The preparation method of Liuwei Dihuang Wan

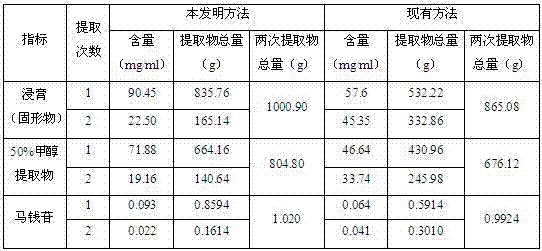

A technology of Liuwei Dihuang Pills and Rehmannia glutinosa, which is applied in the field of preparation of traditional Chinese medicine preparations, can solve the problems of low recovery rate of active ingredients, easy loss of heat-sensitive ingredients, high extraction temperature, etc., and achieve benefits for environmental protection, shorten production cycle, and lower extraction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prescription: Rehmannia glutinosa 8kg, Cornus officinalis 4kg, Cortex Moutan 3kg, Chinese yam 4kg, Poria cocos 3kg, Alisma 3kg

[0034] The preparation method comprises the following steps:

[0035] a. Extraction of peony bark

[0036] a1. Crush the peony cortex of the prescribed amount into coarse powder and set aside;

[0037] a2. The medicinal powder obtained in step a1 is placed in a multifunctional extraction tank, and the volatile oil is extracted by straight-through steam distillation, and the distilled aqueous solution is collected in another device for subsequent use;

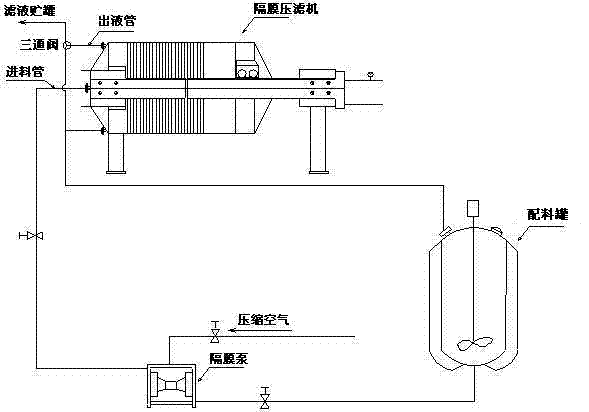

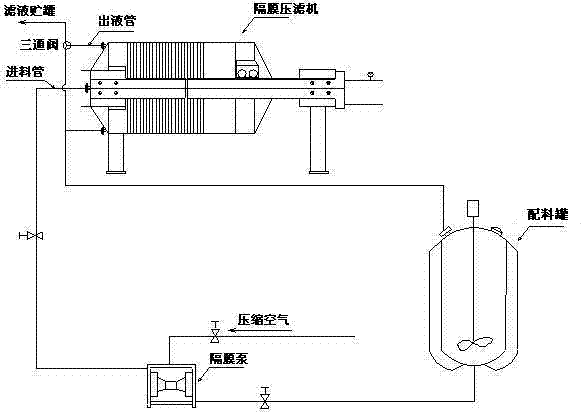

[0038] a3. Add water equivalent to 3 times the weight of Moutan Cortex into the multifunctional extraction tank containing Moutan Cortex dregs, stir and heat to 80°C, keep warm and stir for 5 minutes, and pump the slurry into a diaphragm filter press (80±10 L / m 2 .s polypropylene multifilament filter cloth) for membrane pressure filtration to collect the filter press liquid; after the pr...

Embodiment 2

[0047] Prescription: Rehmannia glutinosa 8kg, Cornus officinalis 4kg, Cortex Moutan 3kg, Chinese yam 4kg, Poria cocos 3kg, Alisma 3kg

[0048] The preparation method comprises the following steps:

[0049] a. Extraction of peony bark

[0050] a1. Crush the peony cortex of the prescribed amount into coarse powder and set aside;

[0051] a2. The medicinal powder obtained in step a1 is placed in a multifunctional extraction tank, and the volatile oil is extracted by straight-through steam distillation, and the distilled aqueous solution is collected in another device for subsequent use;

[0052] a3. Add water equivalent to twice the weight of Moutan Cortex into the multi-functional extraction tank containing Moutan Cortex dregs, stir and heat to 85°C, keep warm and stir for 10 minutes, and pump the slurry into a diaphragm filter press (80±10 L / m 2 .s polypropylene multifilament filter cloth) for membrane pressure filtration to collect the filter press liquid; after the pr...

Embodiment 3

[0061] Prescription: Rehmannia glutinosa 8kg, Cornus officinalis 4kg, Cortex Moutan 3kg, Chinese yam 4kg, Poria cocos 3kg, Alisma 3kg

[0062] The preparation method comprises the following steps:

[0063] a. Extraction of peony bark

[0064] a1. Crush the peony cortex of the prescribed amount into coarse powder and set aside;

[0065] a2. The medicinal powder obtained in step a1 is placed in a multifunctional extraction tank, and the volatile oil is extracted by straight-through steam distillation, and the distilled aqueous solution is collected in another device for subsequent use;

[0066] a3. Add water equivalent to 4 times the weight of Moutan Cortex into the multi-functional extraction tank containing Moutan Cortex dregs, stir and heat to 75°C, keep stirring for 15 minutes, and pump the slurry into a diaphragm filter press (80±10 L / m 2.s polypropylene multifilament filter cloth) for membrane pressure filtration to collect the filter press liquid; after the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com