Catalyst for preparing hexafluoroisopropanol by gas-phase catalytic hydrogenation of hexafluoroacetone hydrate, its preparation method and application

A technology for hydration of hexafluoroacetone and hexafluoroisopropanol, which is used in physical/chemical process catalysts, hydroxyl compound preparation, metal/metal oxide/metal hydroxide catalysts, etc. and other problems to achieve the effect of improving stability, reducing load and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The pretreatment of embodiment 1 carrier activated carbon

[0032] Configure 500ml of nitric acid solution with a mass percentage of 30% in proportion, weigh 150g of coconut shell activated carbon and add it to the nitric acid solution, heat up to 90°C, stir and reflux for 2.0h, cool down to room temperature, wash with deionized water until the pH value of the eluate Constant, vacuum drying at 100°C for 4.0h for later use.

Embodiment 2

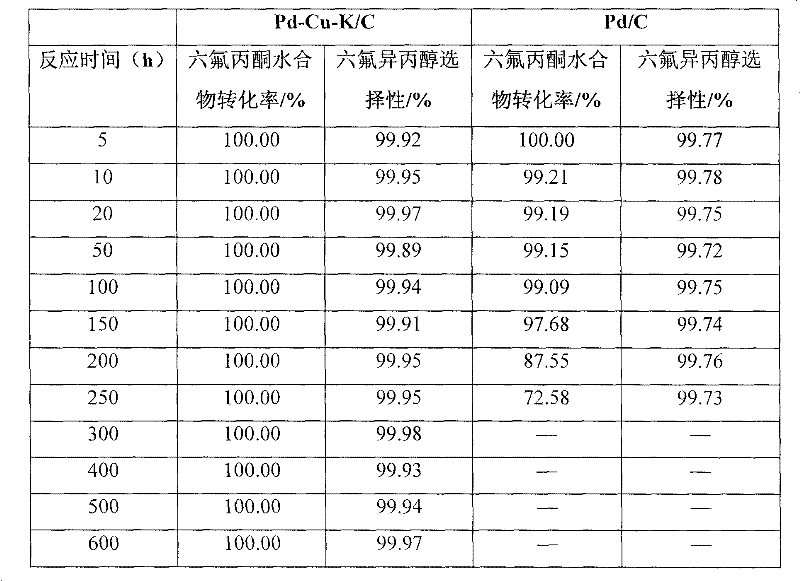

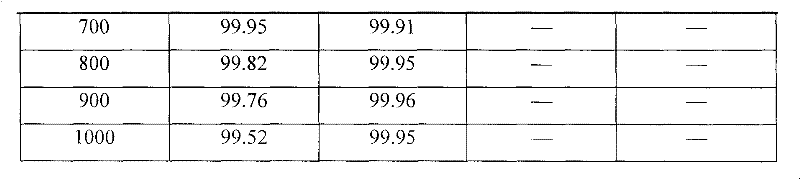

[0033] Embodiment 2Pd-Cu-K / C catalyst preparation and activity evaluation

[0034]Take by weighing 0.1g KCl, add 10g deionized water to dissolve, add the activated carbon carrier that 10g embodiment 1 is processed in the solution, impregnate 10.0h, 90 ℃ of vacuum drying 5.0h, then weigh 6.0g chloropalladic acid aqueous solution (palladium's Mass percent content 2.55%), 1.35gCuCl 2 2H 2 O, add 4.0g deionized water to make a mixed solution, add activated carbon impregnated with K to the solution, impregnate for 10.0h, vacuum dry at 90°C for 5.0h, and then roast at 500°C for 3.0h for later use.

[0035] Weigh 3.0ml of the prepared catalyst sample and load it into a fixed-bed reactor, inject a hydrogen-nitrogen mixed gas for temperature reduction, the hydrogen ratio is 30%, the reduction temperature is 250°C, the reduction time is 2h, and the reducing gas space velocity is 500h -1 . After the reduction, the gas-phase catalytic hydrogenation reaction is carried out, the vaporiza...

Embodiment 3

[0036] Embodiment 3Pd-Cu-La / C catalyst preparation and activity evaluation

[0037] Weigh 0.31gLa(NO 3 ) 3 ·6H 2 O, 0.38gCu(NO 3 ) 3 ·3H 2 O, add 10 g of deionized water to dissolve, add the activated carbon carrier treated in Example 1 to the mixed solution, impregnate for 12.0 h, and vacuum dry at 90° C. for 5.0 h. Then take by weighing 8.0g chloropalladic acid aqueous solution (the mass percent composition of palladium 2.55%), add 2.0g deionized water and make solution, add the gac that has impregnated La before in the solution, Cu, dipping 24.0h, 90 ℃ Vacuum-dry for 5.0h, and then bake at 300°C for 5.0h for later use.

[0038] Catalyst reduction and activity evaluation methods are the same as in Example 2, wherein the proportion of hydrogen in the reducing gas is 10%, the reduction temperature is 180°C, the reduction time is 3h, and the space velocity of the reducing gas is 800h -1 . After the reduction, the gas-phase catalytic hydrogenation reaction is carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com