A kind of coating liquid composition of erythromycin enteric-coated pellets

An enteric-coated pellet and enteric-coated technology are applied in the preparation of the erythromycin enteric-coated pellets, the preparation of the boiling-coating granulator, and the field of erythromycin enteric-coated pellets, which can solve the problem of less equipment and granules. Small diameter, small particle size and other problems, to achieve the effect of reducing production cost, high production efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

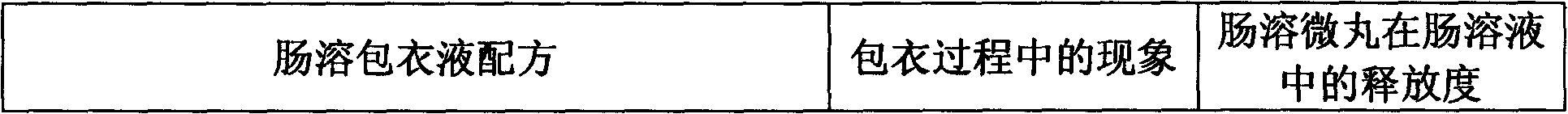

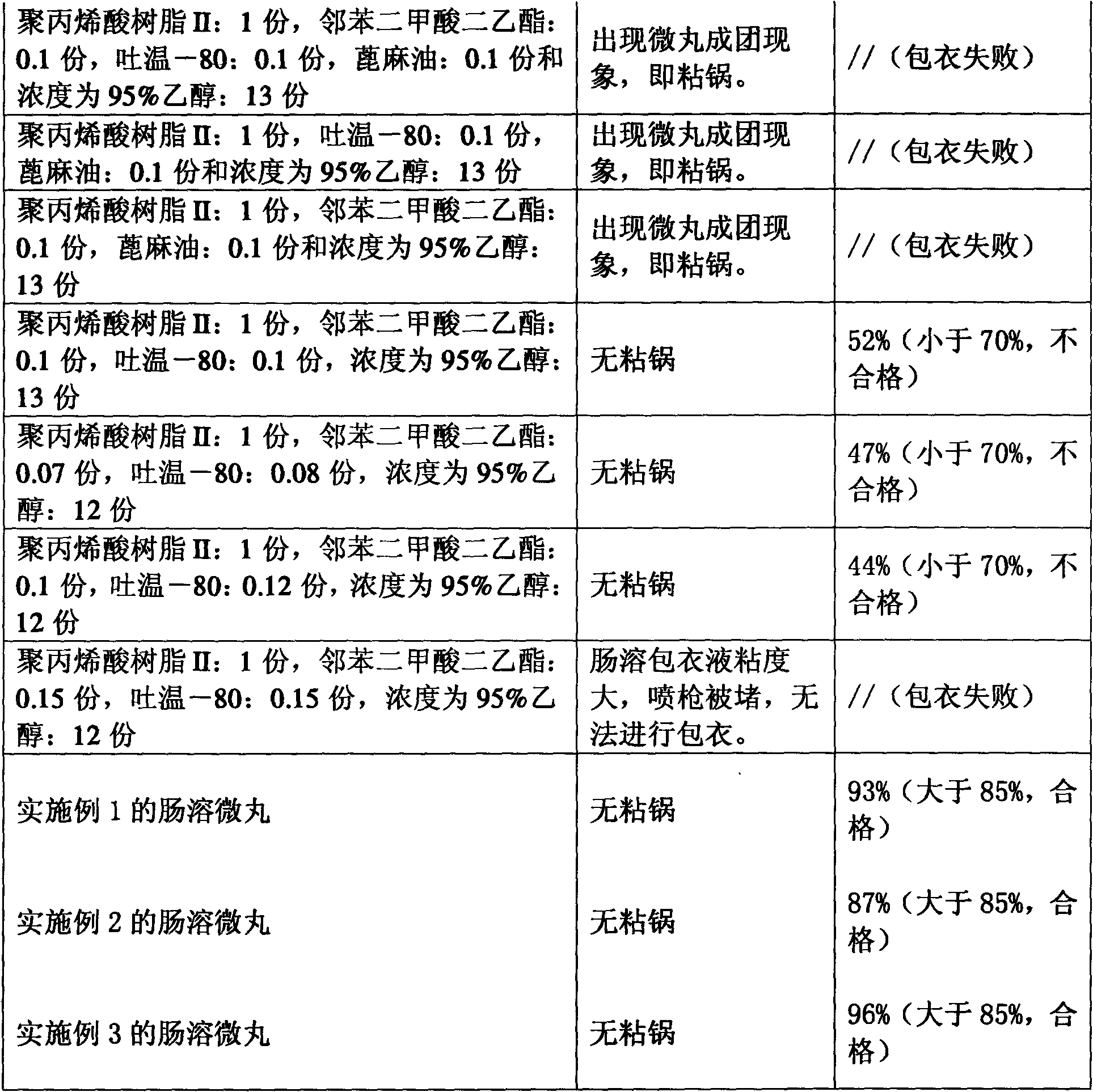

[0032] Example 1 Preparation Example 1 of Enteric-coated Pellets

[0033] (1) Put 1 part of polyacrylic acid resin II in 15 parts of 95% (v / v) ethanol, after the polyacrylic resin is fully dissolved, add 0.15 parts of diethyl phthalate and 0.15 parts of Tween-800, and stir After uniformity, the enteric coating solution is obtained and set aside.

[0034] (2) Mix 1 part of erythromycin and 0.2 part of dextrin, add 0.15 part of 4% (w / w) hydroxypropyl methylcellulose (HPMC) solution, and mix in CH-150 tank mixer (available from (Jiangyin Zhongrui Drying Equipment Co., Ltd.) was fully mixed, and then extruded with a TC-42 extruder (available from Guangdong Henglian Food Machinery Co., Ltd.) and then extruded with a QZL-550 spheronizer (available from Changzhou Jiafa). Granulating Drying Equipment Co., Ltd.) into granules, and finally dried with a CT-C-III hot air circulation oven (available from Jiangyin Zhongrui Drying Equipment Co., Ltd.) to make pellets with an average particl...

Embodiment 2

[0037] Example 2 Preparation Example 2 of Enteric-coated Pellets

