A kind of treatment method of waste water produced by wet process acrylic fiber in a kind of two-step method

A technology for producing wastewater and treatment methods, which can be used in biological water/sewage treatment, sustainable biological treatment, oxidized water/sewage treatment, etc., and can solve the problems of complex pretreatment, difficult to popularize and use, and harsh operating conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

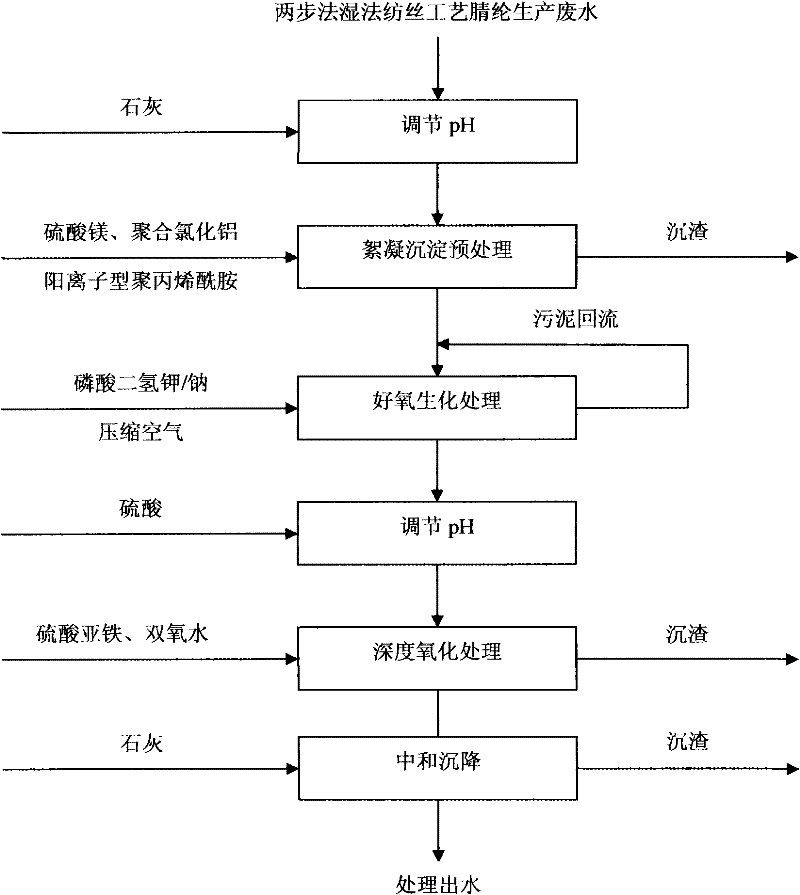

Method used

Image

Examples

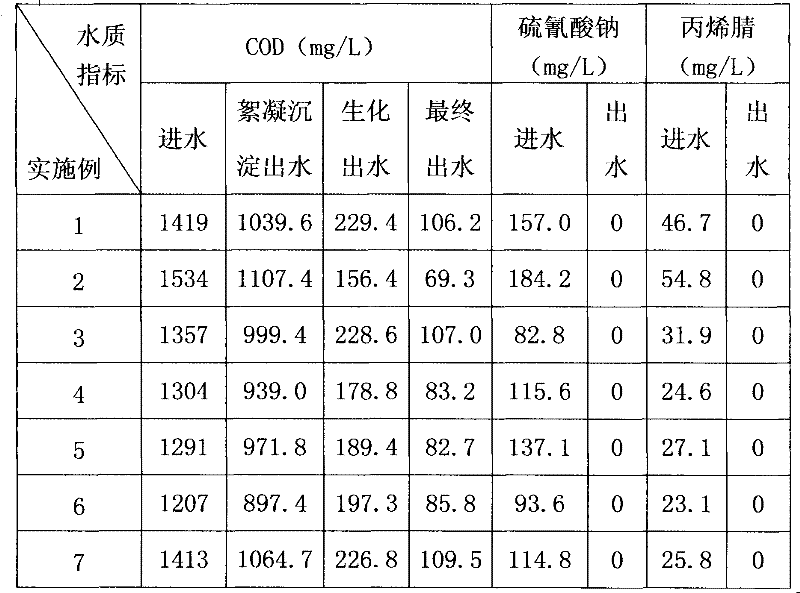

Embodiment 1-7

[0050] In the waste water of two-step wet-process acrylic fiber production in a factory, lime is firstly added to adjust the pH to 6.5; the waste water after pH adjustment first enters the mixing tank 1, and the concentrations of the added magnesium sulfate and PAC in the waste water are 1000mg / L and 200mg respectively / L, then enter the mixing tank 2, add PAM and its concentration in wastewater is 8mg / L.

