High-toughness single-phase solid solution magnesium rare earth-based alloy at room temperature and preparation method thereof

A solid solution, rare earth-based technology, applied in the field of magnesium alloy and its preparation, can solve the problems of obvious hot cracking tendency, decreased alloy corrosion resistance, narrow processing temperature range, etc., achieve outstanding mechanical properties and processing performance, and improve deformation processing performance. , The effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

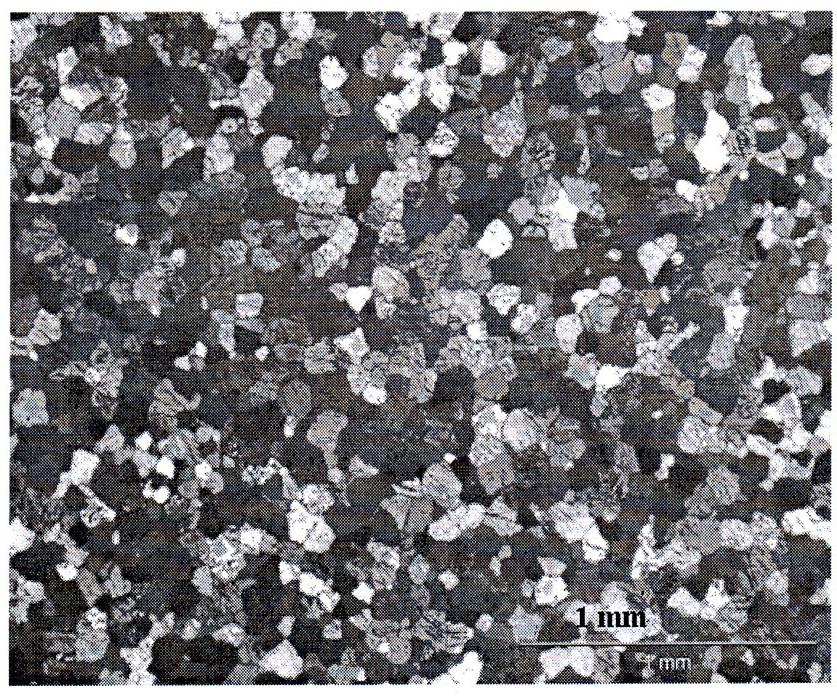

[0019] According to the composition of Mg-0.5RE-1.5Sc-0.01Ag (wt.%), the mass ratio of raw materials is carried out, magnesium is the balance, and the mass fraction ratio of Gd, Y, Dy, Er and Tm in RE is equal, and the ratio of all raw materials The mass purity is: 99.5% Mg ingot, 99% Mg-20wt.%RE master alloy ingot, 99% Sc ingot and 99.99% Ag ingot. First remove the surface scale of the above-mentioned metal ingots and intermediate alloy ingots. The intermediate alloy ingots must be fully preheated at 200°C, and then the metal Mg ingots, Mg-RE intermediate alloy ingots, Sc ingots and Ag ingots are added to the automatic ingot in sequence. In a temperature-controlled resistance furnace, the melting temperature is 700°C, protected by a 1:19 mixture of sulfur hexafluoride and argon, and stirring for 10 minutes each time a raw material is added; after all the raw materials are added, stir for another 30 minutes; 770°C is poured into the steel mold, and the steel mold should be pre...