[0038] (1) Put 1 part of polyacrylic resin II in 18 parts of 95% (v / v) ethanol, after the polyacrylic resin is fully dissolved, add 0.2 parts of diethyl phthalate and 0.2 parts of Tween-800, and stir After uniformity, the enteric coating solution is obtained and set aside.

[0039] (2) Mix 1 part of erythromycin and 0.2 part of dextrin, add 0.15 part of 4% (w / w) hydroxypropyl methylcellulose solution, mix well in a CH-150 tank mixer, and then use Extruded by TC-42 extruder and spheronized into particles by QZL-550 spheronizer, and finally dried by CT-C-III hot air circulation oven to make pellets with an average particle size of 1.0 mm for future use.

[0040] (3) Place the pellets prepared in step (2) in a BF120B boiling coating machine, adjust to stabilize the inlet air temperature at 60°C and the outlet air temperature at 40°C, and put the enteric-coated pellets prepared in step (2) into The coating soluti...

Embodiment 3

[0042] Example 3 Preparation Example 3 of Enteric-coated Pellets

[0043] (1) Put 1 part of polyacrylic resin II in 22 parts of 95% (v / v) ethanol, after the polyacrylic resin is fully dissolved, add 0.25 parts of diethyl phthalate and 0.25 parts of Tween-800, and stir After uniformity, the enteric coating solution is obtained and set aside.

[0044] (2) Mix 1 part of erythromycin and 0.2 part of dextrin, add 0.15 part of 4% (w / w) hydroxypropyl methylcellulose solution, mix well in a CH-150 tank mixer, and then use Extruded by TC-42 extruder and spheronized into granules by QZL-550 spheronizer, finally dried by CT-C-III hot air circulation oven to make pellets with an average particle size of 1.2 mm for future use.

[0045] (3) Place the pellets prepared in step (2) in a BF120B boiling coating machine, adjust to stabilize the inlet air temperature at 60°C and the outlet air temperature at 40°C, and put the enteric-coated pellets prepared in step (2) into The coating solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com