Method for extracting glucoraphanin compound from broccoli and cauliflower

A technology of glucoraphanin and compounds, which is applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the problems of dependence on foreign imports, high prices, and few types of glucosinolate products, and achieve high extraction yields, The effect of low cost, single component and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

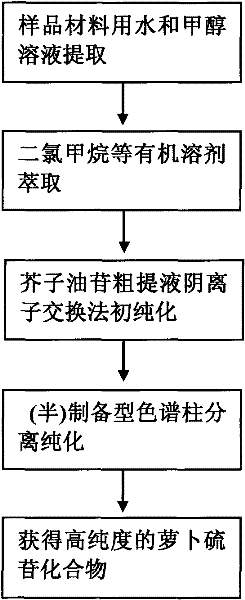

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: (the method utilizing broccoli seed to extract glucoraphanin)

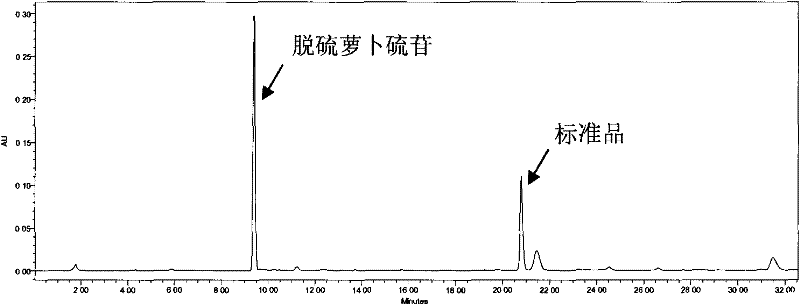

[0034] (1) Selection and pretreatment of broccoli seed materials: refer to Sun et al., Food Chemistry, (2011) method, select glucoraphanin and account for more than 90% of the total fatty glucosinolates and account for 80% of the total glucosinolates The above broccoli seeds are used as ingredients (see figure 2 ), under the premise of avoiding physical damage such as cutting, squeezing, abrasion and crushing, wash with water twice to remove surface pollutants and impurities, drain and set aside;

[0035] (2) Extraction reagent, crude and concentrated: using methanol as the extraction reagent of glucoraphanin, the extraction reagent and broccoli seeds are extracted repeatedly by the same process of 2.5L:1kg by volume and weight at 85°C, stirring and soaking for 20min. After three times, filter through Whatman2 filter paper respectively, and then ultrafiltration through 0.45 μm and 0.22 μm fi...

Embodiment 2

[0039] Embodiment 2: (the method utilizing broccoli sprouts to extract glucoraphanin)

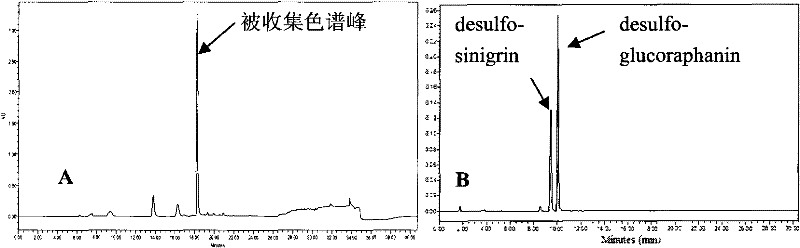

[0040] In this example, the material in step (1) is broccoli sprouts that have germinated for 3-4 days, the extraction solvent used in step (2) is water, the extraction temperature is 100°C, the extraction time is 25min, and the ratio of extraction reagent to material is 1L : 1kg, repeated extraction 3 times, the sample after freeze-drying is dissolved in the water of 1.5% extraction reagent volume; In the step (3), the impurity removal method is 13200g centrifugal 10min under 4 ℃; In the step (4), the soaking liquid used is 85% Methanol, the soaking time is 15h, the cleaning solution is 5% methanol of 5 times the volume of the column bed, and 20% acetonitrile solution equal to the volume of the column bed is used as the eluent for eluting; the eluent is 3 times the volume of the column bed containing 0.5 The 5% acetonitrile solution of M sodium chloride; Step 5 adopts preparative chromatog...

Embodiment 3

[0041] Embodiment 3: (the method utilizing cauliflower sprouts to extract glucoraphanin)

[0042] In this example, the material used in step (1) is broccoli stems and leaves, the extraction solvent used in step (2) is 80% methanol, the extraction temperature is 90°C, the extraction time is 25min, and the ratio of extraction reagent to material is 1L: 2kg, The extraction was repeated 3 times, and the freeze-dried sample was dissolved in 1.0% water of extraction reagent volume; the impurity removal method in step (3) was to filter with 0.45 μm and 0.22 μm ultrafiltration membranes; the soaking liquid used in step (4) was 90 % methanol, the soaking time is 20h, the cleaning solution is 10% methanol of 4 times the volume of the column bed, and 20% isopropanol of the same column bed volume is used as the eluent for eluting; the eluent is 2 times the volume of the column bed Containing 20% isopropanol solution of 0.5M potassium chloride; Adopt preparative chromatographic column in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com