Method for removing and preventing wax of mechanical recovery well by microorganism

A microbial, wax-removing and anti-wax technology, which is applied in chemical instruments and methods, cleaning equipment, earth drilling and mining, etc., can solve the problem of large differences in microbial metabolic activity and quantity, increased consumption of chemical wax-removing and anti-wax agents, and difficulty in forming competition Advantages and other issues, to achieve the effect of low cost, long action period, and extended dosing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the preparation of microorganism clearing and anti-wax composite bacterial agent

[0027] The preparation method of microbial anti-wax bacteria agent is: will be selected from Bacillus cereus (Bacillus cereus) CGMCC No.1141 (referring to CN1236054C, numbering HP), Bacillus subtilis (Bacillus subtilis) CGMCC No.1563 (referring to CN100368532C, numbering HP) L-510) one or several strains of wax-clearing fungus inoculum and selected from bacillus licheniformis (Bacillus licheniformis) CGMCC No.2437 (referring to CN101412979B, number UI-3), short bacillus (Brevibacillus brevis) CGMCC No.1142 (referring to CN1236053C, numbering HT), Potsdam short bacillus (Brevibacillus borstelensis) CGMCC No.2441 (referring to CN101407777A, numbering Po) and fusiform bacillus (Lysinnibacillus fusiformis) CGMCC No.2439 (referring to CN101412980B, numbering #6 ) in one or several anti-wax fungus bacterial agents mixed by weight and number in the formula shown in Table 3, to obta...

