A method for producing high-purity intracellular glycopeptides of versicolor versicolor by using modern fermentation technology

A technology of versicolor intracellular glycopeptide and fermentation tank, which is applied in the direction of peptide preparation method, microorganism-based method, biochemical equipment and method, etc., can solve the problem of low yield of versicolor intracellular glycopeptide, and achieve reduction Effect of heating extraction time, benefiting yield, improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

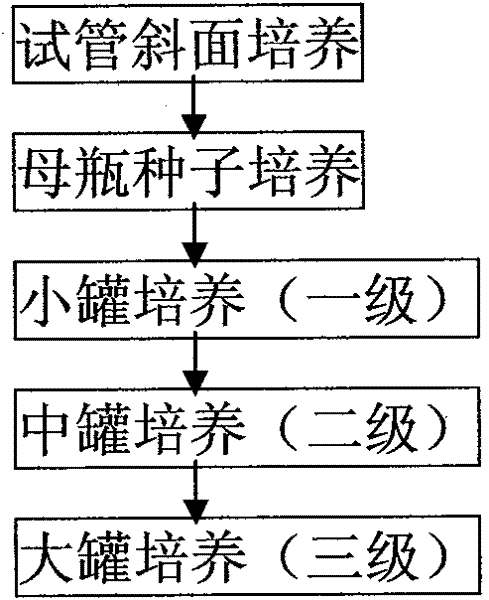

[0036] The seed solution was prepared from the slant culture of the strain CVDX-1 through two-layer liquid aerated fermentation culture.

[0037]Incline medium (g / L): glucose 20, yeast extract 5, agar 15, prepared with drinking water, pH natural. Sterilize at 119°C for 30 minutes, connect the preserved strain CVDX- to the culture medium, and cultivate it in a 25°C incubator for 7 days.

[0038] Mother bottle medium (g / L): Glucose 20, yeast powder 10, licicine 2, magnesium sulfate 5, zinc sulfate 5, prepared with drinking water, PH natural. Sterilize at 119°C for 30 minutes, and culture on a reciprocating shaker (60 times / min) in a culture room for 6 days after inoculation, at a culture temperature of 25°C.

[0039] Small tank medium (g / L): glucose 15, soybean powder 15, dextrin 100, magnesium sulfate 5, potassium dihydrogen phosphate 5, calcium carbonate 2. Sterilize at 119°C for 30 minutes, 10 liters of fully automatic stainless steel fermentation tank, The feeding amount i...

Embodiment 2

[0044] The seed solution was prepared from the slant culture of the strain CVDX-1 through two-layer liquid aerated fermentation culture.

[0045] Incline medium (g / L): glucose 20, yeast extract 5, agar 15, prepared with drinking water, pH natural. Sterilize at 122°C for 30 minutes, connect the preserved strain CVDX-1 to the culture medium, and cultivate it in a 28°C incubator for 5 days.

[0046] Mother bottle medium (g / L): Glucose 20, yeast powder 10, licicine 2, magnesium sulfate 5, zinc sulfate 5, prepared with drinking water, PH natural. Sterilize at 123°C for 30 minutes, and culture on a reciprocating shaker (60 times / min) in a culture room for 5 days after inoculation at a culture temperature of 28°C.

[0047] Small tank medium (g / L): glucose 15, soybean powder 15, dextrin 100, magnesium sulfate 5, potassium dihydrogen phosphate 5, calcium carbonate 2. Sterilize at 122°C for 30 minutes, 10 liters of fully automatic stainless steel fermentation tank, The feeding amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com