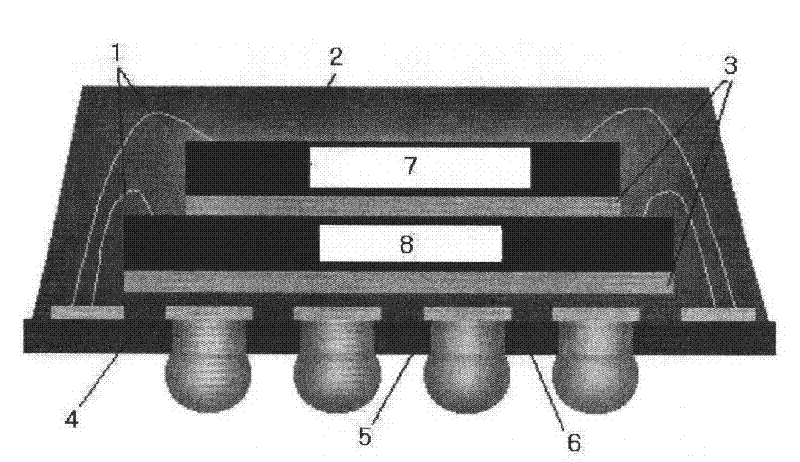

Thermosetting double-sided adhesive film with excellent adhesive properties and heat resistance

A technology of adhesive performance and adhesive film, applied in the direction of film/sheet adhesive, adhesive type, heat-activated film/sheet, etc., can solve the problems of interface peeling, popcorn bursting, etc., and achieve Effects of preventing peeling of the interface, excellent adhesive performance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

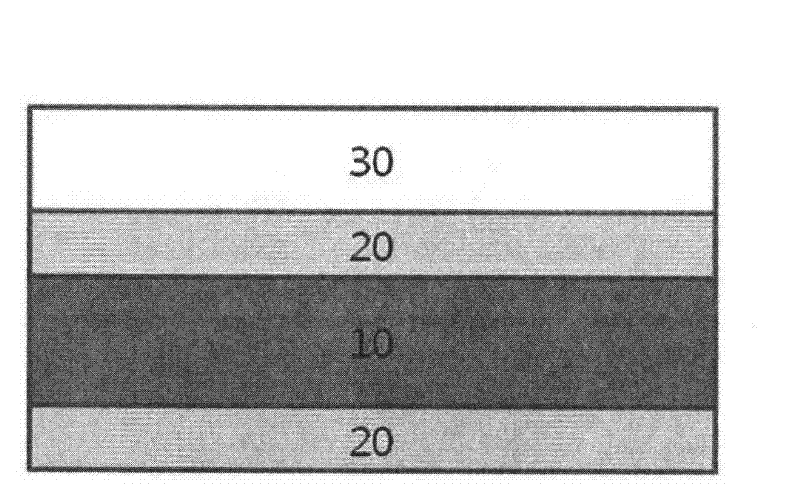

Method used

Image

Examples

Embodiment 1

[0041]First, 50 parts by weight of novolac epoxy resin (epoxy equivalent 199), 150 parts by weight of phenolic resin represented by the following structural formula 1, and 10 parts by weight of hexamethoxymethylmelamine and 10 parts by weight of o-phthalic acid as curing agent Diformic anhydride was added to 120 parts by weight of NBR (containing 27% by weight of acrylonitrile and 5% by weight of carboxyl groups). Then 2 parts by weight of dicumyl peroxide as a rubber crosslinking agent was added, and by using an acetone solvent, the amount of acetone was adjusted so that the viscosity became 400CPS. After all the components in the solution prepared above were dissolved at room temperature, this adhesive solution was coated on both sides of a polyimide film having a thickness of 25 μm so that the thickness after drying was 12 μm. After a drying step (drying at 150° C. for 3 minutes), a polyethylene terephthalate film having a thickness of 38 μm was laminated thereon to prepare...

Embodiment 2

[0045] In the same manner as in Example 1, an adhesive solution prepared from the same composition as in Example 1 was used to manufacture an adhesive film, except that the phenolic resin shown in the following structural formula 2 was used instead of the phenolic resin used above. .

[0046] (Structural formula 2, softening point: 85°C)

[0047]

Embodiment 3

[0049] In the same manner as in Example 1, an adhesive solution prepared from the same composition as in Example 1 was used to manufacture an adhesive film, except that the phenolic resin shown in the following structural formula 3 was used instead of the phenolic resin used above. .

[0050] (Structure 3)

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com