Embodiment 2

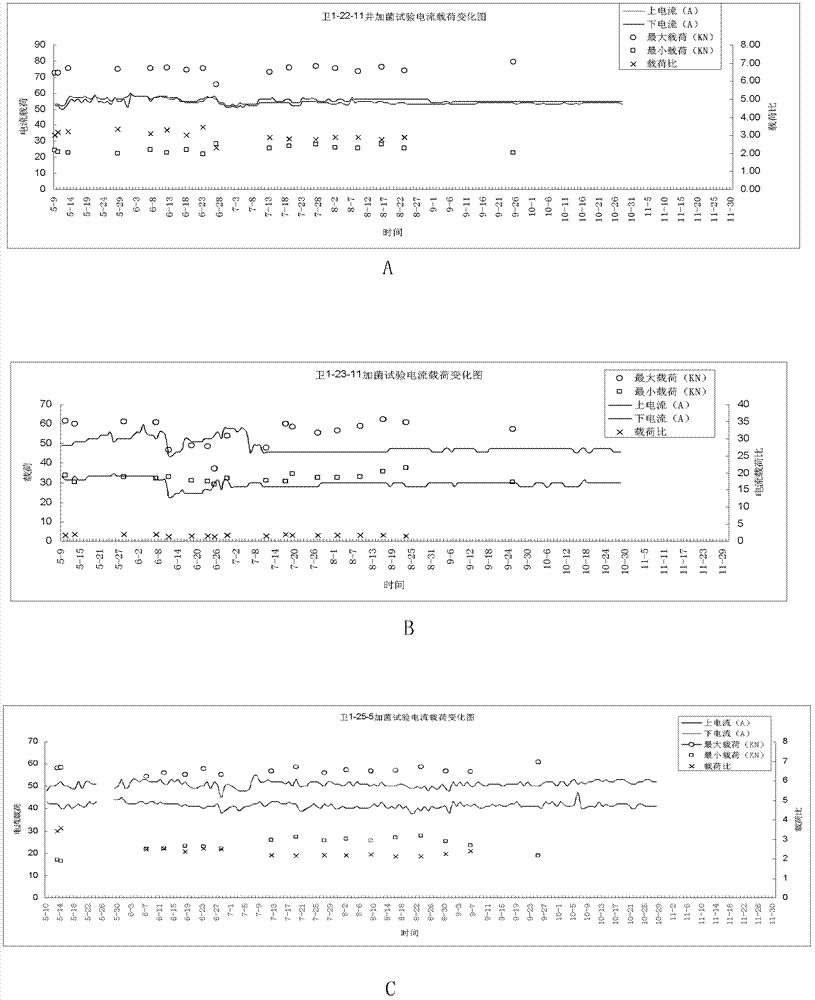

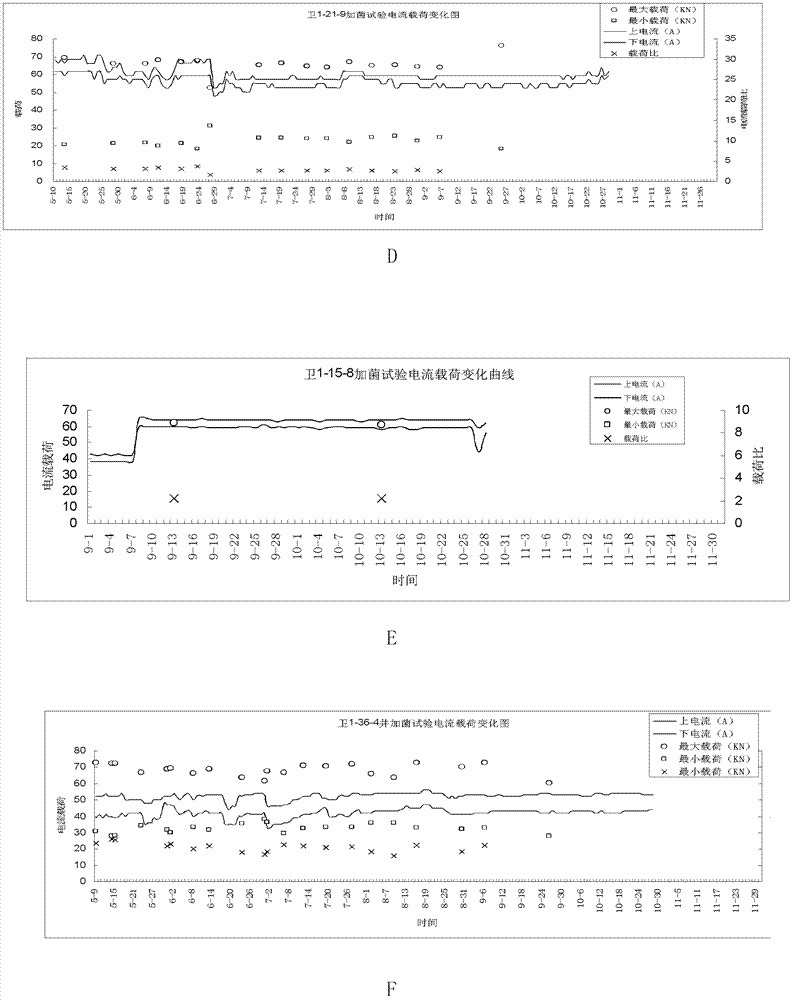

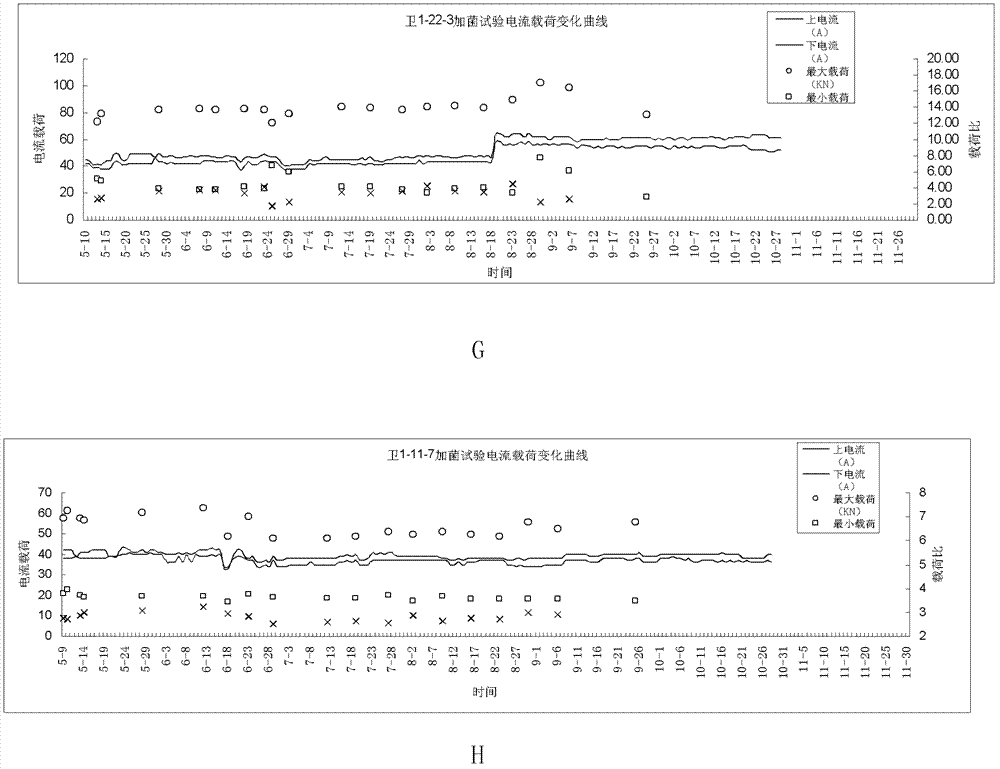

[0030] Embodiment 2, the on-the-spot application and effect evaluation of clearing and preventing wax with microbial compound bacteria agent

[0031] Taking Daqing Peripheral Satellite Oilfield to exploit the Putaohua oil layer as an example to detect the effect of the wax removal and anti-wax method of the present invention, aiming at the physical properties of satellite oilfield crude oil (the average surface crude oil density is 0.867g / cm 3, with a viscosity of 38.5mPa·s, a freezing point of 35.5°C, a wax content of 25.7%, and a glue content of 16.2%) and the performance characteristics of the microbial wax-removing and anti-wax compound bacterial agent, combined with the "Pharmaceutical and Well Washing Plan" for the first area of oil production Statistical Table", select the wells with relatively short dosing cycle, relatively large dosing volume and well washing times on the statistical table, and finally determine 8 test machine production wells, and at the same time g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com