Waterproof curtain and construction method thereof

A technology of water-stop curtain and cement mixing pile, which is applied in excavation, foundation structure engineering, sheet pile wall, etc., can solve the problems such as very high requirements for concrete ultra-retarding performance, affecting the water-stop effect between piles, and unable to form an occlusal relationship. , to achieve the effect of reducing the impact of the surrounding environment, low cost and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

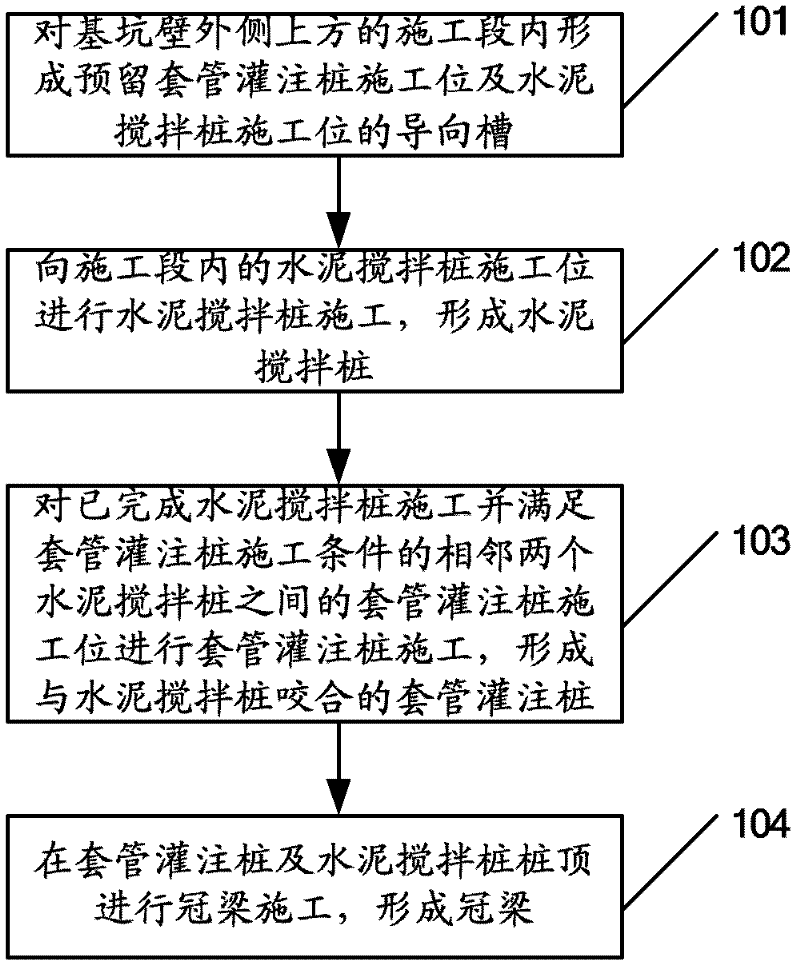

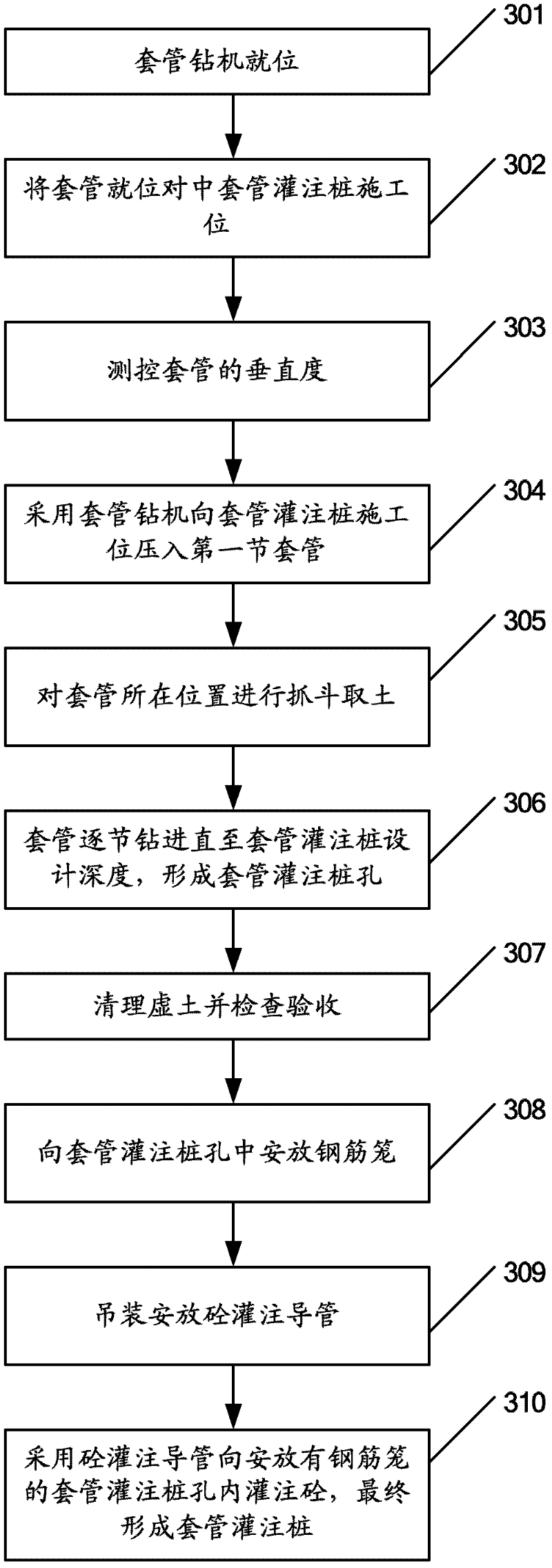

[0022] Such as figure 1 As shown, the construction method of the water-stop curtain of the embodiment of the present invention mainly comprises:

