Construction method and use of fumaric acid producing candida glabrata engineering strain

A technology of Torulopsis glabrata and fumaric acid, which is applied in the field of fermentation engineering and can solve problems such as difficulty in dissolving oxygen and increasing the viscosity of fermentation broth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Construction of Toruula glabrata engineering bacteria producing fumaric acid

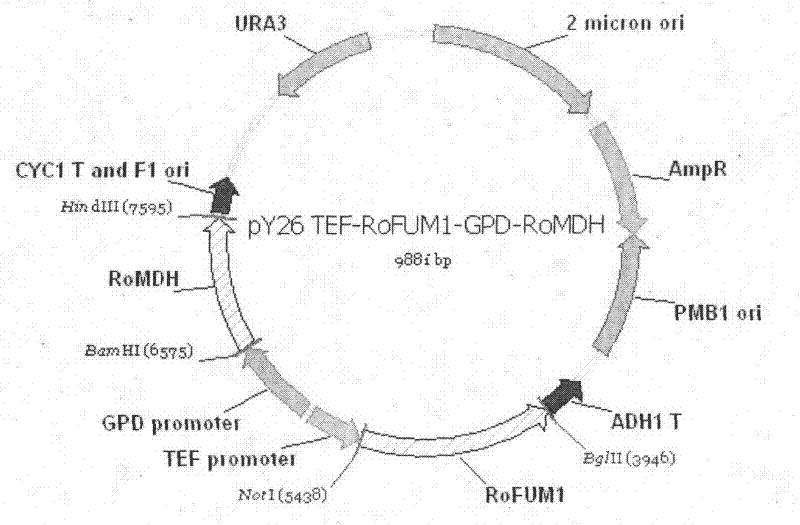

[0025] 1) Construct the free expression vector pY26 TEF-RoFUM1-GPD-RoMDH

[0026] The RoMDH gene that has been connected into the pMD18 T-vector was double-digested, recovered and purified by restriction endonucleases BamHI and HindIII, and connected to the constructed free expression vector pY26 TEF-RoFUM1 (overnight at 16°C) for further construction Episomal expression vector pY26 TEF-RoFUM1-GPD-RoMDH.

[0027] 2) Convert step 1) to connect the product

[0028] After the ligation product was transformed into JM109 competent cells, the LB plate with ampicillin resistance was spread and cultured overnight at 37°C.

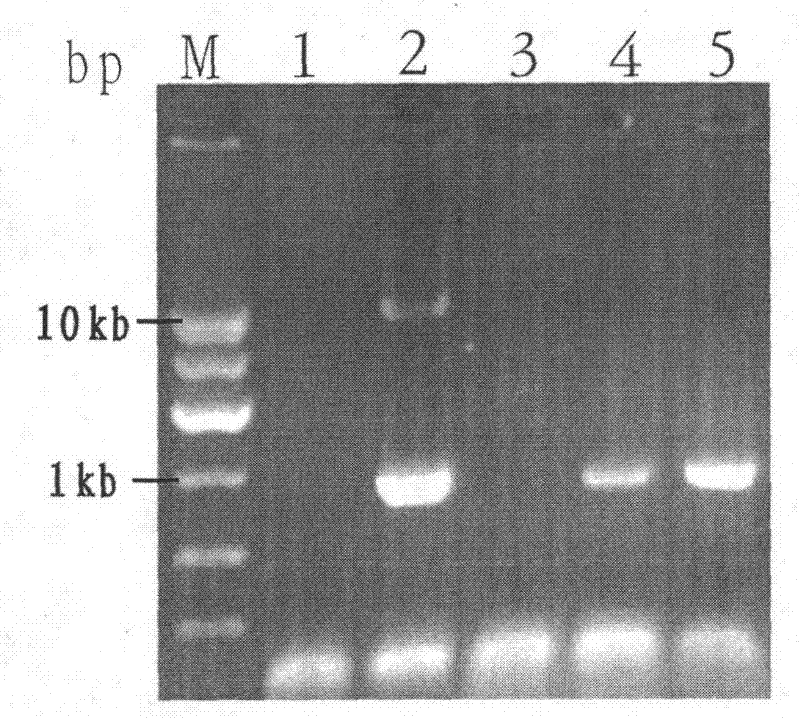

[0029] 3) Extraction plasmid digestion verification

[0030] The transformants were picked to extract plasmids for enzyme digestion verification, and all positive clones were found, indicating that the free expression vector pY26 TEF-RoFUM1-GPD-RoMDH had been successf...

Embodiment 2

[0034] Embodiment 2 utilizes Torulopsis glabrata engineered bacterium to produce fumaric acid

[0035] Pipette 200 μL of Torulopsis glabrata engineering bacteria into the seed medium (20mL / 200mL Erlenmeyer flask) from the glycerol tube, shake the flask at 30°C and 200r / min for 24h, and then inoculum with 10% inoculum (v / v) Access to the fermentation medium. Shake flask fermentation: 50mL of fermentation medium in a 500mL Erlenmeyer flask, the temperature is 30°C, the rotation speed is 200r / min, and the fermentation time is 60h. Adopt high-performance liquid chromatography (HPLC) to measure: the output of fumaric acid is 35mg / L, is 6 times of starting bacterial strain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com