A kind of quaternary ammonium hexafluorophosphate ionic liquid polymer and its synthesis method

A technology of hexafluorophosphate and ionic liquid, applied in the field of new quaternary ammonium hexafluorophosphate ionic liquid polymer and its synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Synthesis of [VBTEA]Cl. Add 3.393g of p-chloromethylstyrene and 2.021g of triethylamine into a 100mL three-necked round-bottomed flask, then add 15mL of anhydrous acetonitrile, stir and react at 45°C for 12h, there will be precipitates in the solution, after the reaction , the mixture was poured into diethyl ether to wash three times, and finally vacuum-dried at room temperature for 24 h to obtain a white solid product [VBTEA]Cl with a yield of 85%.

Embodiment 2

[0036] [VBTEA] PF 6 Synthesis. Add 4.311g of [VBTEA]Cl and 3.502g of potassium hexafluorophosphate into a 100mL single-necked round-bottomed flask, then add 0.051g of 2,6-di-tert-butyl-4-methylphenol and 15mL of anhydrous acetonitrile at 25 The reaction was stirred at ℃ for 48 hours. After the reaction, the precipitate formed was removed by filtration, the filtrate was poured into ether and washed 3 times, and the obtained solid precipitate was vacuum-dried at room temperature for 24 hours to obtain the white solid product [VBTEA]PF 6 , the yield was 90%.

Embodiment 3

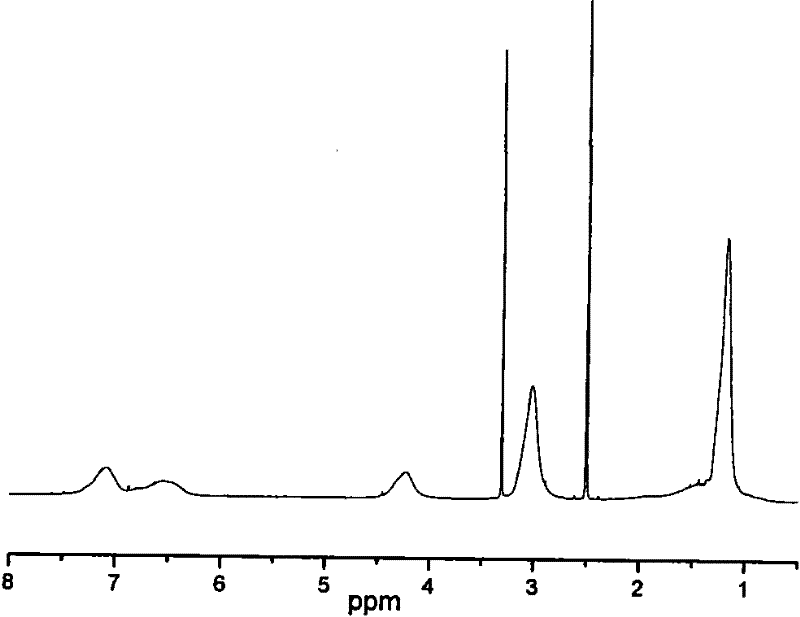

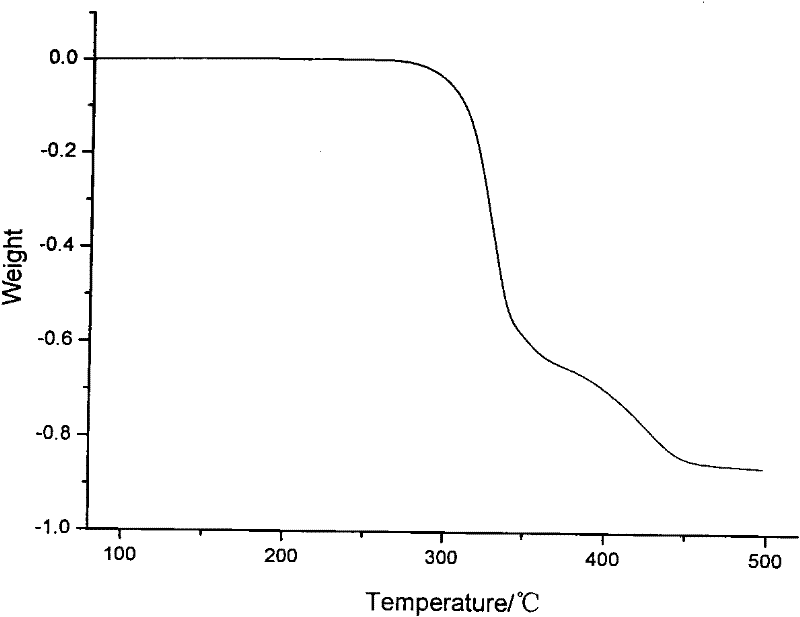

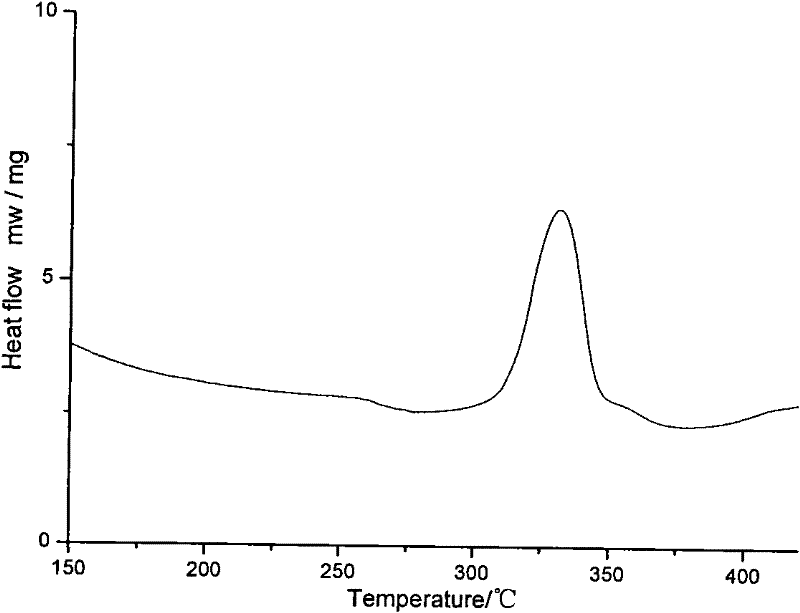

[0038] P[VBTEA]PF 6 Synthesis. Under a nitrogen atmosphere, 10mL DMF was added to a 50mL reaction eggplant-shaped flask, and then 3.002g [VBTEA]PF 6 Dissolve in DMF, then add 0.030g AIBN, then raise the temperature to 60°C, and react at constant temperature for 6h. After the reaction, pour the mixed solution into a large amount of methanol to precipitate, and the obtained solid is vacuum-dried at 100°C for 24h to obtain white final Product P[VBTEA]PF 6 , the yield was 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com