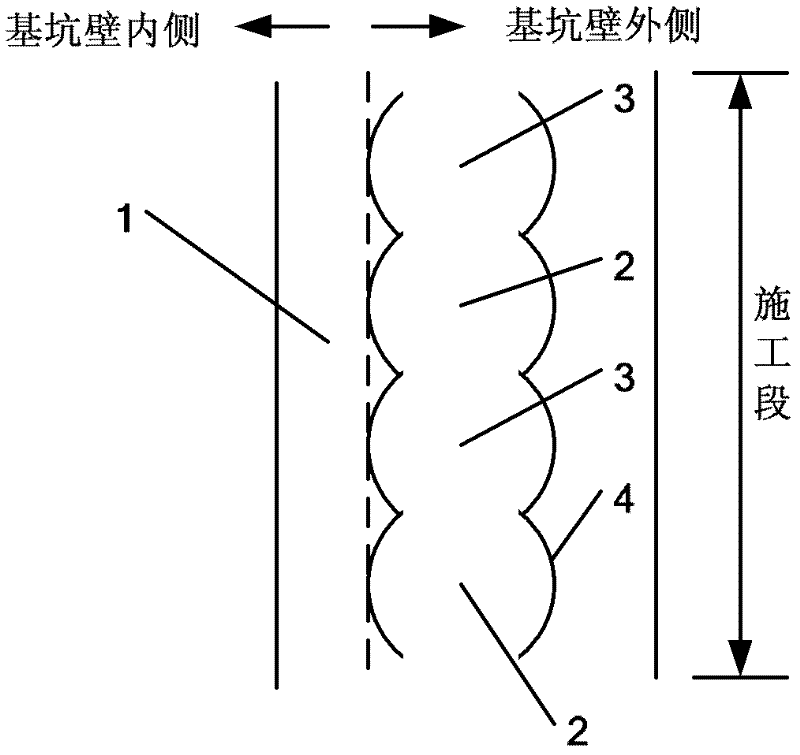

[0023] 101, such as figure 2 As shown, in the construction section above the outer side of the foundation pit wall 1, a guide groove 4 is formed to reserve the construction position 2 of the casing grouting pile and the construction position 3 of the cement mixing pile;

[0024] 102. Carry out cement mixing pile construction to the cement mixing pile construction position 3 in the construction section to form a cement mixing pile. Specifically, repeat the following actions until the cement mixing pile 6 is formed:

[0025] Use the drilling rig to drill the cement mixing pile construction position 3 to the design depth, and then reverse the circulation to lift the drill and spray the cement slurry to a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com