Manchuronol sulfide electrocatalyst with high catalytic activity and stability, preparation method of Manchuronol sulfide electrocatalyst and application of Manchuronol sulfide electrocatalyst in electrolyzed water

A technology with high catalytic activity and sulfide electricity, applied in the field of electrochemistry, to achieve the effects of wide sources, low overpotential, and ultra-high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

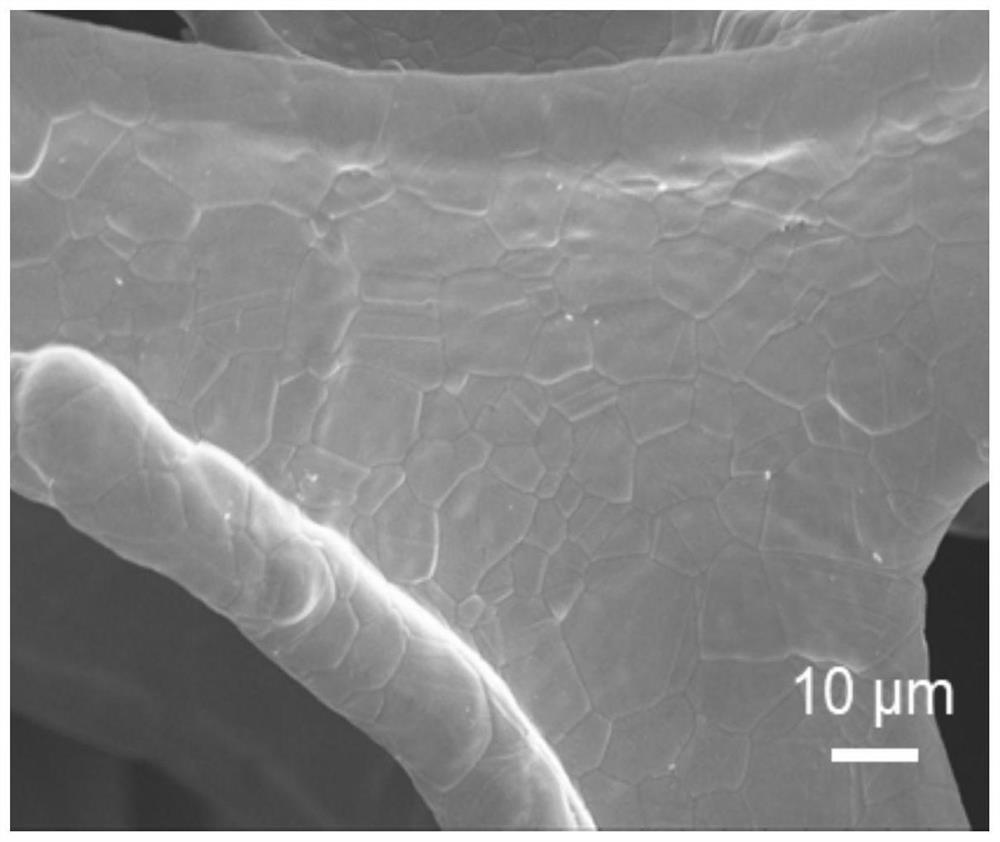

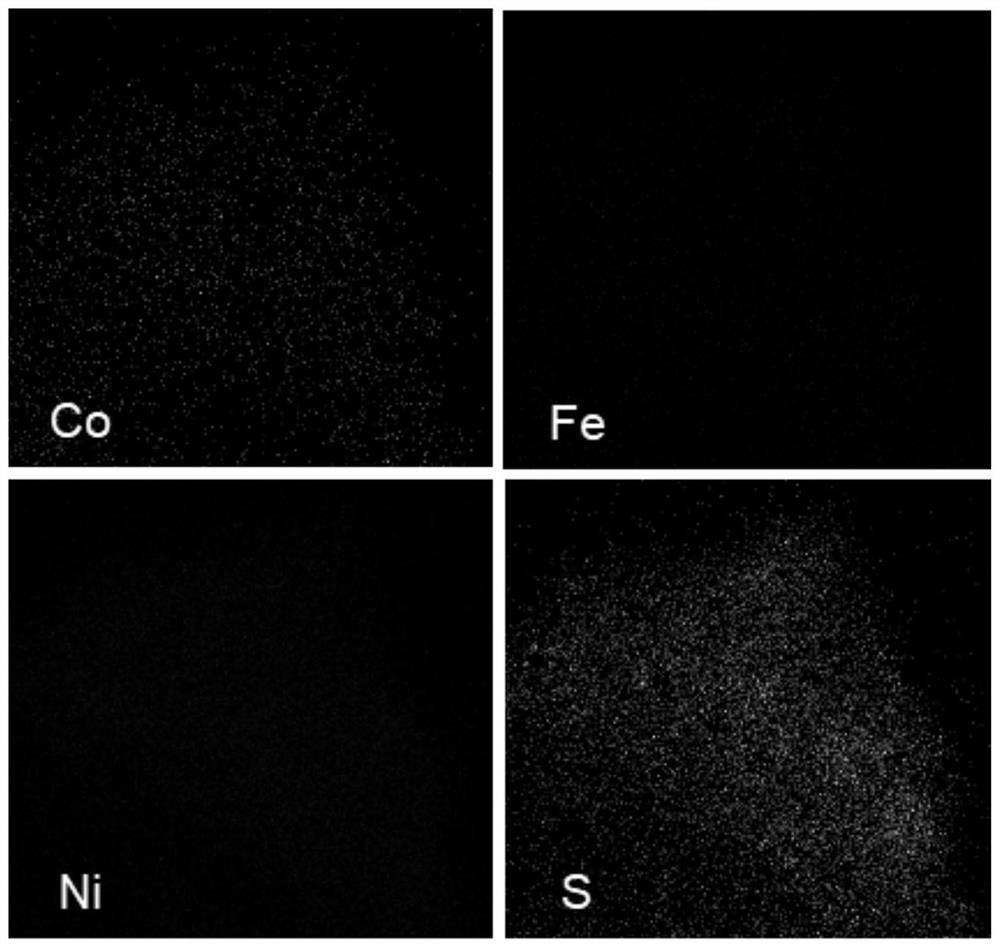

[0049] A preparation method of a Makino ore sulfide (FeCoNiS) electrocatalyst with high catalytic activity and stability, comprising the following steps:

[0050] (1) Cut the selected nickel foam into 1*3cm 2 size, use acetone, 2mol / L hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut nickel foam for 30 minutes in turn. After cleaning, put it into a vacuum drying box at 60 °C for vacuum drying for 24 hours to obtain the pretreated foam. Nickel; in a three-electrode system with pretreated nickel foam as the working electrode, platinum sheet as the counter electrode, and silver / silver chloride electrode as the reference electrode, Zn(NO 3 ) 2 and NH 4 NO 3 The mixed solution is an electrodeposition solution, at a temperature of 80 °C and 2 mA / cm 2 Electrodeposition was carried out at a constant current density of 90 min; after the reaction was completed, the nickel foam deposited with zinc oxide nanorods was washed with deionized water and anhydr...

Embodiment 2

[0064] A preparation method of a Makino ore sulfide (FeCoNiS) electrocatalyst with high catalytic activity and stability, comprising the following steps:

[0065] (1) Cut the selected nickel foam into 1*3cm 2 size, use acetone, 2mol / L hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut nickel foam for 30 minutes in turn. After cleaning, put it into a vacuum drying box at 60 °C for vacuum drying for 24 hours to obtain the pretreated foam. Nickel; in a three-electrode system with pretreated nickel foam as the working electrode, platinum sheet as the counter electrode, and silver / silver chloride electrode as the reference electrode, Zn(NO 3 ) 2 and NH 4 NO 3 The mixed solution is an electrodeposition solution, at a temperature of 80 °C and 2 mA / cm 2 Electrodeposition was carried out at a constant current density of 90 min; after the reaction was completed, the nickel foam deposited with ZnO nanorods was washed with deionized water and anhydrous eth...

Embodiment 3

[0072] A preparation method of a Makino ore sulfide (FeCoNiS) electrocatalyst with high catalytic activity and stability, comprising the following steps:

[0073] (1) Cut the selected nickel foam into 1*3cm 2 size, use acetone, 2mol / L hydrochloric acid, deionized water, and ethanol to ultrasonically clean the cut nickel foam for 30 minutes in turn. After cleaning, put it into a vacuum drying box at 60 °C for vacuum drying for 24 hours to obtain the pretreated foam. Nickel; in a three-electrode system with pretreated nickel foam as the working electrode, platinum sheet as the counter electrode, and silver / silver chloride electrode as the reference electrode, Zn(NO 3 ) 2 and NH 4 NO 3 The mixed solution is an electrodeposition solution, at a temperature of 80 °C and 2 mA / cm 2 Electrodeposition was carried out at a constant current density of 90 min; after the reaction was completed, the nickel foam deposited with ZnO nanorods was washed with deionized water and anhydrous eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com