Gadolinium thulium vanadate/borate blue light-emitting material and preparation method thereof

A technology of blue luminescent material and vanadium boric acid, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of reduced luminous intensity, irregular shape, and affecting luminous intensity, and achieves improved luminous intensity, simple preparation method, The effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

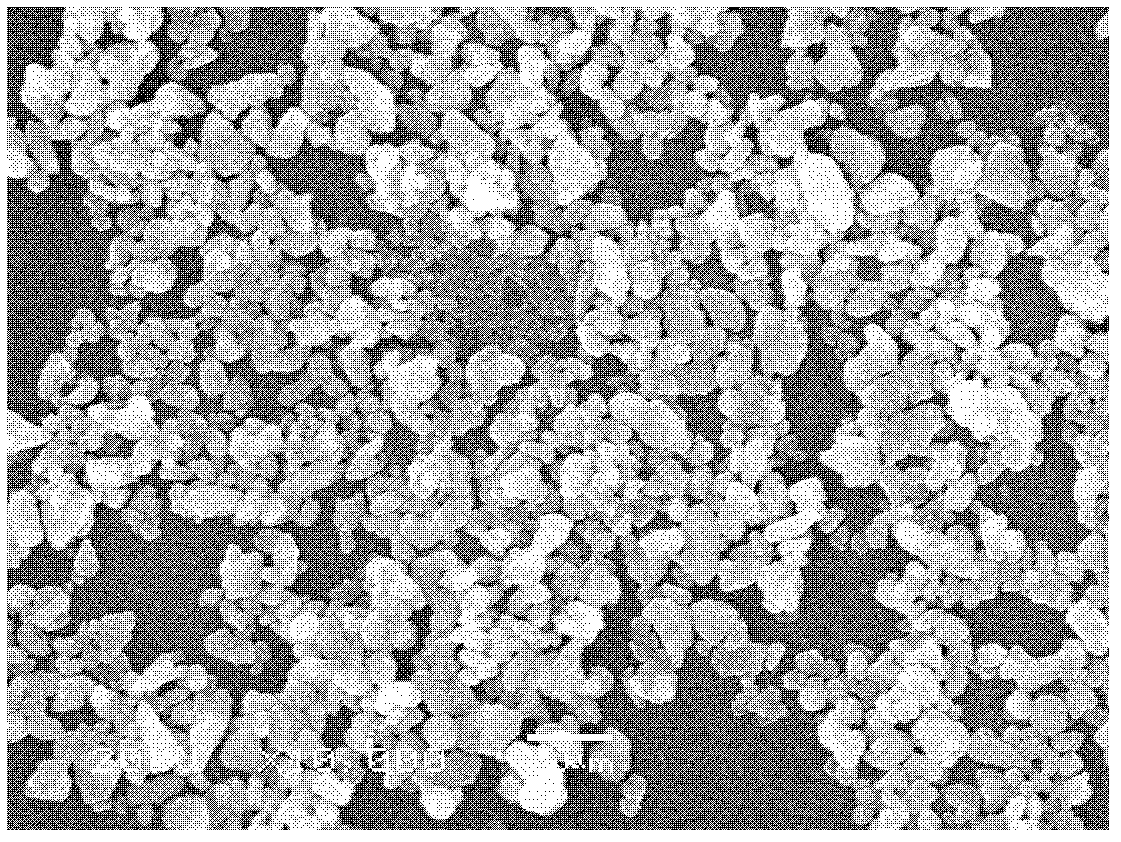

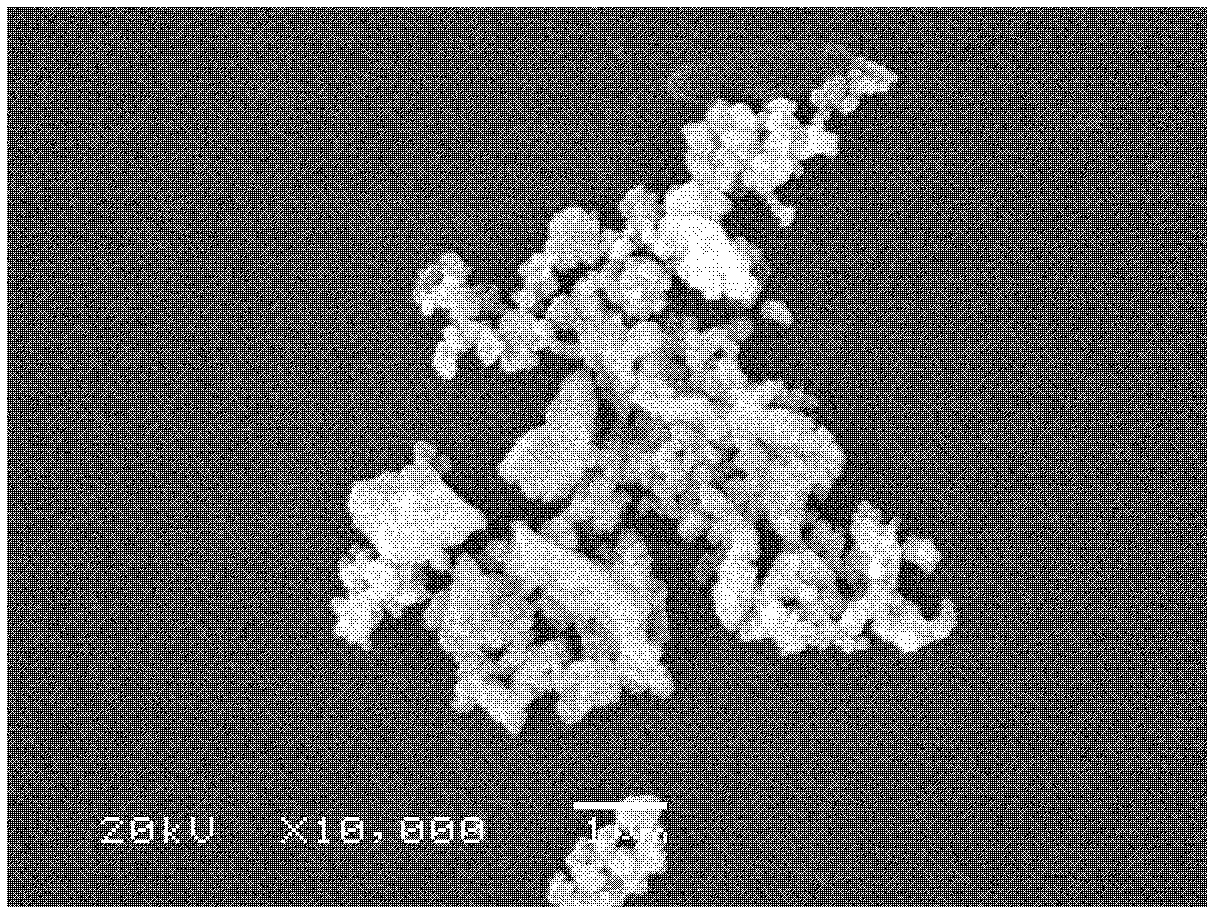

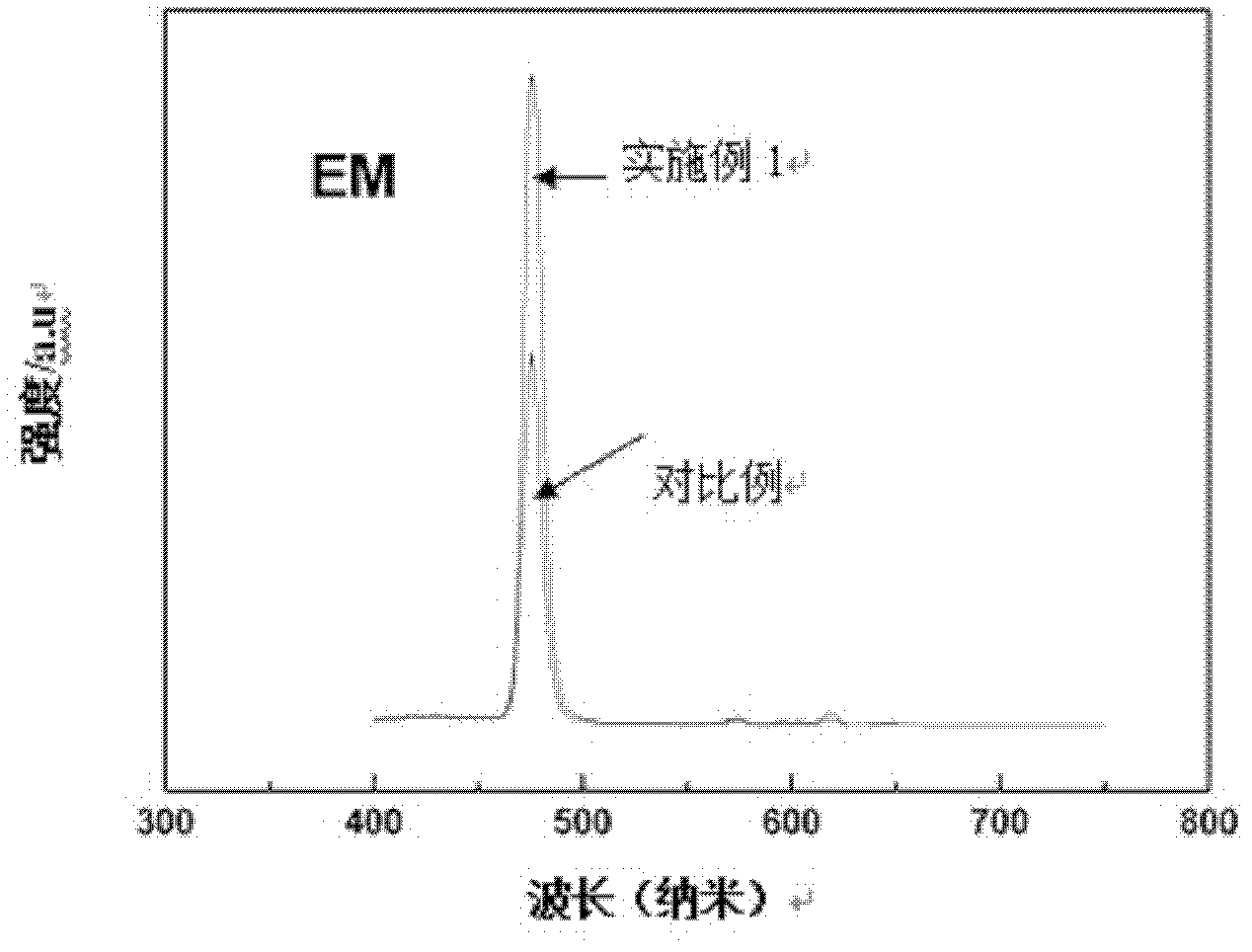

Embodiment 1

[0026] In this embodiment, the chemical composition of the prepared gadolinium thulium vanadium borate blue luminescent material is Gd 0.98 (VO 4 ) 0.6 (BO 3 ) 0.4 :Tm 0.02 , The process steps are as follows:

[0027] (1) Preparation of the precursor

[0028] Take NH 4 VO 3 (Ammonia metavanadate), Gd(NO 3 ) 3 .6H 2 O (Gadolinium Nitrate), Tm (NO 3 ) 3 .5H 2 O (thulium nitrate), H 3 BO 3 (Boric acid) and citric acid as raw materials, and measure NH according to the chemical composition of the prepared vanadium borate gadolinium thulium blue luminescent material 4 VO 3 , Gd(NO 3 ) 3 .6H 2 O, Tm(NO 3 ) 3 .5H 2 O and H 3 BO 3 , Measure citric acid according to the molar ratio of gadolinium + thulium to citric acid of 1:6, the operation steps are:

[0029] ① NH measured according to the above ratio 4 VO 3 And H 3 BO 3 Put it into the container and add deionized water, the amount of deionized water added can dissolve NH 4 VO 3 And H 3 BO 3 As a limit, stir under normal pressure and 50℃ unti...

Embodiment 2

[0051] In this embodiment, the chemical composition of the prepared gadolinium thulium vanadium borate blue luminescent material is Gd 0.99 (VO 4 ) 0.6 (BO 3 ) 0.4 : Tm 0.01 , The process steps are as follows:

[0052] (1) Preparation of the precursor

[0053] Take NH 4 VO 3 (Ammonia metavanadate), Gd(NO 3 ) 3 .6H 2 O (Gadolinium Nitrate), Tm (NO 3 ) 3 .5H 2 O (thulium nitrate), H 3 BO 3 (Boric acid) and citric acid as raw materials, and measure NH according to the chemical composition of the prepared vanadium borate gadolinium thulium blue luminescent material 4 VO 3 , Gd(NO 3 ) 3 .6H 2 O, Tm(NO 3 ) 3 .5H 2 O and H 3 BO 3 , Measure citric acid according to the molar ratio of gadolinium + thulium to citric acid of 1:3, the operation steps are:

[0054] ① NH measured according to the above ratio 4 VO 3 And H 3 BO 3 Put it into the container and add deionized water. The amount of deionized water added is limited to dissolving ammonia metavanadate and boric acid. Stir at normal pressure ...

Embodiment 3

[0062] In this embodiment, the chemical composition of the prepared gadolinium thulium vanadium borate blue luminescent material is Gd 0.97 (VO 4 ) 0.1 (BO 3 ) 0.9 :Tm 0.03 , The process steps are as follows:

[0063] (1) Preparation of the precursor

[0064] Take NH 4 VO 3 (Ammonia metavanadate), Gd(NO 3 ) 3 .6H 2 O (Gadolinium Nitrate), Tm (NO 3 ) 3 .5H 2 O (thulium nitrate), H 3 BO 3 (Boric acid) and citric acid as raw materials, and measure NH according to the chemical composition of the prepared vanadium borate gadolinium thulium blue luminescent material 4 VO 3 , Gd(NO 3 ) 3 .6H 2 O, Tm(NO 3 ) 3 .5H 2 O and H 3 BO 3 , Measure citric acid according to the molar ratio of gadolinium + thulium to citric acid of 1:4, the operation steps are:

[0065] ① NH measured according to the above ratio 4 VO 3 And H 3 BO 3 Put it into the container and add deionized water, the amount of deionized water added can dissolve NH 4 VO 3 And H 3 BO 3 As a limit, stir under normal pressure and 60℃ unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com