[0051] The wastewater after flocculation and sedimentation treatment enters the aerobic biochemical tank, and 45mg / L of potassium dihydrogen phosphate is added to the wastewater; the dissolved oxygen is about 4mg / L, the water temperature of the biochemical tank is 20-30°C, and the sludge concentration is 8±1g / L, 70% of which is fixed on the surface of the semi-soft fiber filler, and 30% is suspended in the sewage; the hydraulic retention time is 18h.

[0052] The supernatant after the biochemical treatment enters the Fenton oxidation advanced treatment tank, after adding s...

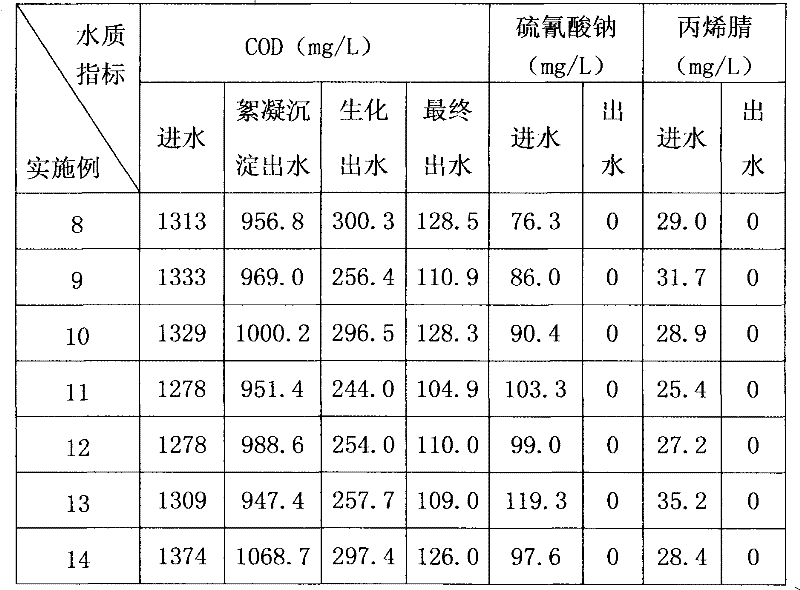

Embodiment 8-14

[0057] A factory two-step wet process acrylic fiber production waste water, adopts the same treatment process as embodiment 1.

[0058] Among the operating parameters, the addition of magnesium sulfate in the flocculation precipitation is 980mg / L, the addition of PAC is 250mg / L, the addition of PAM is 10mg / L, the hydraulic retention time of the biochemical treatment tank is 12h, and the Fe in the Fenton oxidation 2+ Dosage 1000mg / L, H 2 o 2 The addition amount is 4000mg / L, the reaction time is 5h, other is the same as embodiment 1. See Table 3 for the processing results.

[0059] table 3

[0060]

[0061] The appearance of the effluent in the table is colorless and transparent, pH6-9, COD<160mg / L, which meets the national first-level discharge standard of the acrylic fiber industry, and the acrylonitrile and sodium thiocyanate in the effluent are lower than the detection limit.

Embodiment 15-20

[0063] A factory two-step wet process acrylic fiber production waste water, adopts the same treatment process as embodiment 1.

[0064] Among the operating parameters, among the operating parameters, the addition of magnesium sulfate in the flocculation precipitation is 950mg / L, the addition of PAC is 150mg / L, the addition of PAM is 7mg / L, the hydraulic retention time of the biochemical treatment tank is 16h, and the Fe in the Fenton oxidation 2+ Dosage 950mg / L, H 2 o 2 The addition amount is 3600mg / L, the reaction time is 5h, other is the same as embodiment 1. See Table 4 for the processing results.

[0065] Table 4

[0066]

[0067] The appearance of the effluent in the table is colorless and transparent, pH6-9, COD<160mg / L, and acrylonitrile and sodium thiocyanate in the effluent are below the detection limit.

[0068] The test shows that the effluent COD of this treatment method reaches the national first-level discharge standard of the acrylic fiber industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com