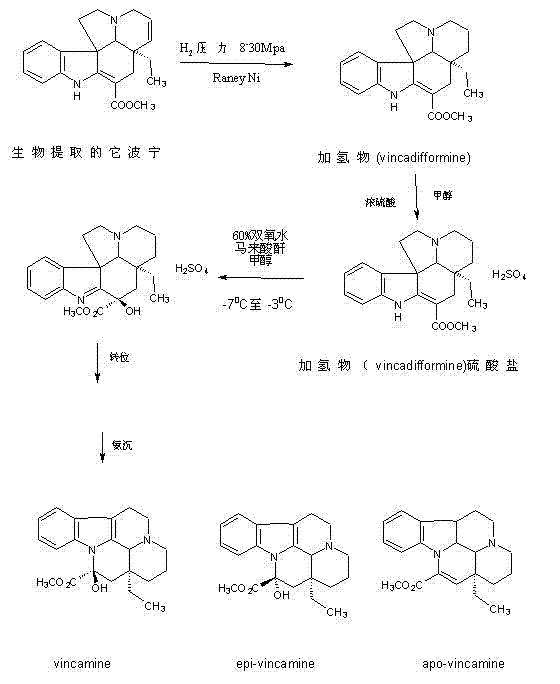

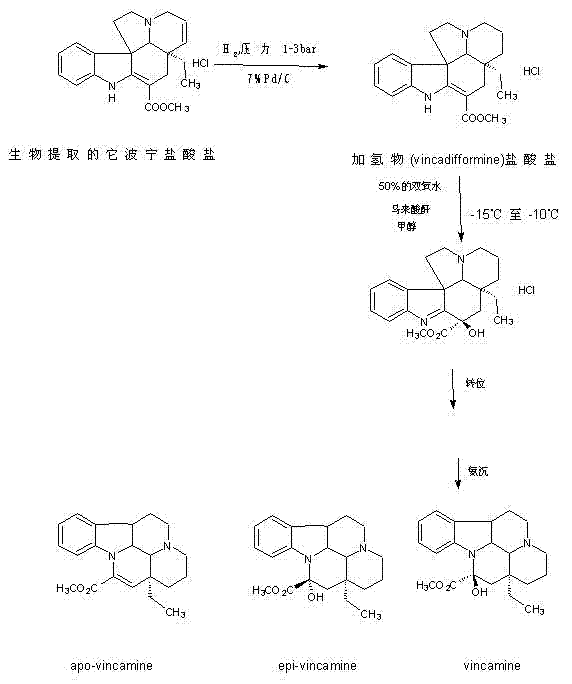

Process for preparing vincamine by semisynthetic method

A preparation process, the technology of vincamine, applied in the field of chemical drug synthesis process, can solve the problems of reducing the ratio of isomer formation, easy loss of activity, easy to burn, etc., to achieve the effect of reducing pressure, reducing cost, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of Tabonin Hydrogenate Hydrochloride:

[0048] In a 100L sealed enamel reaction kettle, add 50Kg of industrial methanol, start stirring, and then add 5Kg (13.42mol) of Tabonin hydrochloride, and add 1Kg of Tabonin hydrochloride quickly (the quality of Tabonin hydrochloride is 20 %) of pure Pd with a mass percentage content of 7% Pd / C (manufactured by Shaanxi Ruike New Material Co., Ltd.), then seal the lid of the kettle, replace it with 99.9% nitrogen three times, and then use hydrogen (purity ≥ 99.5 %) of hydrogen replacement three times, pass hydrogen until the pressure is 0.25Mpa, slowly raise the temperature to 25°C, and stir the reaction at a speed of 100r / min. After reacting for 10 hours, take a sample from the sampling hole and analyze it with a TLC spot plate. The volume of the developer The ratio is ethyl acetate:petroleum ether=2:3, the dosage is 5ml, under the ultraviolet light, observe with a wavelength of 254nm, until there is no raw material...

Embodiment 2

[0061] 1. Preparation of Tabonin Hydrogenate Hydrochloride:

[0062] In a 100L stainless steel reaction kettle, add 50Kg of industrial methanol, start stirring, then add 5Kg (13.42mol) of Tabonin hydrochloride, and quickly add 0.5Kg (10% of the mass of Tabonin hydrochloride) ) of the newly prepared 7% Pd / C, then add 1.5Kg wet weight in Example 1 to collect and seal the recovered Pd / C, seal the lid of the kettle, replace it with high-purity nitrogen three times, and then use hydrogen (purity ≥ 99.5% ) after three times of hydrogen replacement, the pressure of the pressure gauge on the reaction kettle was 0.35 Mpa with hydrogen, and the temperature was slowly raised to 30°C, and the reaction was stirred. After 15 hours of reaction, samples were taken from the sampling hole and analyzed by TLC spot plate. The developing agent was acetic acid Ethyl ester: Petroleum ether = 2:3, under the ultraviolet lamp, observe with a wavelength of 254nm, until there is no raw material it bonin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com