Embodiment 2

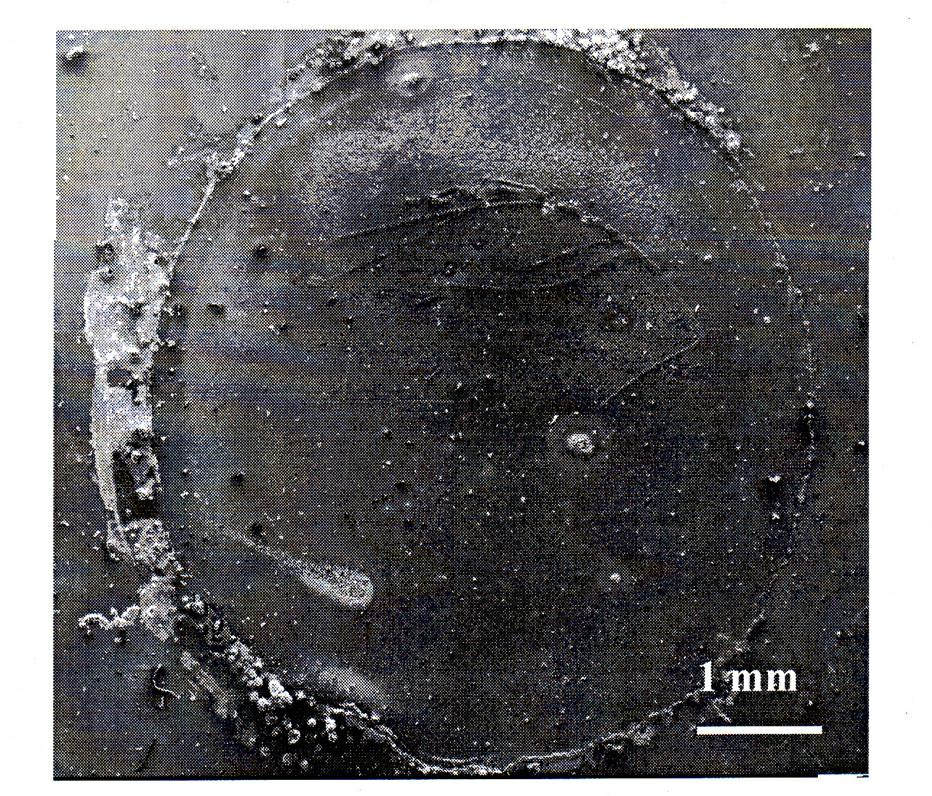

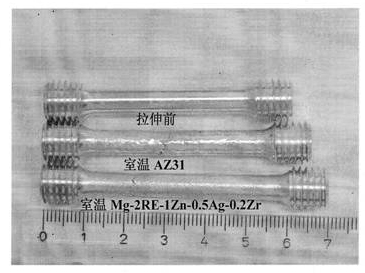

[0021] The mass ratio of raw materials is carried out according to the composition of Mg-2RE-1Zn-0.2Ag-0.2Zr (wt.%), and magnesium is the balance. The mass fraction ratios of Gd, Y and Lu in RE are equal, and the mass purity of all raw materials are: 99.5% Mg ingot, 99% Mg-20wt.%RE master alloy ingot, 99.9% Zn ingot, 99.99% Ag ingot and 99% Mg-33.3wt.%Zr master alloy ingot. First remove the surface scale of the above metal ingots and intermediate alloy ingots. The intermediate alloy ingots must be fully preheated at 400°C, and then the metal Mg ingots, Zn ingots, Mg-RE intermediate alloy ingots, Ag ingots and Mg- Add the Zr master alloy ingot into the automatic temperature control resistance furnace, the melting temperature is 680°C, and use the mixed gas protection of sulfur hexafluoride and argon at 1:19. Each time a raw material is added, stir for 10 minutes; after all the raw materials are added, Stir for another 30 minutes; pour into the steel mold at 650°C, and the stee...

Embodiment 3

[0023] The mass ratio of raw materials is carried out according to the composition of Mg-3RE-0.1Zn-0.05Ag-0.05Zr, and magnesium is the balance. The mass fraction ratio of Gd and Y in RE is equal, and the mass purity of all raw materials are: 99.5% Mg ingot, 99% Mg-20wt.%RE master alloy ingot, 99.9% Zn ingot, 99.99% Ag ingot And 99% Mg-33.3wt.%Zr master alloy ingot. First remove the surface oxide skin of the above-mentioned metal ingots and intermediate alloy ingots. The intermediate alloy ingots must be fully preheated at 250°C, and then the metal Mg ingots, Zn ingots, Mg-RE intermediate alloy ingots, Ag ingots and Mg -Zr master alloy ingots are added to an automatic temperature-controlled resistance furnace with a melting temperature of 750°C, protected by a 1:19 mixture of sulfur hexafluoride and argon, and stirring for 10 minutes each time a raw material is added; after all raw materials are added , and then stirred for 30 minutes; poured into the steel mold at 660°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com