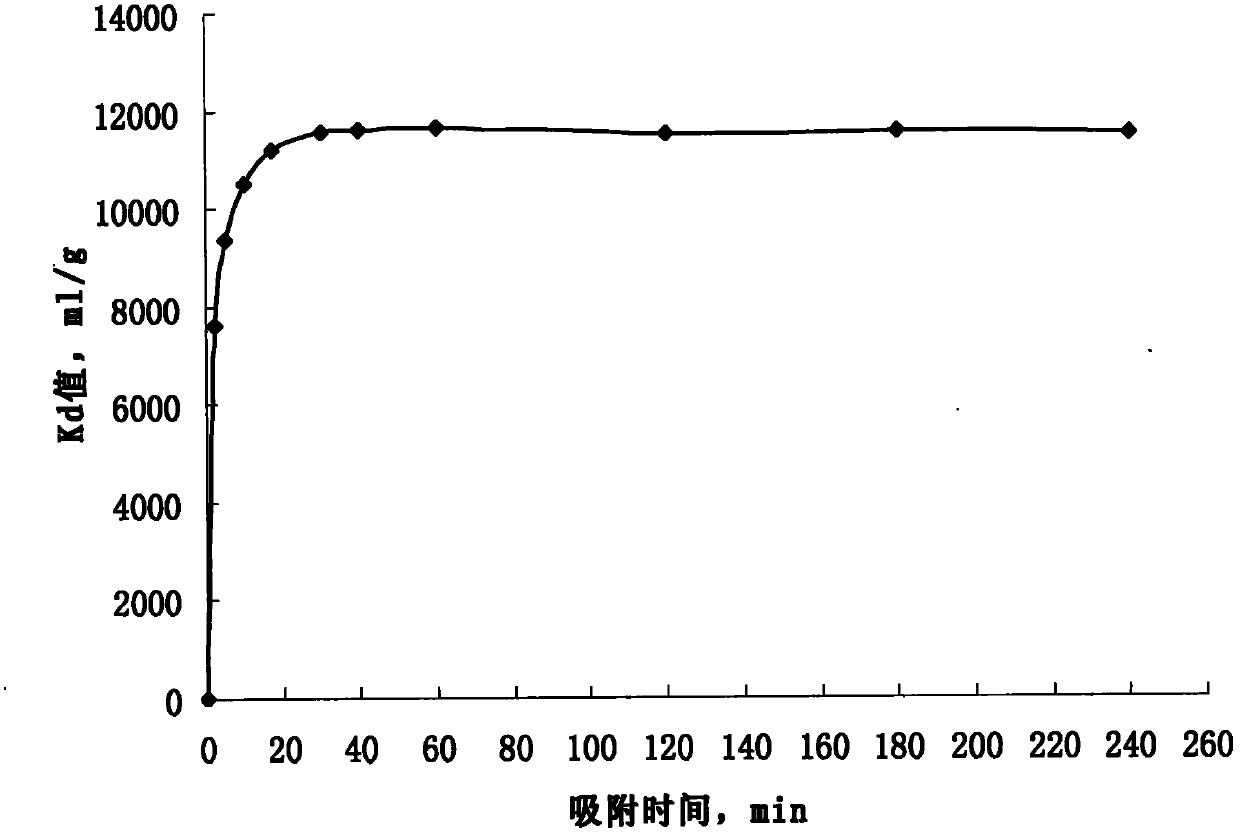

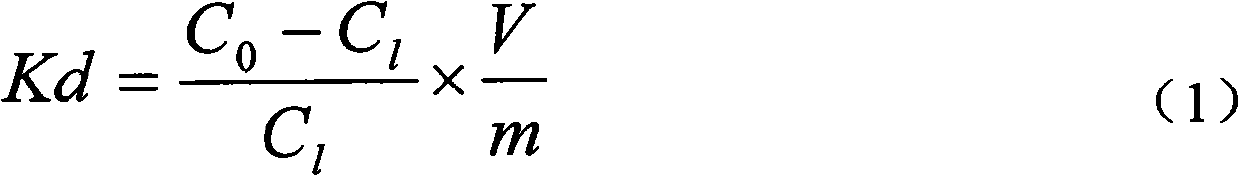

[0030] Accurately weigh 0.1081g of the above-mentioned adsorbent in a 15mL centrifuge tube, th...

Embodiment 2

[0038] Concrete operation is as embodiment 1. The specific operation is as follows: use analytically pure K 4 Fe(CN) 6 ·6H 2 O to prepare 0.1mol / L K 4 Fe(CN) 6 -1.0×10 -3 mol / L CH 3 COOH solution. Take 100mL 0.1mol / L K 4 Fe(CN) 6 -1.0×10 -3 mol / L CH 3 Put the COOH solution in a 400mL beaker, place the beaker in a water bath at 3°C, and add 0.1mol / L Ni(NO 3 ) 2 Solution 600mL, while adding the solution dropwise, use a stirrer to stir at 800±50rpm. After the reaction, continue to stir for 15-20min, then take out the beaker, place it at 120°C for about 2h to allow the colloid to coagulate and settle, and pour off the supernatant . Then, transfer to the suction filter crucible for suction filtration, then wash with deionized water, then suction filtration, repeat suction filtration-washing 3 to 4 times, and finally dry the precipitate at 120°C to obtain KNiFC adsorbent .

Embodiment 3

[0040] Concrete operation is as embodiment 1. The specific operation is as follows: use analytically pure K 4 Fe(CN) 6 ·6H 2 O to prepare 0.5mol / L K 4 Fe(CN) 6 -2.0×10 -3 mol / L CH 3 COOH solution. Take 100mL 0.5mol / L K 4 Fe(CN) 6 -2.0×10 -3 mol / L CH 3 Put the COOH solution in a 400mL beaker, place the beaker in a water bath at 5°C, and add 0.8mol / L Ni(NO 3 ) 2 Solution 187.5mL, while adding the solution dropwise, use a stirrer to stir at 800±50rpm. After the reaction, continue to stir for 15-20min, then take out the beaker, and place it at 100°C for about 2h to coagulate and settle the colloid, and pour off the supernatant liquid. Then, transfer to the suction filter crucible for suction filtration, then wash with deionized water, then suction filtration, repeat suction filtration-washing 3 to 4 times, and finally dry the precipitate at 100°C to obtain KNiFC adsorbent .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com