A kind of preparation method of L-malic acid

A technology of malic acid and calcium carbonate, applied in the direction of fermentation, etc., can solve the problems of environmental pollution, large amount of calcium sulfate solid waste, etc., and achieve the effect of reducing production cost, high cost and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of L-malic acid, the steps are as follows:

[0035] 1) Preparation of enzyme solution

[0036] Mix 10g of malonic acid, 15g of diammonium hydrogen citrate, 0.2g of magnesium sulfate, 1g of potassium dihydrogen phosphate, and 25g of corn steep liquor, adjust the pH to 7.25 with 20% sodium hydroxide, add water to 1000ml, and pack to Erlenmeyer flask: Sterilize the Erlenmeyer flask at 121°C for 30 minutes. After the temperature drops, insert Brevibacterium flavum and culture on a shaking table for 32-36 hours to obtain enzyme solution I, whose pH is between 6.5 and 7.5.

[0037] 2) Enzyme conversion

[0038] In a stirred reactor, 232g of fumaric acid and 200g of calcium carbonate were stirred and reacted in an aqueous solution at 80°C for 1 hour, and the pH was controlled between 6.5 and 7.0 during the reaction to generate 308g of calcium fumarate;

[0039] In a conversion tank with stirring, add the enzyme liquid I prepared in step 1) to the obtaine...

Embodiment 2

[0046] A preparation method of L-malic acid, the steps are as follows:

[0047] 1) Preparation of enzyme solution

[0048] Mix 5g of malonic acid, 20g of diammonium hydrogen citrate, 0.1g of magnesium sulfate, 0.5g of potassium dihydrogen phosphate, and 20g of corn steep liquor, adjust the pH to 7.48 with 20% sodium hydroxide, add water to 1000ml, and pack Transfer to the Erlenmeyer flask; sterilize the Erlenmeyer flask at 121°C for 30 minutes. After the temperature drops, insert Brevibacterium flavum and culture on a shaking table for 32-36 hours to obtain enzyme solution II, whose pH is between 7.5 and 8.5.

[0049] 2) Enzyme conversion

[0050] In a stirred reactor, 232g of fumaric acid and 200g of calcium carbonate were stirred and reacted in an aqueous solution at 90°C for 2 hours. During the reaction, the pH was controlled between 7.5 and 8.0 to generate 308g of calcium fumarate;

[0051] In the conversion tank with stirring, add the enzyme solution II prepared in step...

Embodiment 3

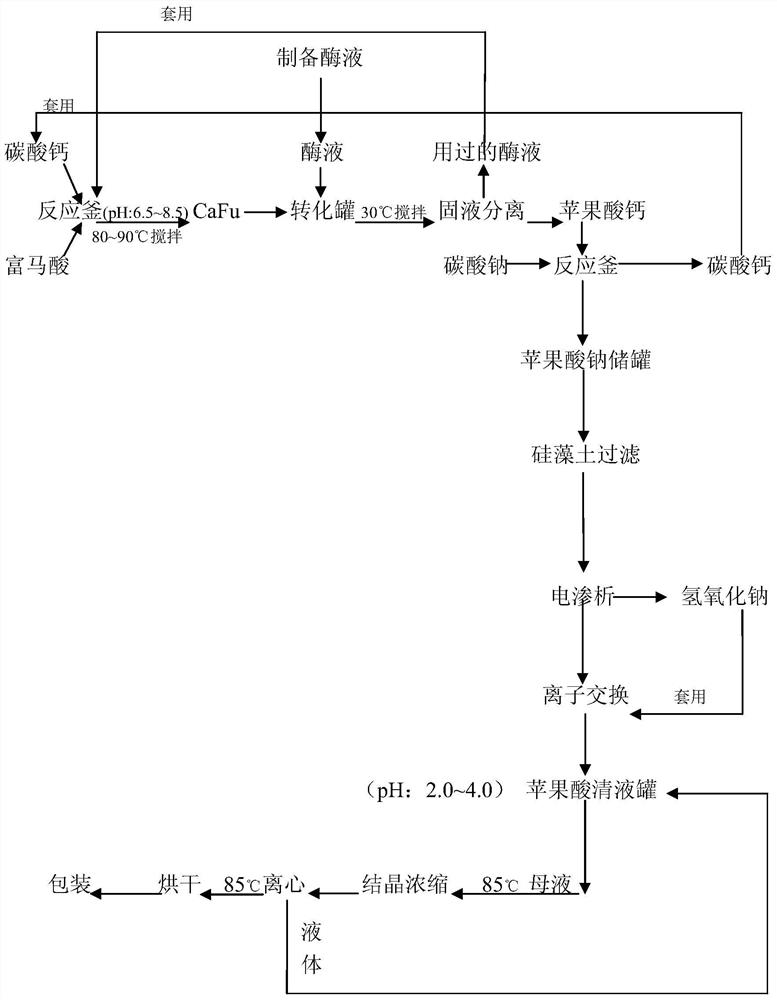

[0058] A kind of preparation method of L-malic acid, such as figure 1 As shown, the steps are as follows:

[0059] 1) Preparation of enzyme solution

[0060] Mix 15g of malonic acid, 10g of diammonium hydrogen citrate, 0.3g of magnesium sulfate, 2g of potassium dihydrogen phosphate, and 30g of corn steep liquor, adjust the pH to 7.45 with 20% sodium hydroxide, add water to 1000ml, and pack to Erlenmeyer flask: Sterilize the Erlenmeyer flask at 121°C for 30 minutes. After the temperature drops, insert Brevibacterium flavum and culture on a shaking table for 32-36 hours to obtain enzyme solution III, whose pH is between 7.5 and 8.5.

[0061] 2) Enzyme conversion

[0062] In a stirred reactor, 464g of fumaric acid and 400g of calcium carbonate were stirred and reacted in an aqueous solution at 85°C for 3 hours, and the pH was controlled between 7.5 and 8.0 during the reaction to generate 616g of calcium fumarate;

[0063] In the conversion tank with stirring, add the enzyme so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com