A kind of micro generator and its preparation method

A generator and micro technology, applied in the field of microelectronics, can solve the problems of low energy conversion efficiency, limited application environment, narrow working bandwidth, etc., and achieve the effects of light weight, broad application prospects, and improved output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

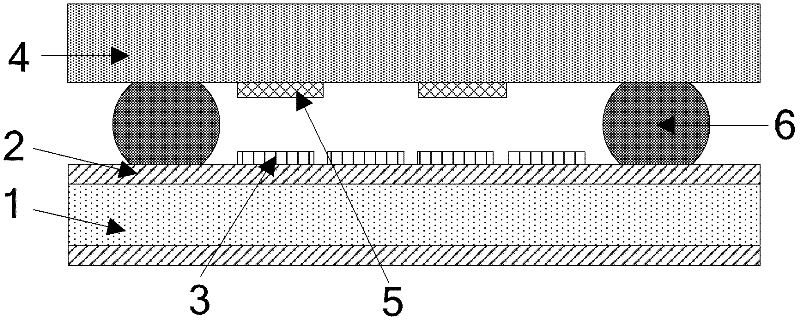

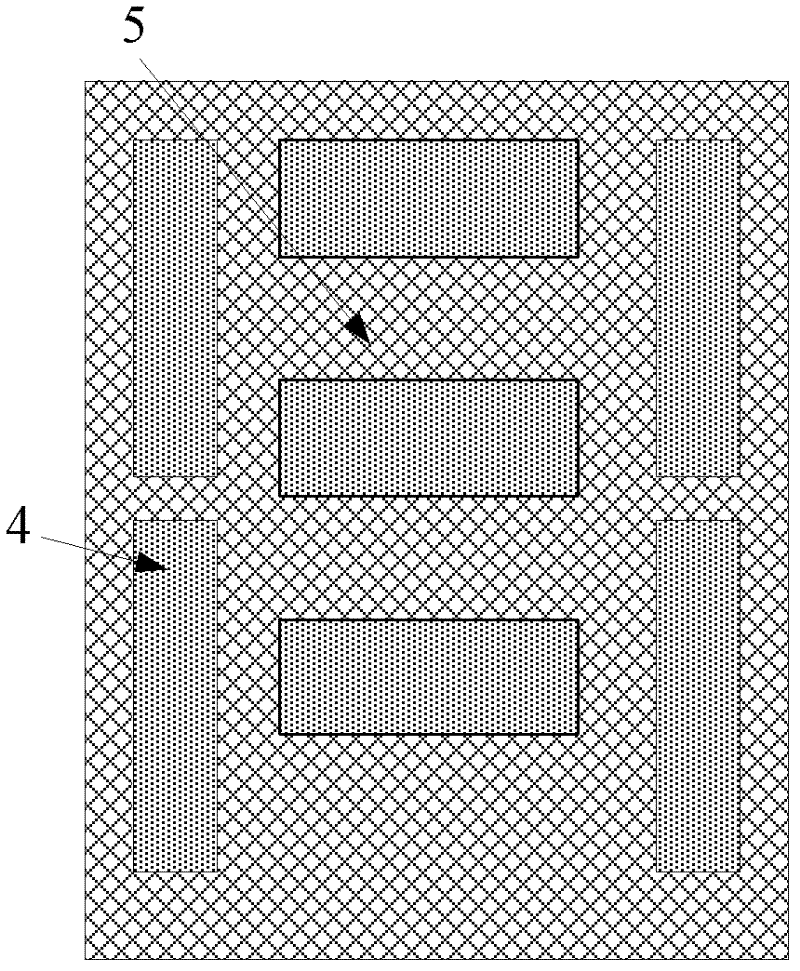

[0044] Embodiment, preparation miniature ball is the SiO of bearing 2 / Si 3 N 4 Composite film electret micro generator

[0045] The technological process of preparing the micro-generator is as follows:

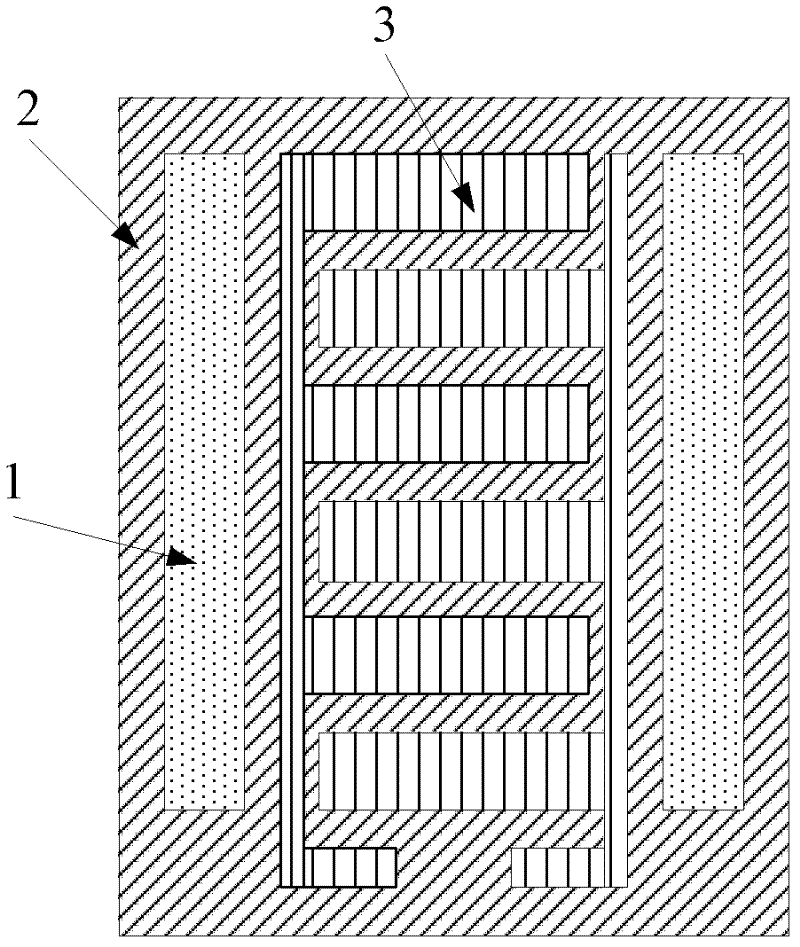

[0046] 1) Collecting electrode structure

[0047] a. Take a single crystal silicon wafer (N(100), double-polished silicon wafer, thickness 400 μm) as the substrate 1 of the collector electrode structure, thermally oxidize to form 300 nm of silicon dioxide, and deposit 110 nm of silicon nitride, photolithography , using reactive ion etching (RIE) dry etching of Si 3 N 4 and SiO 2 , silicon dioxide and silicon nitride double-layer film structure as an insulating layer and etching mask layer 2, see Figure 3 (a).

[0048] b. Lithograph and sputter metal electrodes Cr / Au15nm / 150nm on the insulating layer and corrosion mask layer 2, and use lift-off technology to obtain metal electrodes 3. The width of each finger of the electrode is 2mm, and the length is 20mm. The spacing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com