A method and device for efficient utilization of all components of chlorine-containing plastic waste

A waste and resource recycling technology, applied in the field of solid waste resource utilization, can solve the problems of small demand for hydrochloric acid, low price, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

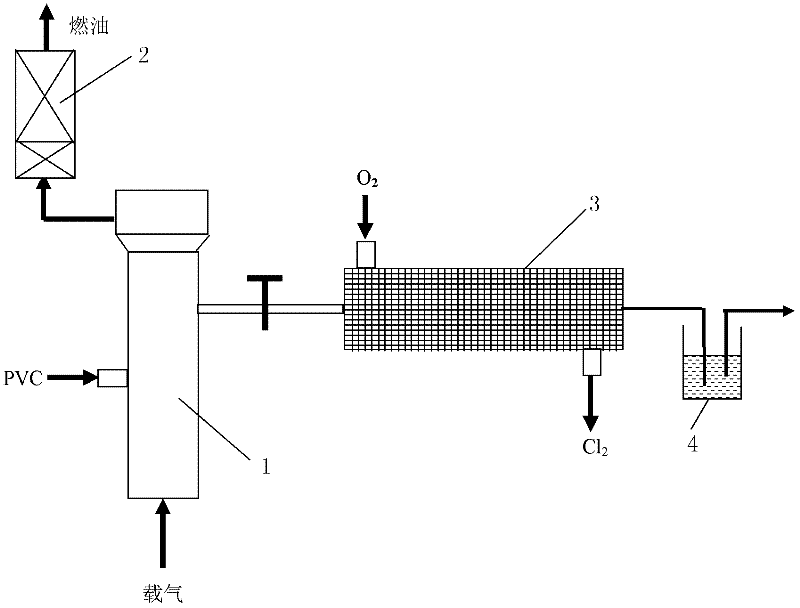

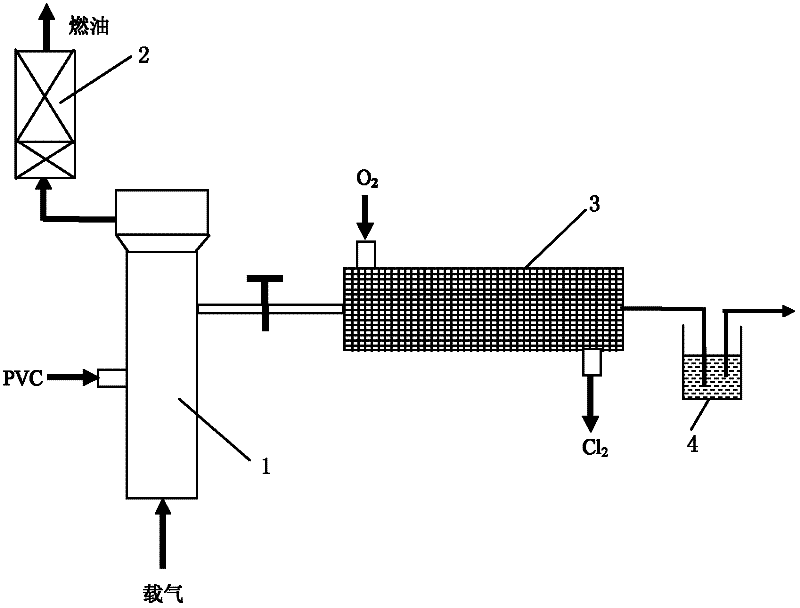

Method used

Image

Examples

Embodiment 1

[0039] Monolithic catalyst preparation:

[0040] (1) 12.4g RuCl 3 ·3H 2 Dissolve O in 96mL of ethylene glycol, add 5.4g of SBA-15, then slowly heat to 140°C, and dropwise add 220mL of 1mol L -1 K 2 CO 3 The aqueous solution was stirred with nitrogen for 5h, transferred to an autoclave at 100°C, crystallized for 10h, filtered, dried, and calcined at 260°C to obtain about 7.7g of 10% RuO 2 / SBA-15;

[0041] (2) RuO 2 / SBA-15 is ground into powder, adding γ-Al 2 o 3 Sol (containing γ-Al 2 o 3 about 6g) and 10mL 1mol L -1 HNO 3 , with magnetic stirring for 5h, the RuO 2 Content is the active slurry of 5wt%;

[0042] (3) Dip the treated FeCrAl alloy into γ-Al 2 o 3 Sol (containing γ-Al 2 o 3 About 6g), after 5 minutes, it rises vertically slowly, blows off the excess sol with air, rotates and dries horizontally, bakes at 500°C for 2 hours, and repeats the operation steps three times to obtain γ-Al 2 o 3 The content is about 8wt% coated with γ-Al 2 o 3 FeCrAl al...

Embodiment 2

[0045] The RuCl in the embodiment 1 monolithic catalyst preparation step (1) 3 ·3H 2 O is replaced by CuCl with the same number of moles 2 Solution, the temperature of the autoclave is changed to 140°C, the crystallization time is changed to 12h, the roasting temperature is changed to 320°C, and SBA-15 is replaced by rutile TiO in step (2). 2 , the calcination temperature in step (3) is changed to 600°C, and other conditions remain unchanged, CuO / TiO2 / FeCrAl. It is placed in a fixed bed as a monolithic catalyst. The chlorine-containing plastic waste is a mixture of PVC, PP and PE, wherein the mass percentage of PVC is 30%, the temperature of the cracking fluidized bed is kept at 300°C, the temperature of the integral catalyst fixed bed is kept at 190°C, and the cracking fluidized bed It is in communication with the monolithic catalyst fixed bed. After 20 minutes, cut off the connection between the two beds, raise the temperature of the cracking fluidized bed to 450°C, and...

Embodiment 3

[0047] The autoclave temperature in the monolithic catalyst preparation step (1) of Example 1 was changed to 140°C, the crystallization time was changed to 12h, the roasting temperature was changed to 320°C, and SBA-15 was replaced by MCM-41 in step (2), The calcination temperature in step (3) is changed to 600°C, the FeCrAl alloy is replaced by cordierite, and other conditions remain unchanged, and RuO 2 / MCM-41 / cordierite. Chlorine-containing plastic waste is a mixture of PVC, PP and PE, wherein the mass percentage of PVC is 50%, the temperature of the cracking fluidized bed is kept at 300°C, the temperature of the monolithic catalyst fixed bed is kept at 200°C, and the cracking fluidized bed It is in communication with the monolithic catalyst fixed bed. After 20 minutes, cut off the connection between the two beds, raise the temperature of the cracking fluidized bed to 460°C, and crack other components in the plastic. Raise the temperature of the monolithic catalyst fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com